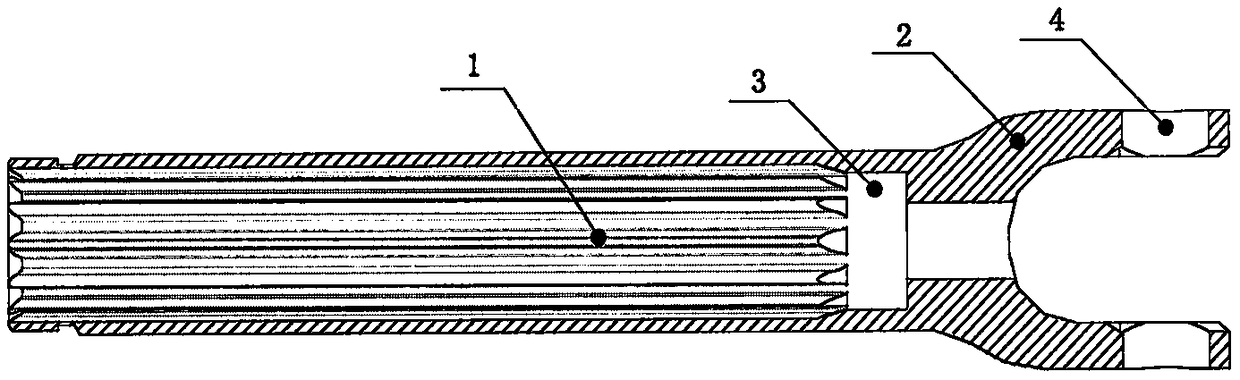

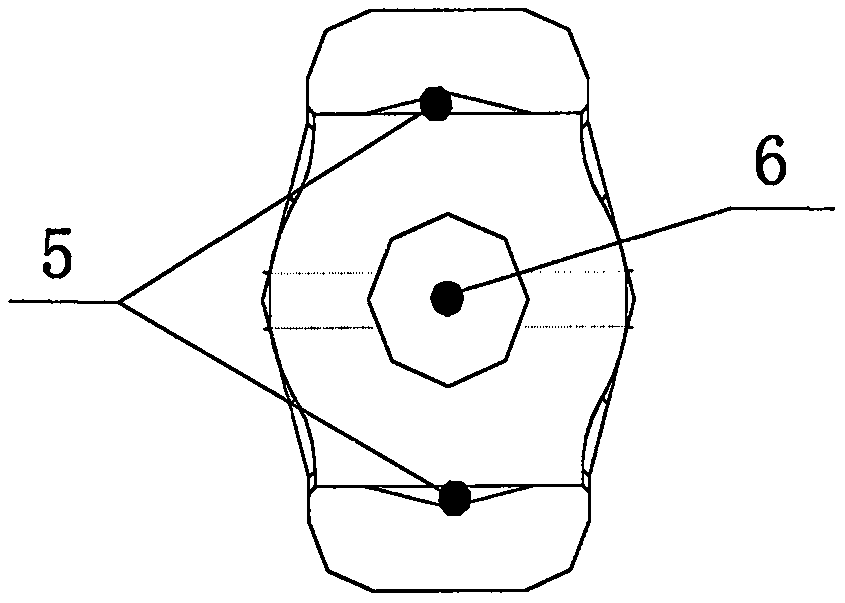

Vehicle universal joint fork overall part cold extrusion compression molding process

A universal joint fork and press forming technology, applied in the field of auto parts manufacturing, can solve the problems of stress deformation of parts, low product qualification rate, high crack rejection rate, and achieve the effect of improving strength, high dimensional accuracy and protecting molecular structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

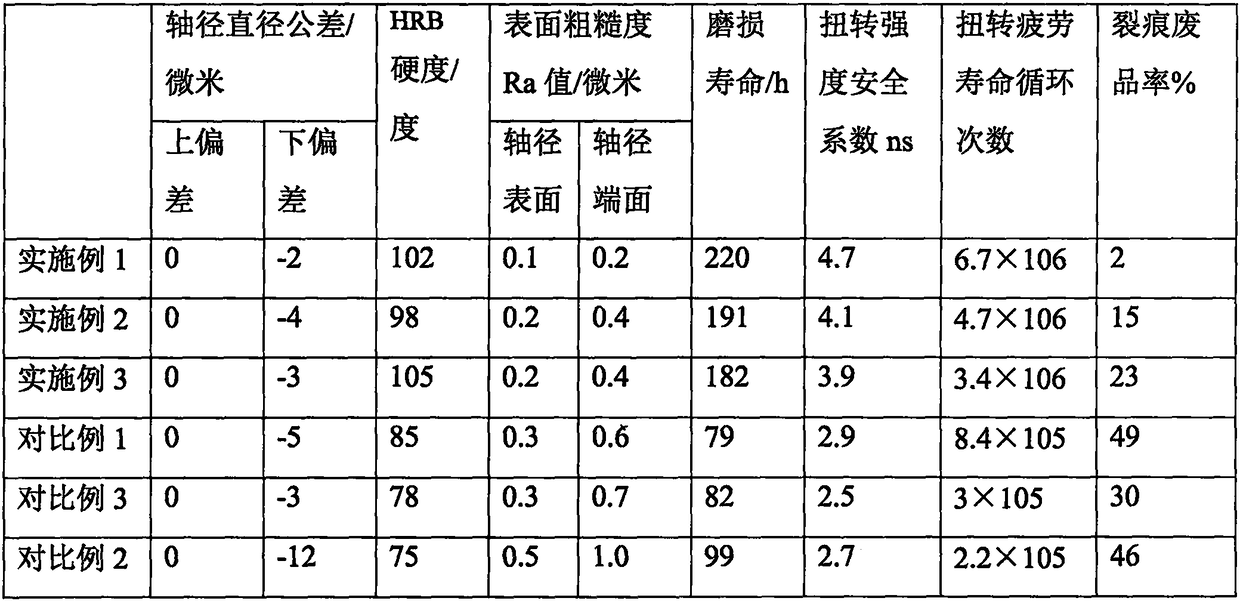

Embodiment 1

[0043] A cold extrusion press forming process for an integral part of an automobile universal joint fork, specifically comprising the following steps:

[0044] Step 1, cutting and blanking: cutting and blanking the round bar into required size; the HRB hardness of the round bar is 90 degrees;

[0045] Step 2, annealing: Put the cut bar into the box-type annealing furnace and heat it to 800 degrees, then keep it warm for 2 hours, and then release it when it is cooled to 550 degrees with the box-type annealing furnace, and then air-cool to room temperature; HRB after annealing Hardness at 78 degrees;

[0046] Step 3. Shot blasting: Put the product into the shot blasting machine, use No. 80 steel grit, and blast it for 18 minutes to remove the oxide layer and a small amount of burrs on the surface;

[0047] Step 4, phosphorus saponification treatment:

[0048] Step 4-1. First, wash the workpiece after shot blasting with water and put it in a phosphating solution at 65 degrees C...

Embodiment 2

[0061] A cold extrusion press forming process for an integral part of an automobile universal joint fork, specifically comprising the following steps:

[0062] Step 1, cutting and blanking: cutting and blanking the round bar into required size; the HRB hardness of the round bar is 90 degrees;

[0063] Step 2, annealing: Put the cut bar into the box-type annealing furnace and heat it to 800 degrees, then keep it warm for 2 hours, and then release it when it is cooled to 550 degrees with the box-type annealing furnace, and then air-cool to room temperature; HRB after annealing Hardness at 78 degrees;

[0064] Step 3. Shot blasting: Put the product into the shot blasting machine, use No. 80 steel grit, and blast it for 18 minutes to remove the oxide layer and a small amount of burrs on the surface;

[0065] Step 4, phosphorus saponification treatment:

[0066] Step 4-1. First, wash the workpiece after shot blasting with water and put it into a phosphating solution at 55 degrees...

Embodiment 3

[0079] A cold extrusion press forming process for an integral part of an automobile universal joint fork, specifically comprising the following steps:

[0080] Step 1, cutting and blanking: cutting and blanking the round bar into required size; the HRB hardness of the round bar is 90 degrees;

[0081] Step 2, annealing: Put the cut bar into the box-type annealing furnace and heat it to 800 degrees, then keep it warm for 2 hours, and then release it when it is cooled to 550 degrees with the box-type annealing furnace, and then air-cool to room temperature; HRB after annealing Hardness at 78 degrees;

[0082] Step 3. Shot blasting: Put the product into the shot blasting machine, use No. 80 steel grit, and blast it for 20 minutes to remove the oxide layer and a small amount of burrs on the surface;

[0083] Step 4, phosphorus saponification treatment:

[0084] Step 4-1. First, wash the workpiece after shot blasting with water and put it in a phosphating solution at 55 degrees C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com