Effective drainage method and system for flow division well

A discharge system and shunt well technology, applied in waterway systems, sewage discharge, drainage structures, etc., can solve the problems of electric shock hazard, easy leakage, difficult power supply, etc., and achieve no occupation of height space, strong anti-blocking ability, mature The effect of reliable prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

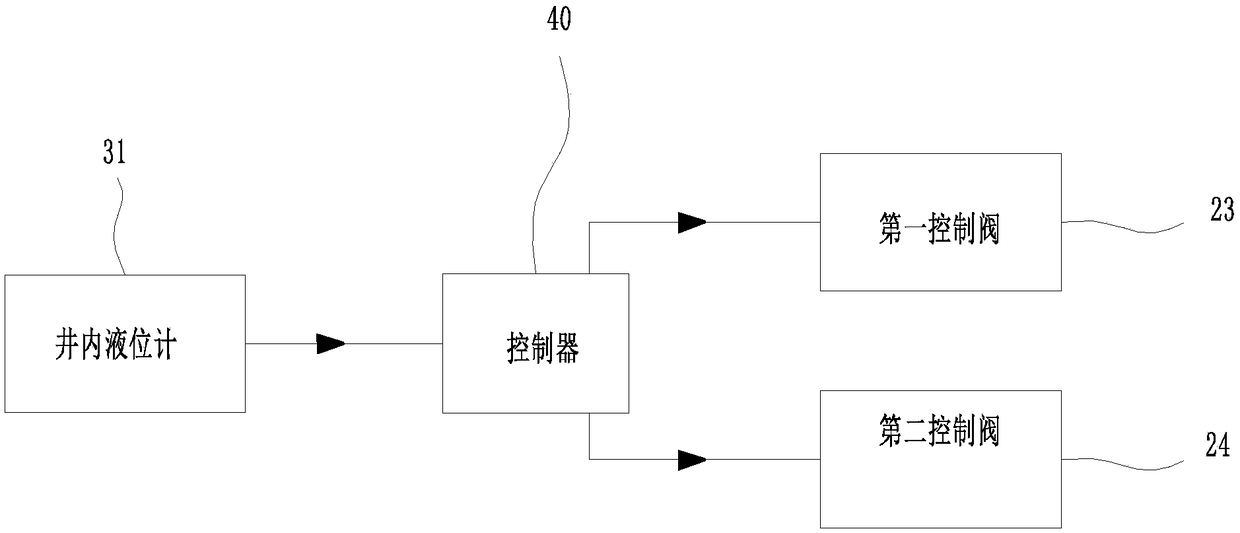

[0070] see image 3 As shown, the embodiment of the present invention provides an effective drainage method for the diversion well, as follows:

[0071] Set the first warning liquid level H0 in the well of the shunt well, and continuously collect the liquid level H in the shunt well, wherein,

[0072] On sunny days, the first pneumatic shut-off device is inflated, and the first water outlet pipe is closed;

[0073] After rainfall, when diverting dirty rainwater, H

[0074] When H≥H0, control the first pneumatic shut-off device to start deflation, and the opening of the first water outlet pipe gradually increases as time goes on;

[0075] Before the first water outlet pipe is fully opened, if the liquid level in the shunt well drops to H

[0076] When diverted clean rainwater enters the natural...

Embodiment 2

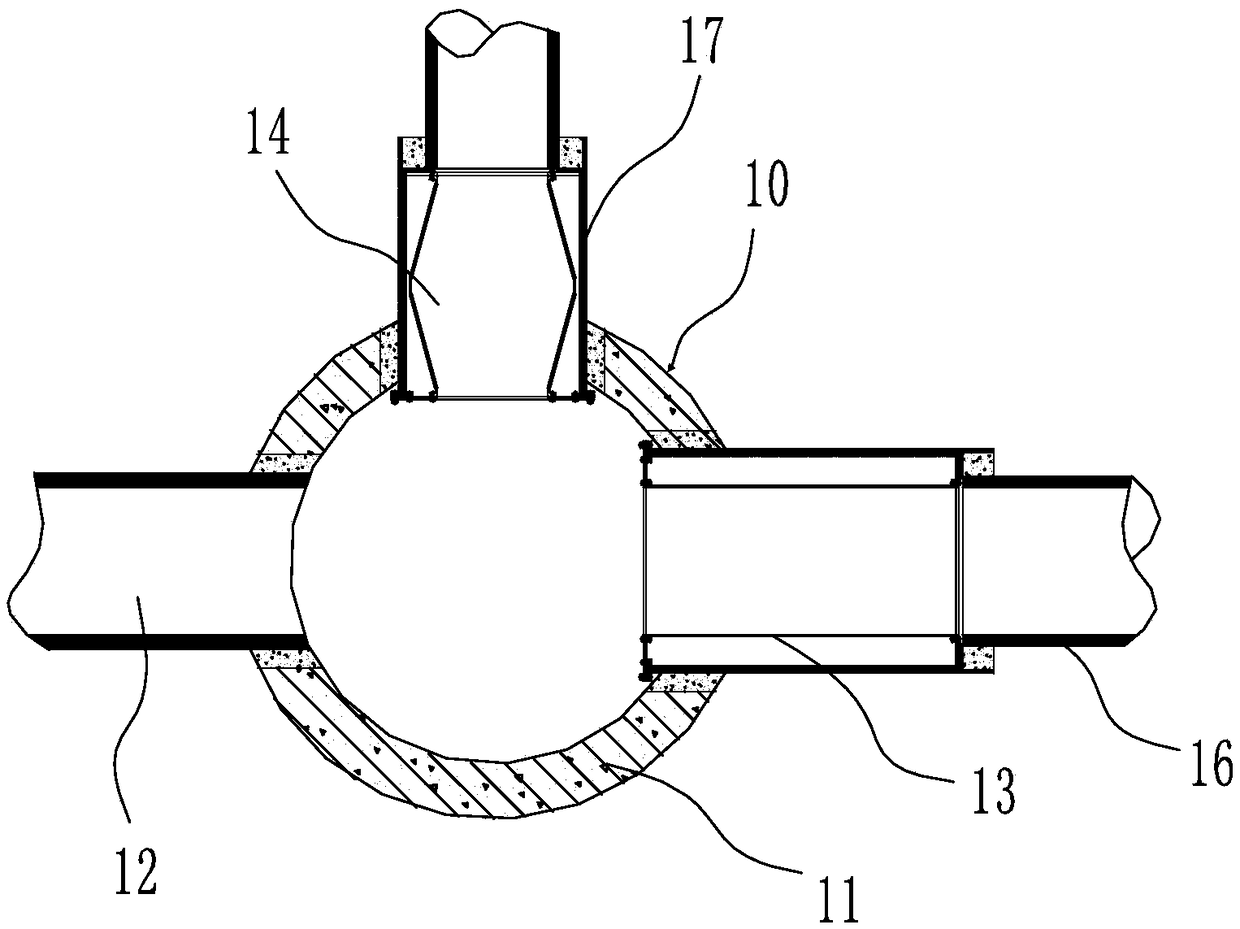

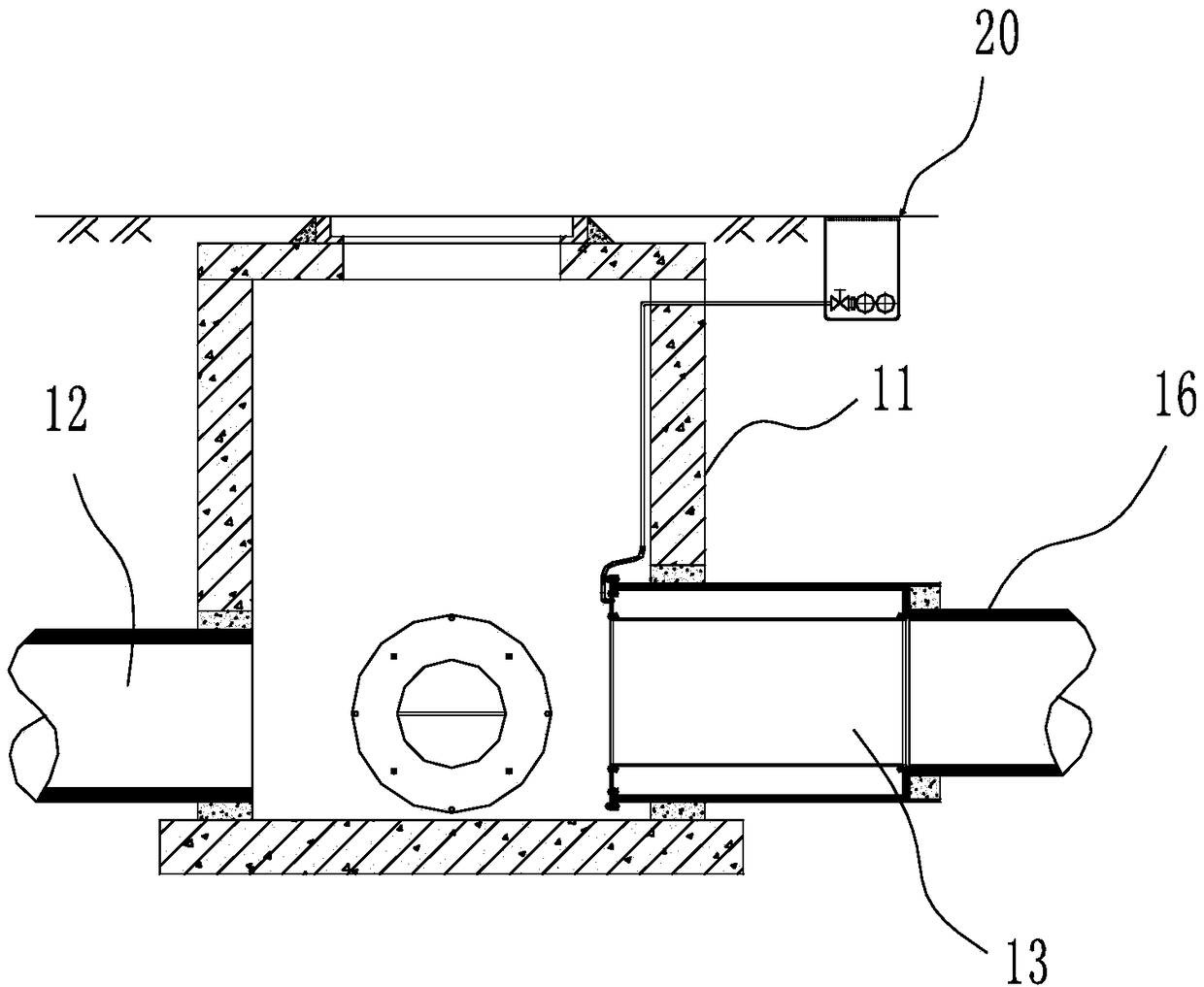

[0083] see figure 1 , figure 2 , image 3 , an effective drainage system for a diversion well, comprising: a compressed gas source, a gas delivery pipe, a control valve 20, a liquid level gauge 31 in the well and a pneumatic diversion well 10.

[0084] Wherein, the pneumatic diversion well 10 comprises a diversion well body 11 and a pneumatic shut-off device and a well liquid level gauge 31 arranged in the diversion well body 11,

[0085] The diversion well body is provided with a water inlet 12 and at least two water outlets, which are respectively the first water outlet and the second water outlet. The first water outlet is connected to the natural water body or rainwater pipe through the first outlet pipe 16, and the second water outlet is The second outlet pipe 17 is connected to the sewage pipe or the sewage treatment facility or the storage tank or the initial rain pipe or the sewage treatment facility, and at least two pneumatic intercepting devices are set on the fi...

Embodiment 3

[0099] see Figure 4 , Figure 5 and Figure 6 As shown, on the basis of embodiment 2, the body of the diversion well 10 in the present embodiment is provided with a water inlet 12, a first water outlet, a second water outlet and a third water outlet, and the first water outlet passes through the first water outlet. Outlet pipe 16 is connected to natural water body or rainwater pipe, and the second water outlet is connected to sewage pipe or sewage treatment facility or storage tank through second outlet pipe 17, and the third water outlet is connected to primary rain pipe or storage tank through the third outlet pipe 18 or Sewage treatment facilities, on the second outlet pipe 17 and the third outlet pipe 18, the pneumatic shut-off devices are respectively the second pneumatic shut-off device and the third pneumatic shut-off device, and each pneumatic shut-off device passes through a gas delivery sub-pipeline and gas delivery respectively. The main pipe is connected, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com