Electric field-assisted ceramic material sintering furnace and control method thereof

A ceramic material, electric field assisted technology, used in furnace control devices, electric furnace heating, furnaces, etc., can solve the problems of high sintering temperature, high energy consumption, long sintering time, etc., to reduce the sintering temperature of ceramics, achieve densification, and save energy. The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

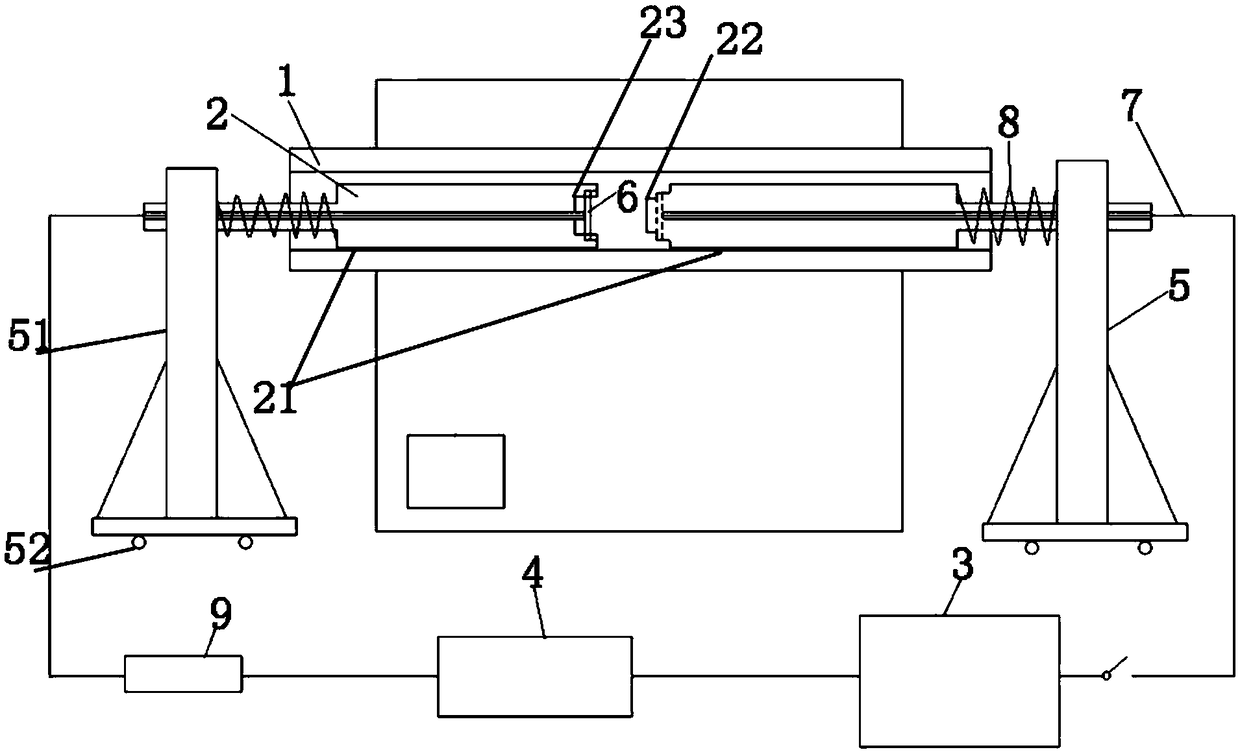

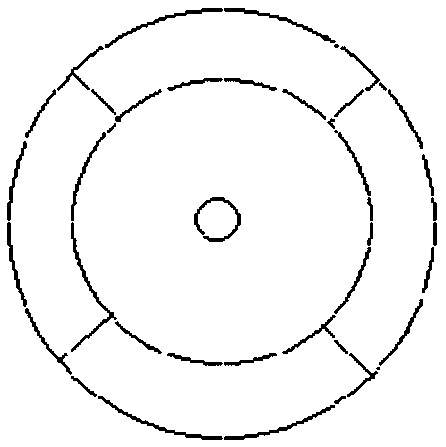

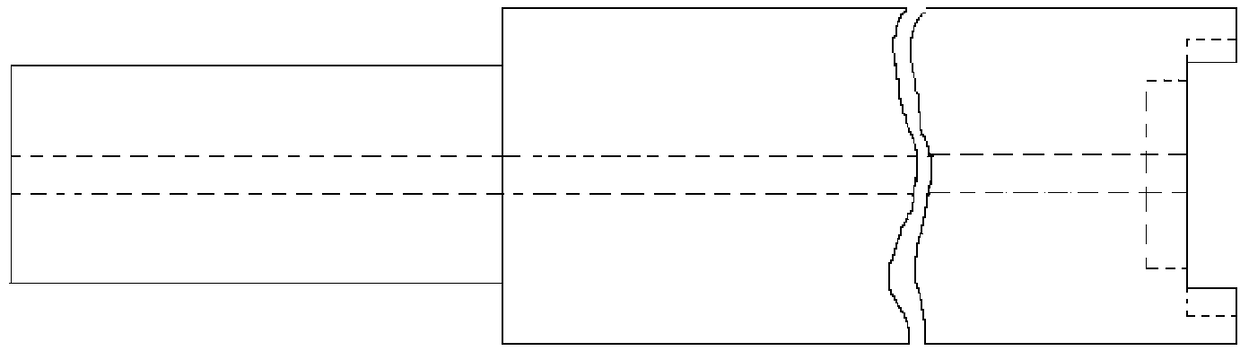

[0052] This embodiment provides a ceramic material sintering furnace assisted by an electric field, which includes a tube furnace 1 with a shell on the outside, and a time and furnace temperature control unit on the shell. The tube furnace can be realized through the time and furnace temperature control unit. According to the presetting of the heating program of the body, the prepared PZT ceramic powder is uniaxially pressed into a cylindrical shape, and the two ends are coated with platinum slurry for use. Put the PZT ceramic sample coated with platinum paste on the front end of the alumina ceramic tube 2 on one side, and a platinum sheet 6 is installed at the front end, and lightly stick the sample on the platinum sheet 6, and the platinum wire 7 passes through the ceramic tube 2 and the platinum sheet 6 connected, the other end stretches out the ceramic tube 2, the spring 8 is placed between the ceramic tube 2 and the support frame 51, one end is against the step of the cera...

Embodiment 2

[0055] This embodiment provides a ceramic material sintering furnace assisted by an electric field. The difference between this embodiment and Embodiment 1 is that the sample to be processed is made of Al 2 o 3 For ceramic materials, the applied voltage is set to 1400V through the electric field applying device 3, and the final furnace temperature is 1400°C.

[0056] Figure 5 Al is prepared for sintering under this condition 2 o 3 From the SEM photo of the ceramic, it can be seen that the sample has been completely densified. Compared with the traditional sintering method, adopting the sintering furnace provided by the present invention, Al 2 o 3 The sintering temperature of the ceramic material is reduced by about 300°C, and the sintering time is reduced from several hours to 30s.

Embodiment 3

[0058] This embodiment provides a ceramic material sintering furnace assisted by an electric field. The difference between this embodiment and Embodiment 1 is that the sample to be processed is made of KNN ceramic material, and the applied voltage is set to 1400V by the electric field application device 3, and the final furnace temperature is 750°C.

[0059] Image 6 SEM photos of KNN ceramics prepared by sintering under this condition, it can be seen that the samples are completely densified. Compared with the traditional sintering method, with the sintering furnace provided by the present invention, the sintering temperature of the KNN ceramic material is reduced by about 300°C, and the sintering time is reduced from several hours to 30s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com