Analysis system for online detection of performance and fault of gearbox

A fault analysis and gearbox technology, which is applied in the testing of machine gears/transmission mechanisms, measuring devices, and testing of mechanical components, etc., can solve the problems of inability to detect gearboxes, power transmission chain failure and shutdown, and machine crashes. The effect of speeding up testing, grabbing market share, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

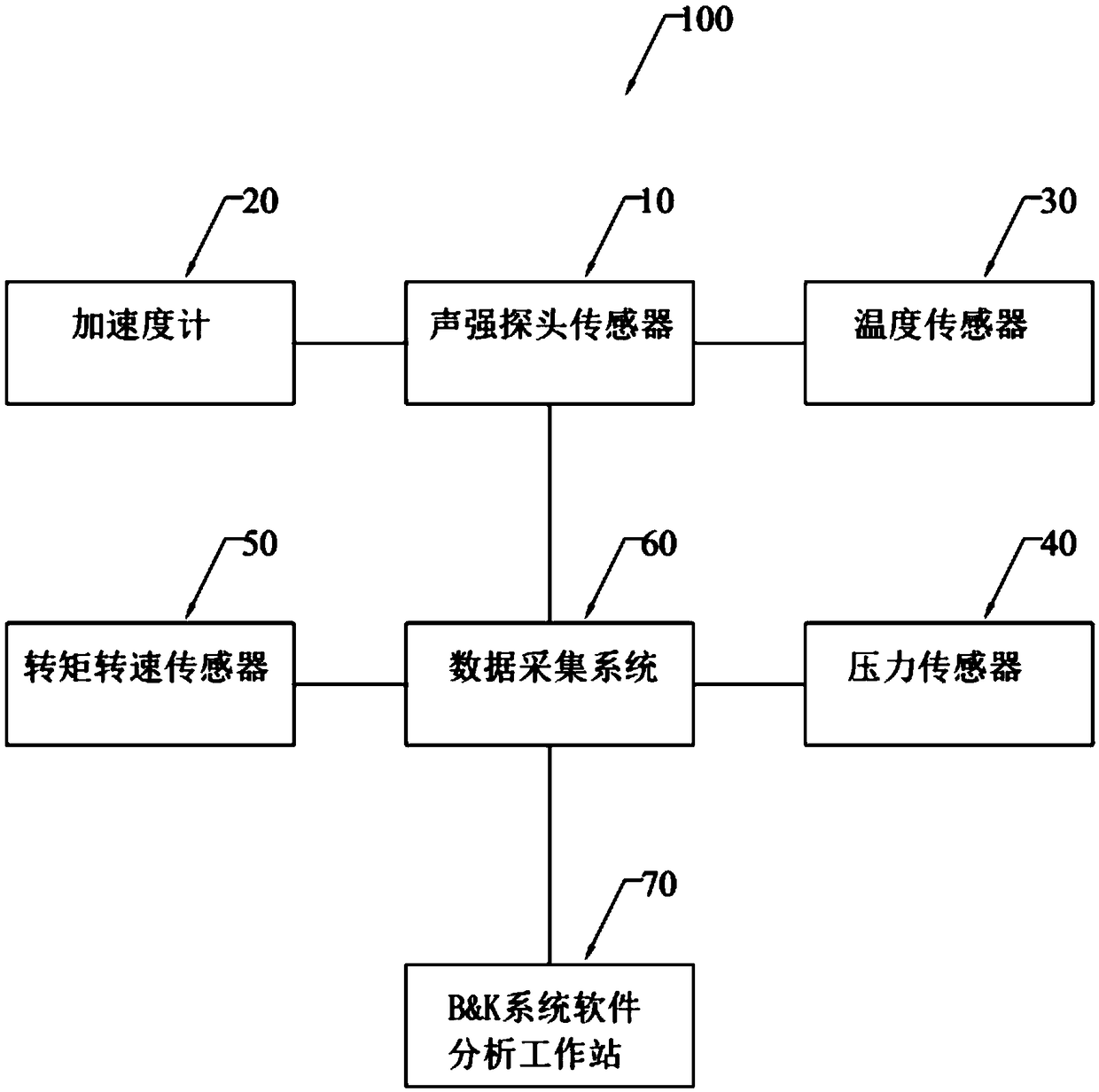

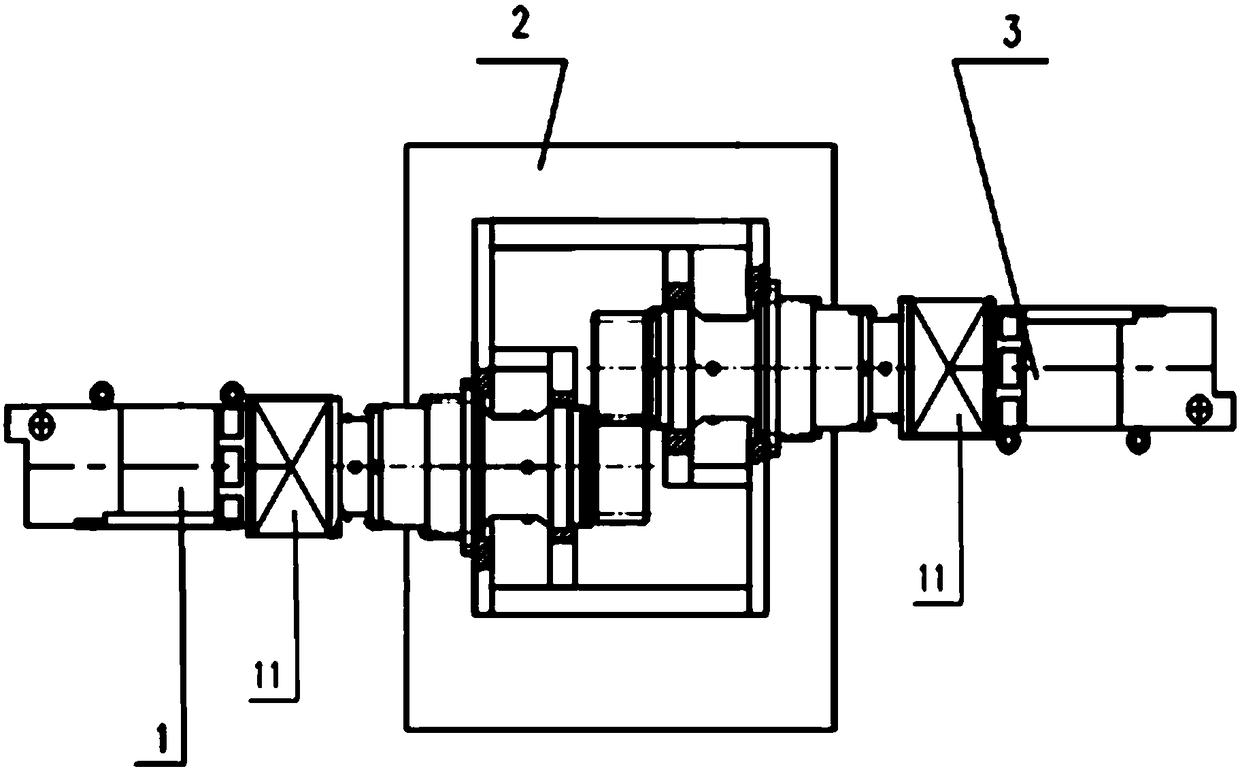

[0022] Such as Figure 1 to Figure 2 As shown, an on-line gearbox performance detection and fault analysis system 100 includes: a sound intensity probe sensor 10, an accelerometer 20, a temperature sensor 30 for collecting temperature data when the gearbox is running, a pressure sensor 40, and a torque speed sensor 50 , data acquisition system 60 and B&K system software analysis workstation 70, data acquisition system 60 and sound intensity probe sensor 10, accelerometer 20, temperature sensor 30, pressure sensor 40, torque speed sensor 50 form communication connection to carry out data magnetic pole; The collection system 60 uploads the collected data to the B&K system software analysis workstation 70 . The sound intensity probe sensor 10 is used to collect noise data when the gearbox is running. The accelerometer 20 is used to collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com