Asphalt density and relative density measuring method based on weighing method

A technology of relative density and measurement method, applied in specific gravity measurement, measurement devices, instruments, etc., can solve the problems of large measurement error, large influence of air measurement results, difficult operation of asphalt density and relative density measurement, etc., and achieve the error of test results. Small size, reduced measurement environment requirements, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

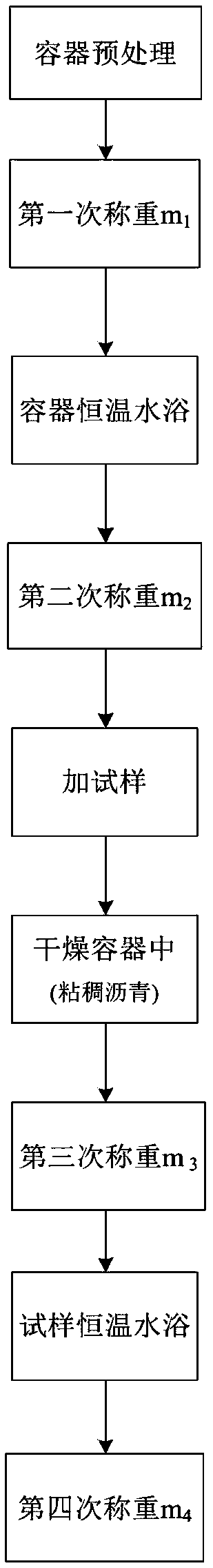

[0077] Example 1 Method for measuring viscous asphalt density and relative density based on weighing method at 15°C+0.1°C

[0078] 2.1.1 Wash the sample basin with lotion and water, then clean it with anti-sticking agent, then dry it and weigh it (m 1 ), accurate to 0.1g (all weighings in this test are accurate to 0.1g), hereinafter referred to as t1 temperature is 15°C+0.1°C.

[0079] 2.1.2 Determination of water value in sample basin at t1 temperature

[0080] Completely immerse the sample pot including the cover in the constant temperature water tank (extensometer water tank) at the temperature of t1. After constant temperature for 1 hour, take out and wipe off the surface water, and weigh the total mass of the sample basin, water and glass plate at this temperature (m 2 ).

[0081] Then at temperature t1, the water value in the sample basin is m 2 -m 1;

[0082] 2.1.3 Sample preparation, prepare viscous asphalt samples according to the T0602 method in JTGE20-2011 "Te...

Embodiment 2

[0086] Example 2 Method for measuring viscous asphalt density and relative density based on weighing method at 25°C+0.1°C

[0087] 2.1.1 Wash the sample basin with lotion and water, then clean it with anti-sticking agent, then dry it and weigh it (m 1 ), accurate to 0.1g.

[0088] Hereinafter referred to as t1 temperature is 25°C+0.1°C.

[0089] 2.1.2 Determination of water value in sample basin at t1 temperature

[0090] Completely immerse the sample pot including the cover in a constant temperature water bath (extensometer water tank) at temperature t1. After constant temperature for 1 hour, take it out and fill it with water, cover it with a glass plate, wipe off the surface water, and weigh the sample pot and water at this temperature. , the total mass of the glass plate (m 2 ).

[0091] Then at temperature t1, the water value in the sample basin is m 2 -m 1 ;

[0092] 2.1.3 Sample preparation, prepare viscous asphalt samples according to the T0602 method in JTGE20-...

Embodiment 3

[0096] Example 3 Method for Determination of Solid Asphalt Density and Relative Density Based on Gravimetric Method at 15°C+0.1°C

[0097] 2.3.1 Wash the sample basin with lotion and water, then clean it with anti-sticking agent, then dry it and weigh it (m 1 ), accurate to 0.1g, hereinafter referred to as t1 temperature is 15℃+0.1℃;

[0098] 2.3.2 Determination of water value in sample basin at temperature t1

[0099] Completely immerse the sample pot including the cover in a constant temperature water bath (extensometer water tank) at t1 temperature. After constant temperature for 1 hour, take out the cover and cover with a glass plate, wipe off the surface water, and weigh the total of the sample pot, water and glass plate at the temperature respectively. Mass (m 2 ), accurate to 0.1g;

[0100] Then at temperature t1, the water value in the sample basin is m 2 -m 1 ;

[0101] 2.3.3 Before the test, if the sample is wet, it can be dried naturally in a dry and clean env...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com