Iodine disinfection liquid and preparation method thereof

A technology of disinfectant and mixed solution, applied in the fields of botanical equipment and methods, disinfectants, chemicals for biological control, etc., can solve the problems of backward equipment manufacturing technology, immature process, and insufficient stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

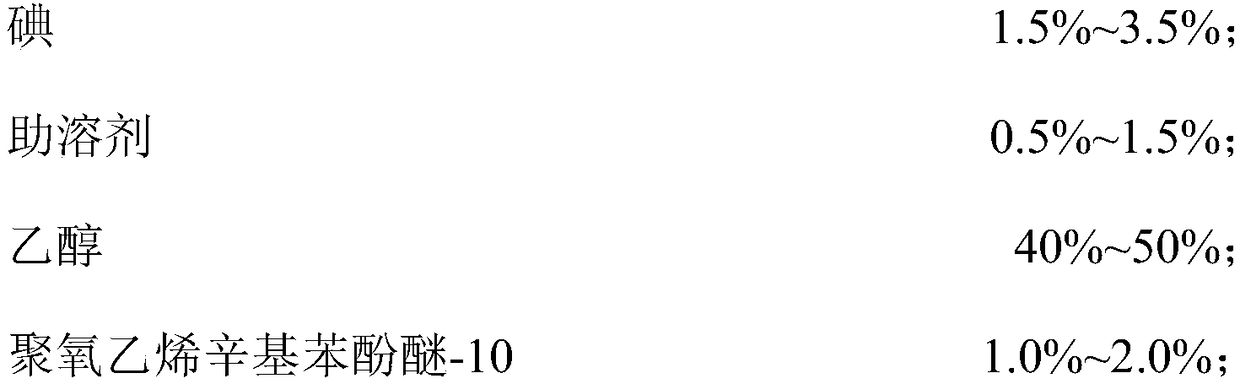

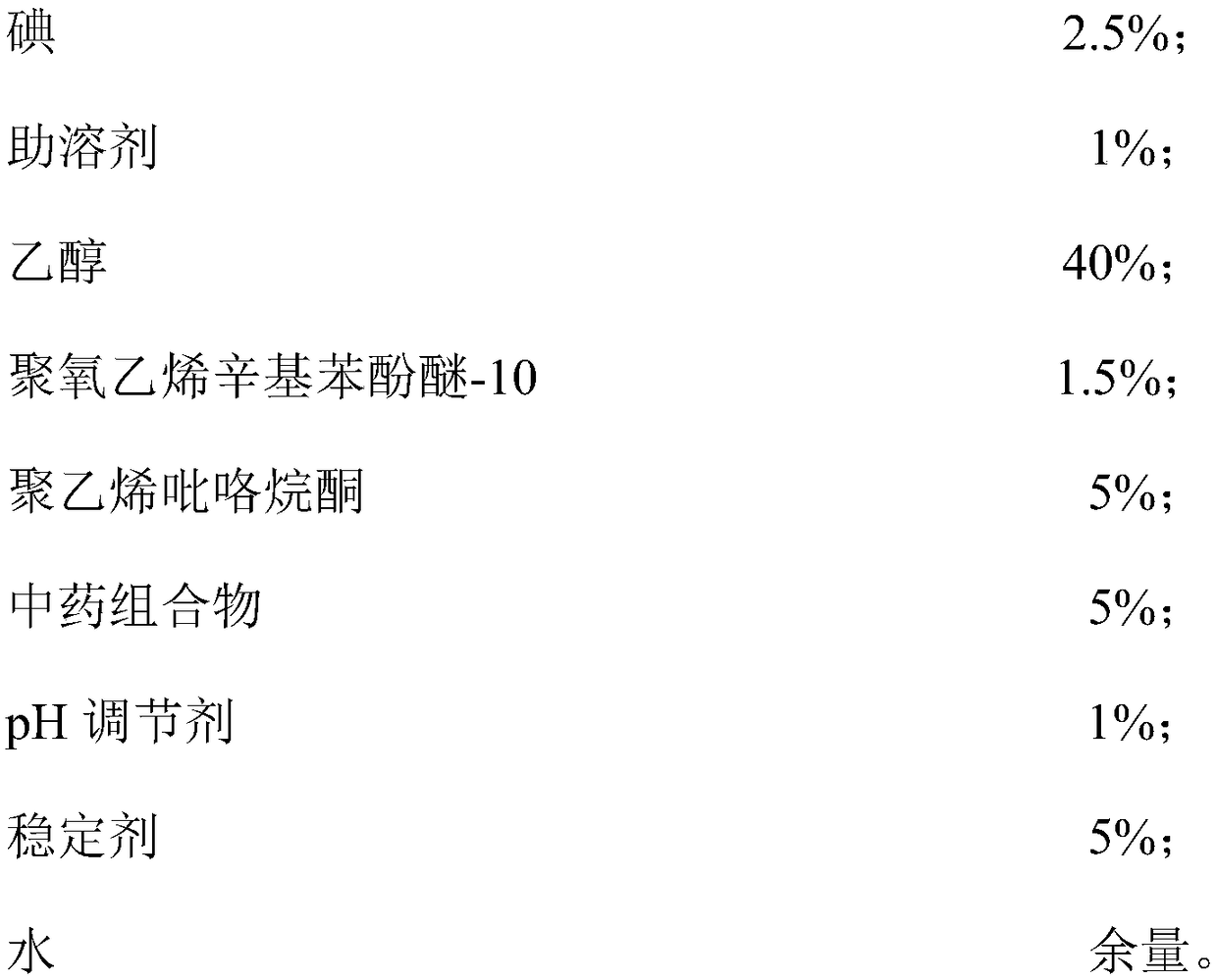

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the iodine disinfectant solution of one embodiment, comprises the following steps S110~S140:

[0043] S110, providing a traditional Chinese medicine composition.

[0044] Specifically, honeysuckle, forsythia and dandelion are mixed in proportion, sterilized and dried, soaked in aqueous ethanol solution, distilled, and the distillate is collected to obtain the traditional Chinese medicine composition.

[0045] Wherein, the volume ratio of ethanol and water in the ethanol aqueous solution is 1:1. The mass of ethanol aqueous solution is about 20 times of the total mass of honeysuckle, forsythia and dandelion.

[0046] S120, mixing polyoxyethylene octylphenol ether-10, polyvinylpyrrolidone, a stabilizer and an appropriate amount of water to obtain a first mixed liquid.

[0047] Mix OP-10, PVP, stabilizer and appropriate amount of water to form a stable solution system.

[0048] S130. Dissolving the co-solvent in the above-mentioned first mixed s...

Embodiment 1

[0062] Formula: 1.5g of iodine, 0.5g of KI, 40g of ethanol, 1.0g of OP-10, 4.5g of PVP, 4.0g of Chinese medicine composition (ethanol extract of dandelion, forsythia and honeysuckle), 0.5g of lemon potassium nitrate, 4.5 g of glycerin and 42.5 g of deionized water.

[0063] Preparation method: Mix OP-10, PVP, glycerin and an appropriate amount of deionized water, stir evenly, add KI, stir until dissolved, then add iodine, stir evenly, then add Chinese medicine composition, stir for 1 hour, and keep it standing at 40°C After 3 hours, cool to room temperature, add potassium citrate, stir evenly, add deionized water to constant volume, and obtain an iodine disinfectant with a pH value of 6.

Embodiment 2

[0065] Formula: 3.5g of iodine, 1.5g of KI, 50g of ethanol, 2.0g of OP-10, 5.5g of PVP, 6.0g of Chinese medicine composition (ethanol extract of dandelion, forsythia and honeysuckle), 1.5g of lemon potassium nitrate, 5.5 g of glycerin and 24.5 g of deionized water.

[0066] Preparation method: Mix OP-10, PVP, glycerin and an appropriate amount of deionized water, stir evenly, add KI, stir until dissolved, then add iodine, stir evenly, then add Chinese medicine composition, stir for 1 hour, and keep it standing at 40°C After 3 hours, cool to room temperature, add potassium citrate, stir evenly, add deionized water to constant volume, and obtain an iodine disinfectant with a pH value of 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com