Long-acting mildew-proof processing method for bamboos

A processing method, bamboo technology, applied in wood processing equipment, wood treatment, impregnated wood, etc., can solve the problems of poor dispersion ability of inorganic nanoparticles, many reaction steps, unfriendly environment, etc., to overcome poor adhesion, easy Effect of operation, long-lasting antimicrobial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

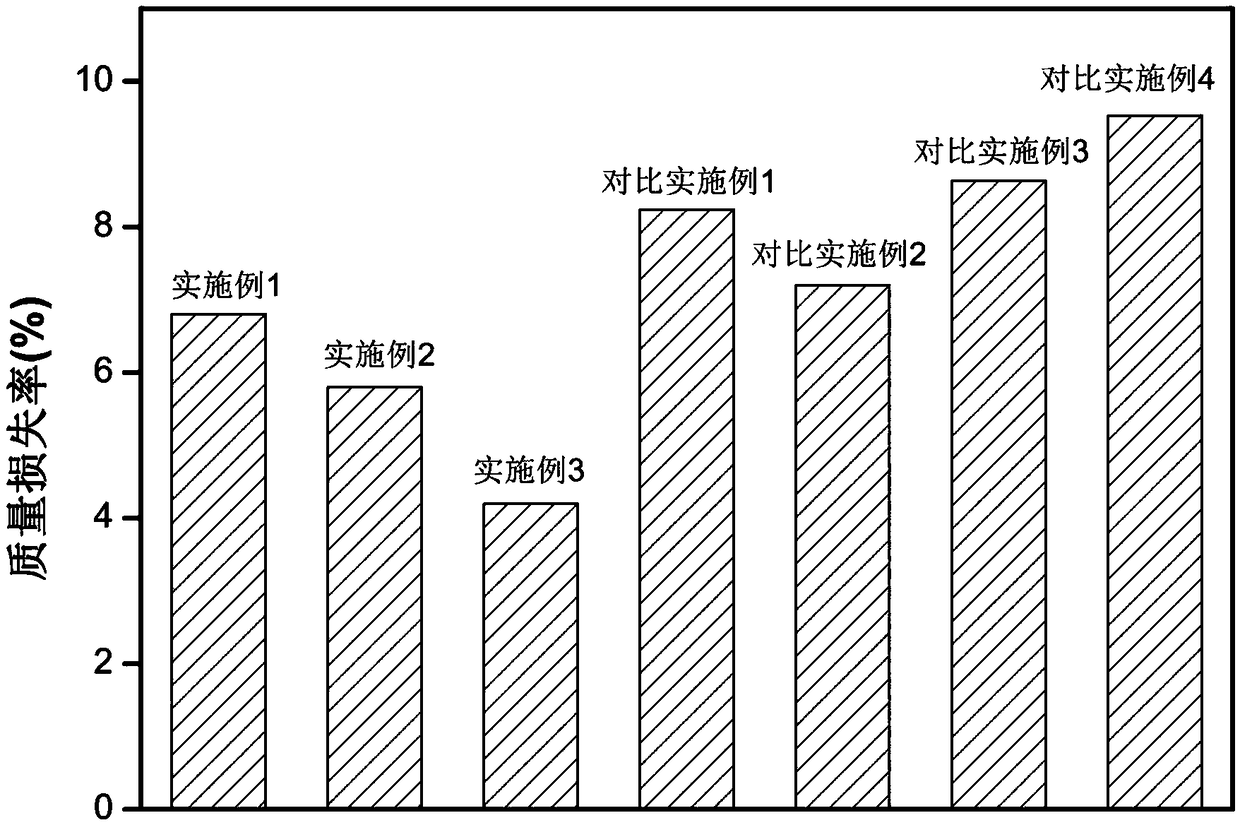

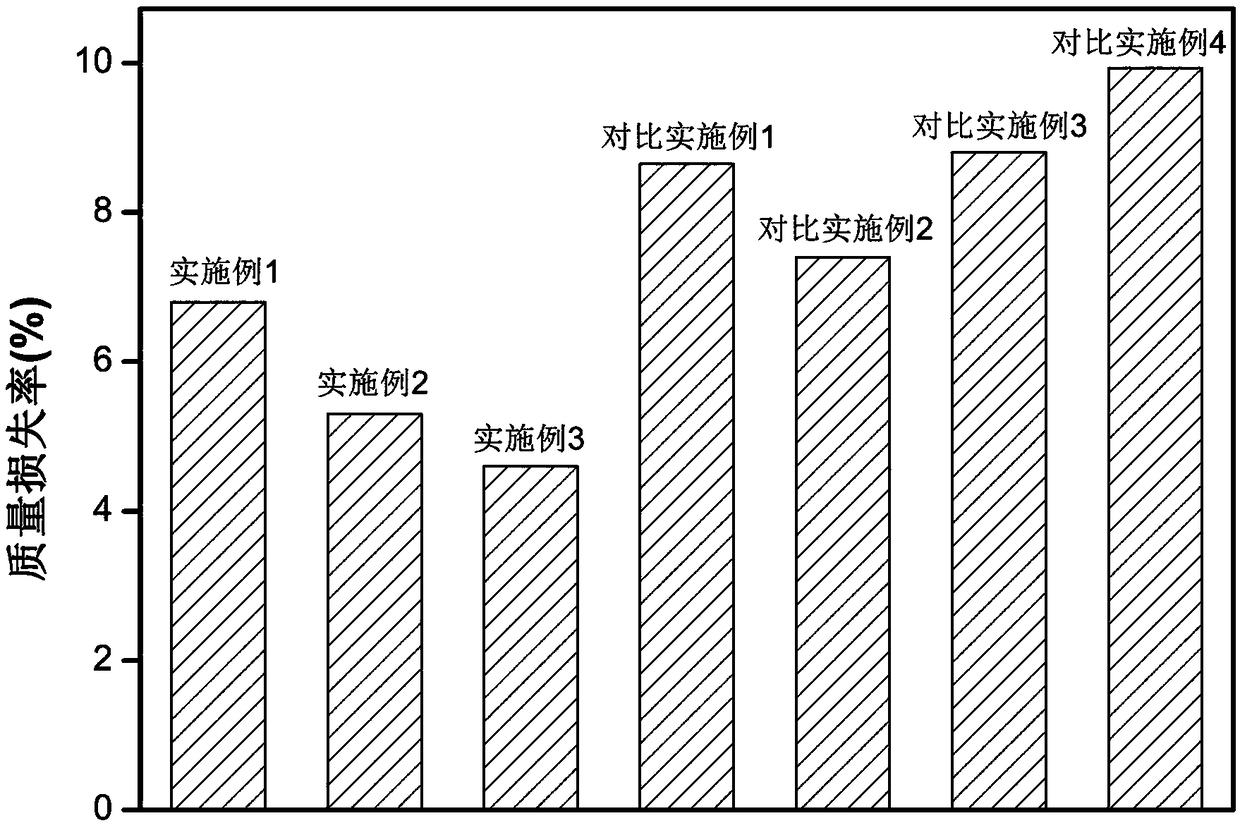

Embodiment 1

[0033] (1) Bamboo drying: Take moso bamboo as an example, first process it into bamboo blocks with a thickness of 20mm*20mm*6mm, and dry the bamboo until the moisture content is below 5%;

[0034] (2) Preparation of nanoparticles: Disperse 0.6g of cetyltrimethylammonium bromide and 1.8mL (2mol / L) NaOH solution in 300mL deionized water, and add 1.8mL (1mol / L) formaldehyde solution to heat Stir for 5-20min, then dropwise add 6mL of AgNO 3 (0.1 mol / L) solution, 3.2 mL of tetraethyl orthosilicate and 12 mL of ethyl acetate, aged at 80°C for 2 hours, centrifuged, washed repeatedly, and dried for later use;

[0035] (3) Nanoparticles are miscible in oil: 1 g of core-shell SiO 2 The @Ag nanoparticles were added to 100g of tung oil, and the ball mill was stirred at a speed of 400rpm for 5h by the physical method of a planetary ball mill;

[0036] (4) Impregnation treatment: the bamboo is completely immersed in SiO 2 In the mixed solution of @Ag-tung oil, under normal temperature en...

Embodiment 2

[0040] (1) Bamboo drying: Take moso bamboo as an example, first process it into bamboo blocks with a thickness of 20mm*20mm*6mm, and dry the bamboo until the moisture content is below 5%;

[0041] (2) Preparation of nanoparticles: Disperse 0.6g of cetyltrimethylammonium bromide and 1.8mL (2mol / L) NaOH solution in 300mL deionized water, and add 1.8mL (1mol / L) formaldehyde solution to heat Stir for 5-20min, then dropwise add 6mL of AgNO 3 (0.1 mol / L) solution, 3.2 mL of tetraethyl orthosilicate and 12 mL of ethyl acetate, aged at 80°C for 2 hours, centrifuged, washed repeatedly, and dried for later use;

[0042] (3) Nanoparticles are miscible in oil: 5g core-shell SiO 2 The @Ag nanoparticles were added to 100g of tung oil, and the ball mill was stirred at a speed of 400rpm for 5h by the physical method of a planetary ball mill;

[0043] (4) Impregnation treatment: the bamboo is completely immersed in SiO 2 In the mixed solution of @Ag-tung oil, under normal temperature enviro...

Embodiment 3

[0047] (1) Bamboo drying: Take moso bamboo as an example, first process it into bamboo blocks with a thickness of 20mm*20mm*6mm, and dry the bamboo until the moisture content is below 5%;

[0048] (2) Preparation of nanoparticles: Disperse 0.6g of cetyltrimethylammonium bromide and 1.8mL (2mol / L) NaOH solution in 300mL deionized water, and add 1.8mL (1mol / L) formaldehyde solution to heat Stir for 5-20min, then dropwise add 6mL of AgNO 3 (0.1 mol / L) solution, 3.2 mL of tetraethyl orthosilicate and 12 mL of ethyl acetate, aged at 80°C for 2 hours, centrifuged, washed repeatedly, and dried for later use;

[0049] (3) Nanoparticles are miscible in oil: 10g core-shell SiO 2 The @Ag nanoparticles were added to 100g of tung oil, and the ball mill was stirred at a speed of 400rpm for 5h by the physical method of a planetary ball mill;

[0050] (4) Impregnation treatment: the bamboo is completely immersed in SiO 2 In the mixed solution of @Ag-tung oil, under normal temperature envir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com