Multifunctional composite decorative material

A technology of decorative materials and calendered materials, which is applied in the field of multifunctional composite decorative materials, can solve problems such as insufficient versatility, single functionality of wallpaper, wall covering or decorative panels, etc., and achieve convenient printing, good decorative effects, and visually pleasing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

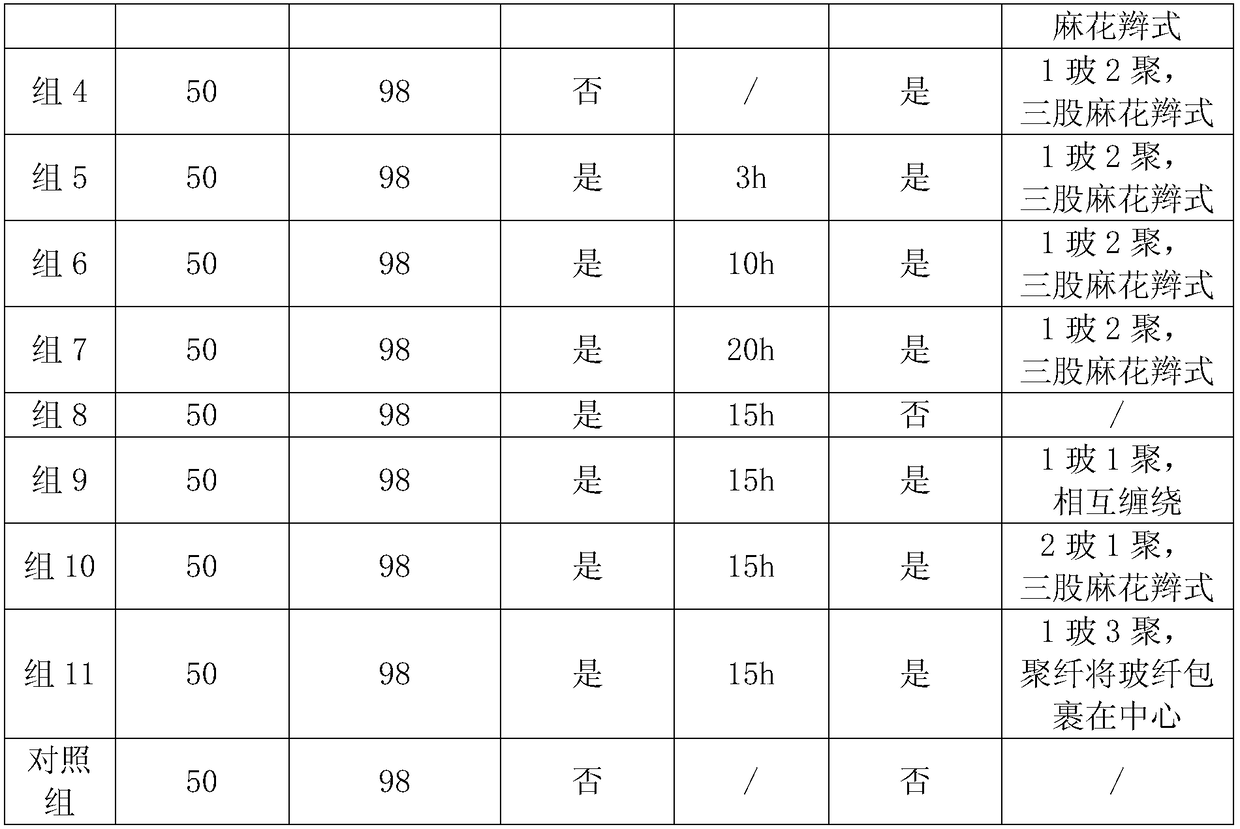

[0052] Example 1: Effect display of different fiber treatment methods

[0053] 1. Prepare 11 sets of composite decorative materials according to the above formula and operation steps. The rest of the conditions are the same, no toughening treatment and weaving treatment are used as the control group.

[0054] The parts by weight of glass fiber and polyimide fiber in each group, the treatment method, and the nonwoven fabric preparation method are shown in Table 1. Wherein, the fiber bundles are not woven, which refers to directly mixing glass fibers and polyimide fibers and then combing them into a web to prepare a non-woven fabric. In the fiber bundle weaving method, "glass" / "glass fiber" is used instead of glass fiber, and "poly" / "polyfiber" is used instead of polyimide fiber. The numbers in front of "glass" and "poly" refer to a bundle of fibers respectively. In the bundle, the number of glass fibers and polyimide fibers respectively; for example, 1 glass 2 poly refers to ...

Embodiment 2

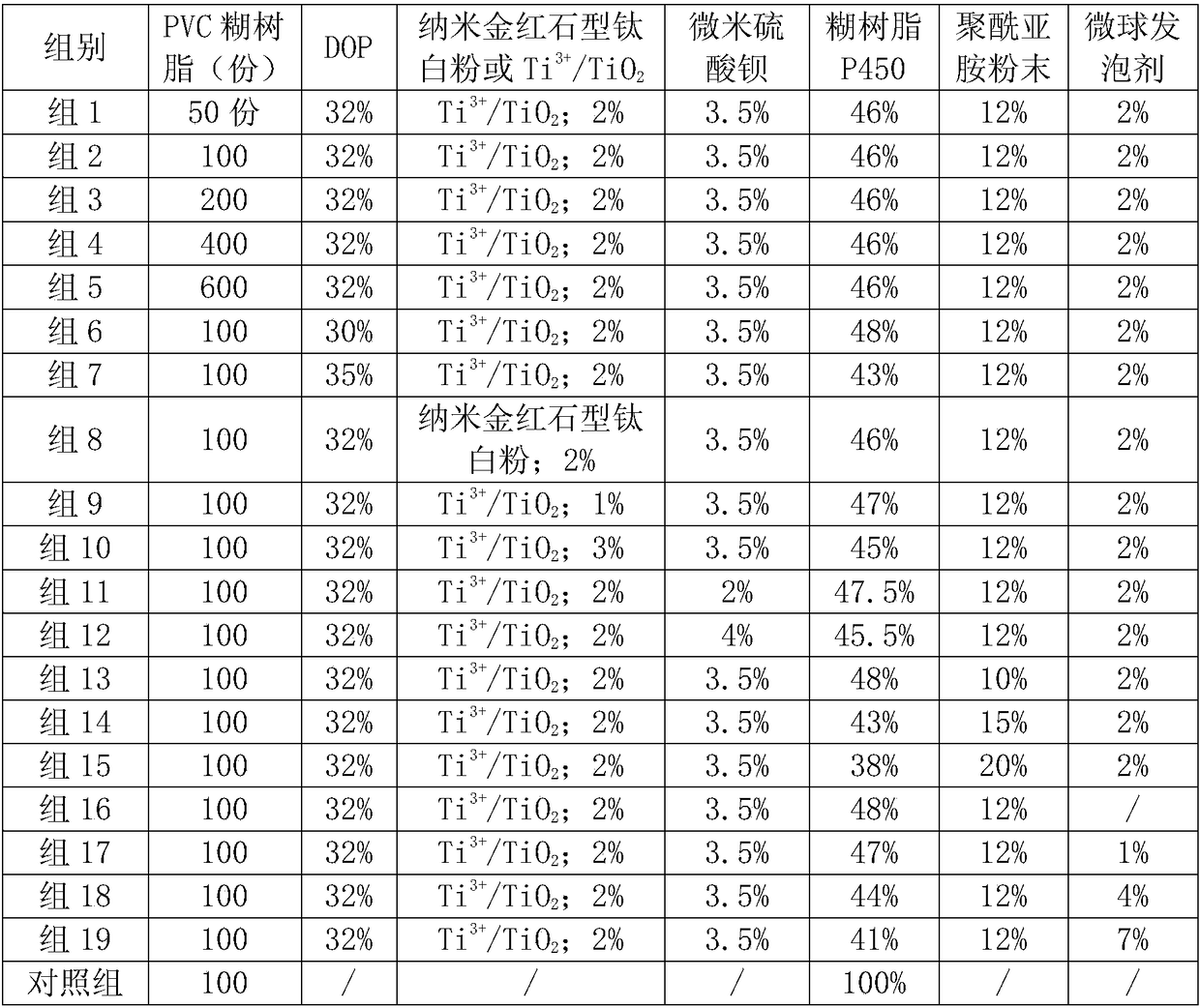

[0061] Example 2: Effect display of different PVC paste resin treatment methods

[0062] 1. Use the non-woven fabric prepared in Group 2 in Example 1 as the base layer to prepare 19 groups of composite decorative materials. Wherein, the total formula is: in parts by weight, 50 parts of calendering material and 0.3 part of ultra-thin carbon nanotube coating material; the calendering material is PU calendering leather.

[0063] The formula, processing method and parts by weight of PVC paste resin in each group are as shown in Table 3. The PVC paste resin in the table refers to the parts by weight of the PVC paste resin in the total formula, and each component in the PVC paste resin formula refers to the mass percentage of each component in the PVC paste resin formula. Among them, any barium-zinc heat stabilizer that can be used for PVC products and has good compatibility with resins can be used. For the sake of convenience, the barium-zinc heat stabilizers used in the whole tex...

Embodiment 3

[0086] Embodiment 3: The effect demonstration of different total formulations

[0087] 1. Prepare 7 groups of composite decorative materials according to the method of Example 2, Group 2, wherein the formula components of each group are shown in Table 7. The parts by weight of the calendering material in the table represent its share in the total formula, and the ratio of the calendering material to the carbon nanotube coating material refers to the weight ratio of the two (the corresponding carbon nanotube coating material parts by weight are 0.1 parts ~ 1.2 parts). The non-sprayed carbon nanotube coating material was used as the control group.

[0088] The formula component list of each group of table 7

[0089] group

Calendered material

Calendering material: carbon nanotube coating material

group 1

50 copies

1000:6

group 2

100 copies

1000:6

group 3

150 copies

1000:6

group 4

200 copies

1000:6

G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com