Compound bag for packaging drugs and preparation method thereof

A composite bag and packaging technology, applied in the field of pharmaceutical packaging materials, can solve the problems of unsatisfactory moisture barrier, gas barrier, thermal insulation performance, poor barrier performance, poor stability, etc., and achieve broad drug compatibility , to ensure the effect of good barrier performance and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A composite bag for pharmaceutical packaging and a preparation method thereof:

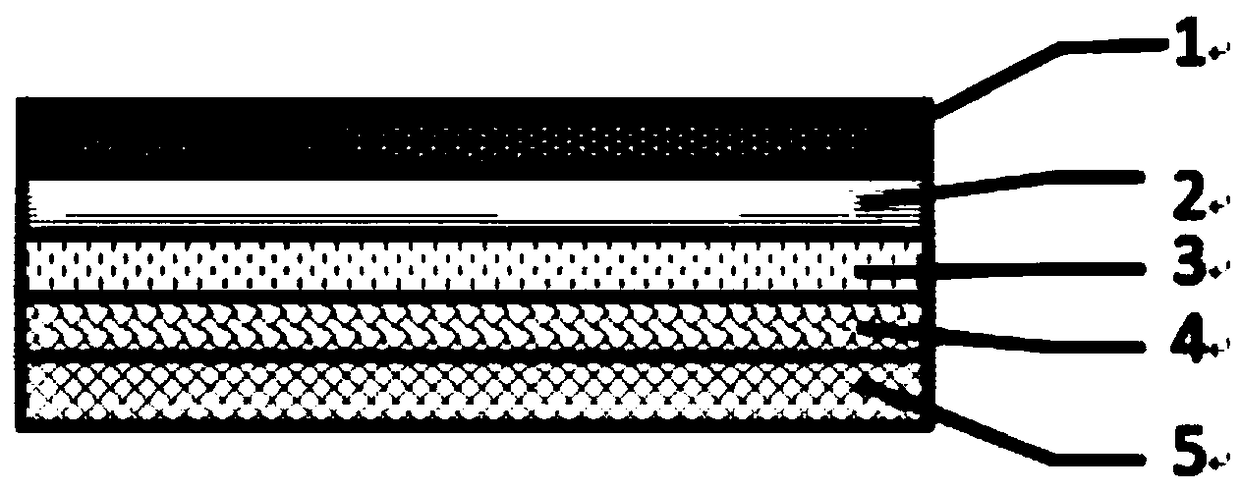

[0021] A composite bag for pharmaceutical packaging, comprising: a heat-sealing layer 1, a barrier layer 2, an aluminum foil layer 3, an adhesive layer 4, and a weather-resistant layer 5; the heat-sealing layer is composed of high melting point metallocene polypropylene and ethylene-octene Copolymer; the composition of the barrier layer is medical or food grade polyvinylidene chloride and oxidized polyethylene; the composition of the aluminum foil layer is aluminum foil; the composition of the adhesive layer is maleic anhydride modified polypropylene and nano silicon dioxide Airgel particles; the weather-resistant layer is composed of low-density polyethylene film.

[0022] The nano-silica airgel particle is a light-weight nano-solid material composed of nano-scale ultrafine particles aggregated to form a nano-porous network structure, and the network pores are filled with a gaseous dispers...

Embodiment 2

[0028] A composite bag for pharmaceutical packaging and a preparation method thereof:

[0029] A composite bag for pharmaceutical packaging, comprising: a heat-sealing layer 1, a barrier layer 2, an aluminum foil layer 3, an adhesive layer 4, and a weather-resistant layer 5; the heat-sealing layer is composed of high melting point metallocene polypropylene and ethylene-octene Copolymer; the composition of the barrier layer is medical or food grade polyvinylidene chloride and oxidized polyethylene; the composition of the aluminum foil layer is aluminum foil; the composition of the adhesive layer is maleic anhydride modified polypropylene and nano silicon dioxide Airgel particles; the weather-resistant layer is composed of low-density polyethylene film.

[0030] The nano-silica airgel particle is a light-weight nano-solid material composed of nano-scale ultrafine particles aggregated to form a nano-porous network structure, and the network pores are filled with a gaseous dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com