M25 common dry-powder plastering mortar and preparation and use method thereof

A technology for plastering mortar and dry powder, applied in the field of mortar, can solve problems such as shortage of resources, and achieve the effects of preventing segregation and stratification, improving performance stability, and improving cohesion and water retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

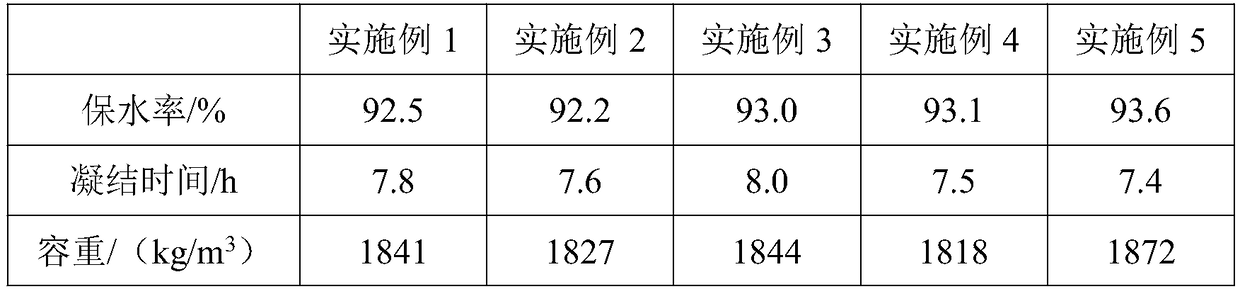

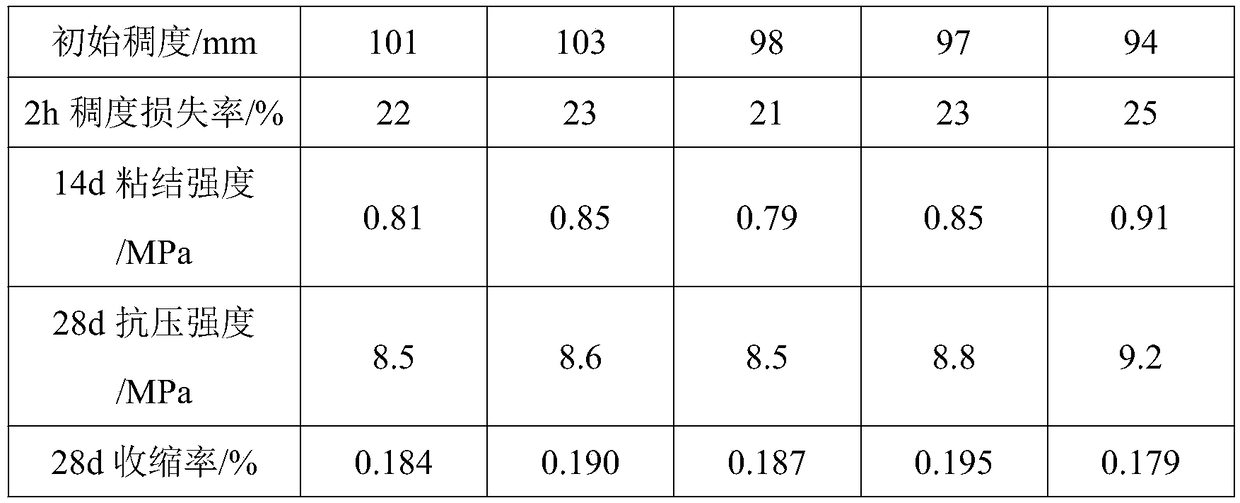

Embodiment 1

[0033] An M5 ordinary dry powder plastering mortar, consisting of the following materials: 90 parts of cement, 45 parts of sulfur-fixed ash, 65 parts of alkali slag, 800 parts of fine aggregate, 4 parts of redispersible latex powder, 0.17 parts of water-retaining agent, defoaming 0.12 part of agent, 0.9 part of water reducer, in parts by weight.

[0034] The cement is selected from P.O 42.5 cement, provided by Dujiangyan Lafarge Cement Co., Ltd., and its performance test results are as follows: standard consistency water demand 26.7%, specific surface area 369m 2 kg -1 , initial setting time 170min, final setting time 246min, 3-day flexural strength 6.0MPa, 28-day flexural strength 8.3MPa, 3-day compressive strength 31.2MPa, 28-day compressive strength 50.1MPa, SO 3 The content is 2.03% (≤3.5%), the MgO content is 2.41% (≤5%), and the stability is qualified.

[0035] The sulfur-fixed ash is selected from the treated sulfur-fixed ash, and the undisturbed sulfur-fixed ash is p...

Embodiment 2

[0045] An M5 ordinary dry powder plastering mortar, consisting of the following materials: 95 parts of cement, 40 parts of sulfur-fixed ash, 65 parts of alkali slag, 800 parts of fine aggregate, 4 parts of redispersible latex powder, 0.17 parts of water-retaining agent, defoaming 0.12 part of agent, 0.9 part of water reducer, in parts by weight.

[0046] The cement is selected from P.O 42.5 cement, provided by Dujiangyan Lafarge Cement Co., Ltd., and its performance test results are as follows: standard consistency water demand 26.7%, specific surface area 369m 2 kg -1 , initial setting time 170min, final setting time 246min, 3-day flexural strength 6.0MPa, 28-day flexural strength 8.3MPa, 3-day compressive strength 31.2MPa, 28-day compressive strength 50.1MPa, SO 3 The content is 2.03% (≤3.5%), the MgO content is 2.41% (≤5%), and the stability is qualified.

[0047] The sulfur-fixed ash is selected from the treated sulfur-fixed ash, and the undisturbed sulfur-fixed ash is p...

Embodiment 3

[0057] An M5 ordinary dry powder plastering mortar, consisting of the following materials: 85 parts of cement, 45 parts of sulfur-fixed ash, 70 parts of alkali slag, 800 parts of fine aggregate, 4 parts of redispersible latex powder, 0.17 parts of water-retaining agent, defoaming 0.12 part of agent, 0.9 part of water reducer, in parts by weight.

[0058] The cement is selected from P.O 42.5 cement, provided by Dujiangyan Lafarge Cement Co., Ltd., and its performance test results are as follows: standard consistency water demand 26.7%, specific surface area 369m 2 kg -1 , initial setting time 170min, final setting time 246min, 3-day flexural strength 6.0MPa, 28-day flexural strength 8.3MPa, 3-day compressive strength 31.2MPa, 28-day compressive strength 50.1MPa, SO 3 The content is 2.03% (≤3.5%), the MgO content is 2.41% (≤5%), and the stability is qualified.

[0059] The sulfur-fixed ash is selected from the treated sulfur-fixed ash, and the undisturbed sulfur-fixed ash is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com