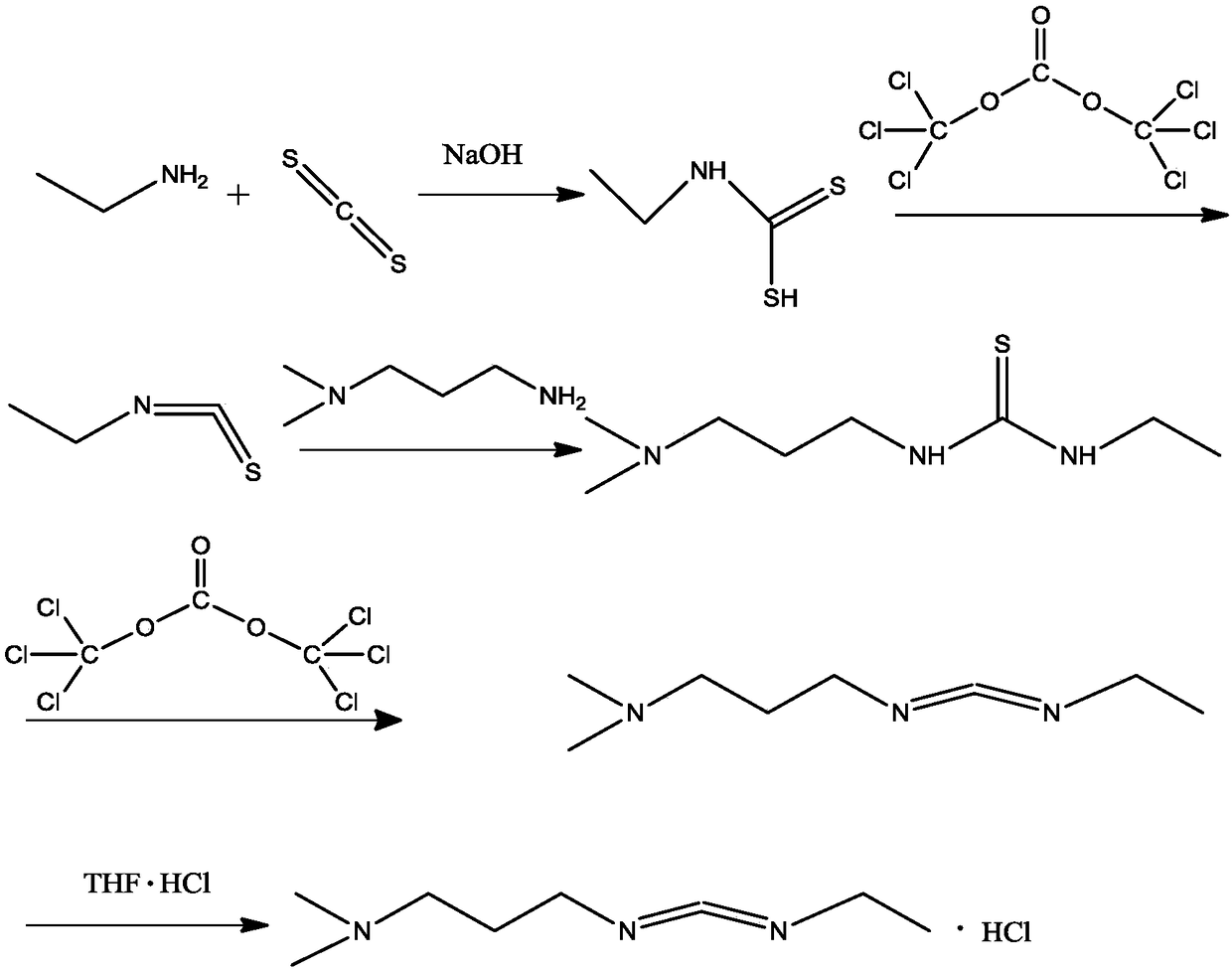

Preparation method of 1-ethyl-(3-dimethyl amino propyl) carbodiimide hydrochloride

A technology of dimethylaminopropyl and carbodiimide hydrochloride, which is applied in the direction of organic chemistry, can solve the problems of cumbersome steps, complicated operation, and unsuitability for industrial production, and achieve simplified operation steps, high purity, and easy The effect of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0036] Add 195g of carbon disulfide and 198g of 40% mass concentration liquid caustic soda into a 2000ml reaction bottle, slowly add 143g of ethylamine dropwise, keep the temperature at 25°C, add dropwise for 60min, stir and keep warm for 90min, and react to generate EDTC; Dissolve 172g of the ester in 240g of cyclohexane, slowly drop it into the EDTC reaction solution, keep the temperature at 20°C, add the mixture for 90 minutes, and keep it warm for 150 minutes.

[0037] Transfer the material to an oil bath for distillation. Distill at an oil bath temperature of about 120°C until nothing comes out. Take the fraction and separate it in a separatory funnel. The upper layer of oil is EITC. 197g of the product is obtained with a yield of 89% and a purity of >99% %.

[0038] Add 600g of water to a 2000ml reaction bottle, add 273g of N,N-dimethyl-1,3-propanediamine, slowly add 197g of EITC dropwise, keep the temperature at 18°C, complete the dropwise addition in 60min, keep warm f...

Embodiment 3

[0041] Add 200g of carbon disulfide and 240g of 40% mass concentration liquid caustic soda into a 2000ml reaction bottle, slowly drop into 167g of ethylamine, keep the temperature at 15°C, add the time for 30min, stir and keep warm for 90min, and react to generate EDTC; Dissolve 149g of ester in 280g of petroleum ether, slowly drop into the EDTC reaction solution, keep the temperature at 27°C, add for 90min, and keep warm for 120min.

[0042] Transfer the material to an oil bath for distillation. Distill at an oil bath temperature of about 130°C until nothing comes out. Take the fraction and separate it in a separatory funnel. The upper layer of oil is EITC. 200g of the product is obtained with a yield of 90% and a purity of >99% %.

[0043] Add 600g of water to a 2000ml reaction bottle, add 300g of N,N-dimethyl-1,3-propanediamine, slowly add 200g of EITC dropwise, keep the temperature at 26°C, complete the dropwise addition in 30 minutes, and keep it warm for 120 minutes to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com