Preparation process of silicate reverse osmosis scale inhibitor

A preparation process and reverse osmosis technology, which is applied in the new process field of water medium scale inhibitor, can solve the problems of dangerous operation, high toxicity of hydrofluoric acid, high cost of membrane replacement, etc., and achieve non-severe temperature rise, easy control, and high tolerance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

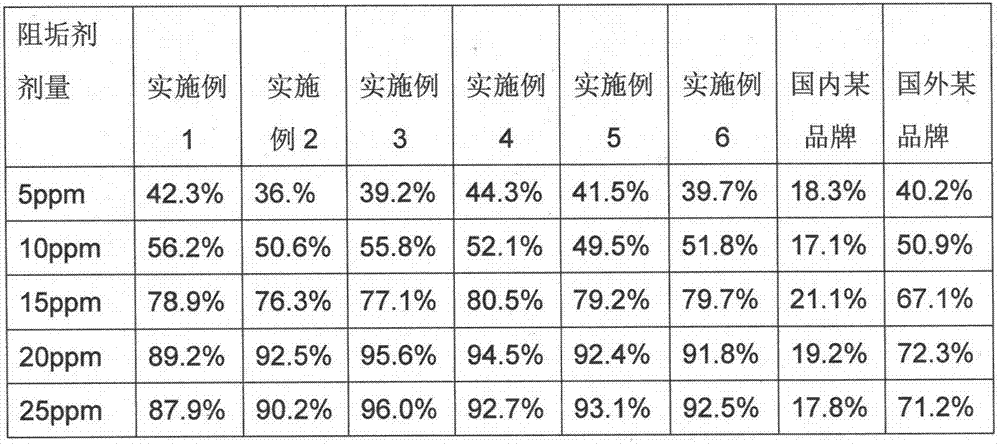

Examples

Embodiment 1

[0020] A preparation process of a silicate reverse osmosis scale inhibitor, the specific steps are: dissolving 98 kilograms of maleic anhydride in 40 kilograms of water, adding 80 kilograms of 50% sodium hydroxide solution dropwise under stirring, and controlling the reaction temperature to 20 ~50°C to convert maleic anhydride into maleic acid sodium salt; after reacting for 0.5h, heat the reaction system to 50~60°C in a water bath of 60~65°C, and add 127 kg of 30% hydrogen peroxide in five times , every interval of 20 minutes; add 12.19 kg of catalyst vanadium pentoxide, carry out the epoxidation reaction of maleate to generate sodium epoxy succinate, control the reaction temperature at 65-70°C, pH value of 5-7, heat preservation reaction After 1.5 hours, 16 kg of diethylenetriamine was added to carry out the polymerization reaction. The reaction temperature was controlled at 85-90°C and the reaction time was 4 hours to obtain a brownish-red viscous liquid with a solid content...

Embodiment 2

[0022] A kind of preparation technology of silicate reverse osmosis antiscaling agent, concrete steps are: dissolve 196 kilograms of maleic anhydride in 100 kilograms of water, slowly add 165 kilograms of 50% sodium hydroxide solution under the condition of stirring, control reaction temperature 40 ~50°C to convert maleic anhydride into maleic acid sodium salt; after reacting for 0.5h, heat the reaction system to 50~60°C in a water bath of 60~65°C, add 200 kg of 30% hydrogen peroxide in six times , every interval of 20 minutes; add 15.19 kg of catalyst vanadium pentoxide, carry out epoxidation reaction of maleate to generate sodium epoxy succinate, control the reaction temperature at 65-70 ° C, pH value of 5.5-6.0, heat preservation reaction After 1 hour, 19 kg of diethylenetriamine was added to carry out the polymerization reaction, the reaction temperature was controlled at 90-100°C, and the reaction time was 3.5 hours to obtain a brown-red viscous liquid with a solid content...

Embodiment 3

[0024] A kind of preparation technology of silicate reverse osmosis antiscalant, concrete steps are: dissolve 294 kilograms of maleic anhydride in 110 kilograms of water, slowly add 300 kilograms of 40% sodium hydroxide solution under the condition of stirring, control reaction temperature 20 ~30 ℃, maleic anhydride is converted into maleic acid sodium salt; after reacting for 0.5 hours, the reaction system is heated to 55~60 ℃ in a water bath of 60~65 ℃, and 320 kg of 30% hydrogen peroxide is added in seven times, Each interval is 20 minutes; add 18.9 kg of catalyst vanadium pentoxide to carry out epoxidation reaction of maleate to generate sodium epoxy succinate, control the reaction temperature at 65-70°C, pH value at 5.5-6.0, and keep warm for 1 hour Finally, add 12 kg of diethylenetriamine to carry out the polymerization reaction, control the reaction temperature to 90-95°C, and the reaction time is 3 hours to obtain a brownish-red viscous liquid with a solid content of no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com