Method for preparing water-based paint of steel structure

A technology for water-based coatings and steel structures, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of affecting the anti-corrosion performance of coatings, the decrease of adhesion, and the decrease of barrier properties, so as to reduce VOC emissions and increase Adhesion, the effect of enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with specific examples.

[0023] (1) Purification of fulvic acid: put a certain amount of fulvic acid in a three-neck flask, add an appropriate amount of absolute ethanol, start the agitator, heat up to the liquid boiling, remove the liquid and filter, centrifuge the obtained filtrate, freeze-dry to obtain purified Fulvic acid (FA).

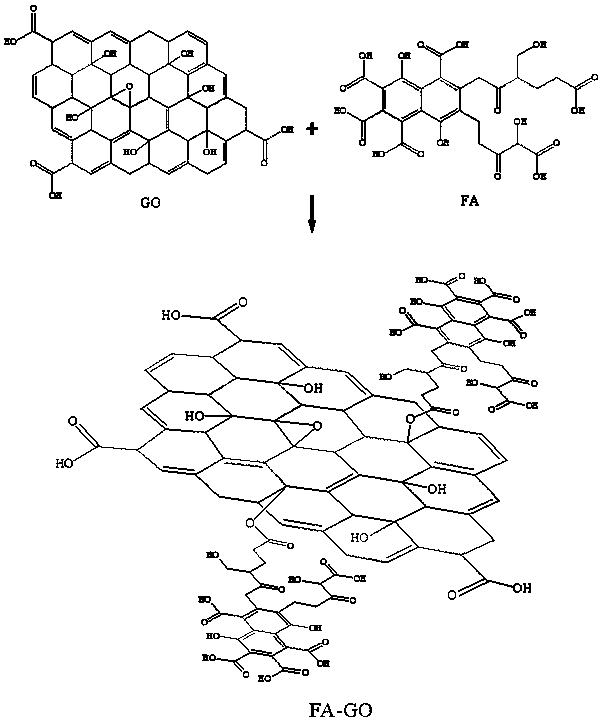

[0024] (2) Fulvic acid-modified graphene: put 100ml of reduced graphene suspension (1.0g) in a three-necked bottle, start the stirrer, and disperse for 0.5h. Slowly add the fulvic acid solution under low temperature stirring. After the fulvic acid solution is added dropwise, slowly raise the temperature to 30°C, continue to stir for an hour, and collect the sample by centrifugation; finally, put the collected sample in deionized water, continue to stir for 2 hours, and take out the reaction solution , washed three times with deionized water, centrifuged, and fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com