Design and preparing method of double-layer functional fabric

A design method and functional technology, applied in textiles, woven fabrics, fabrics, etc., to achieve the effects of good heat transfer performance, light and thin fabrics, and unique antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

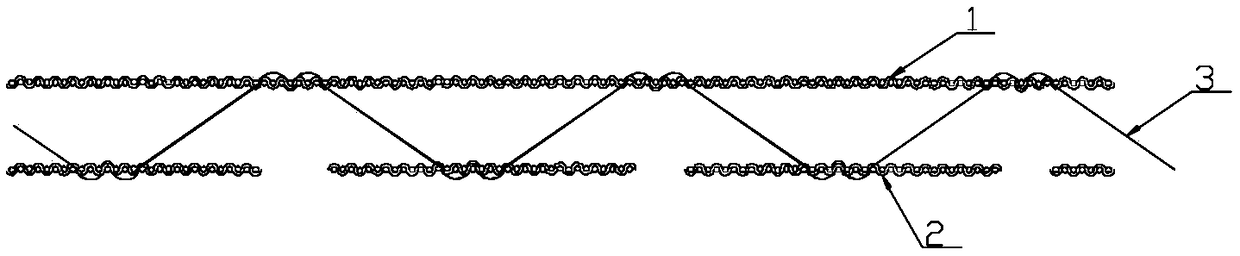

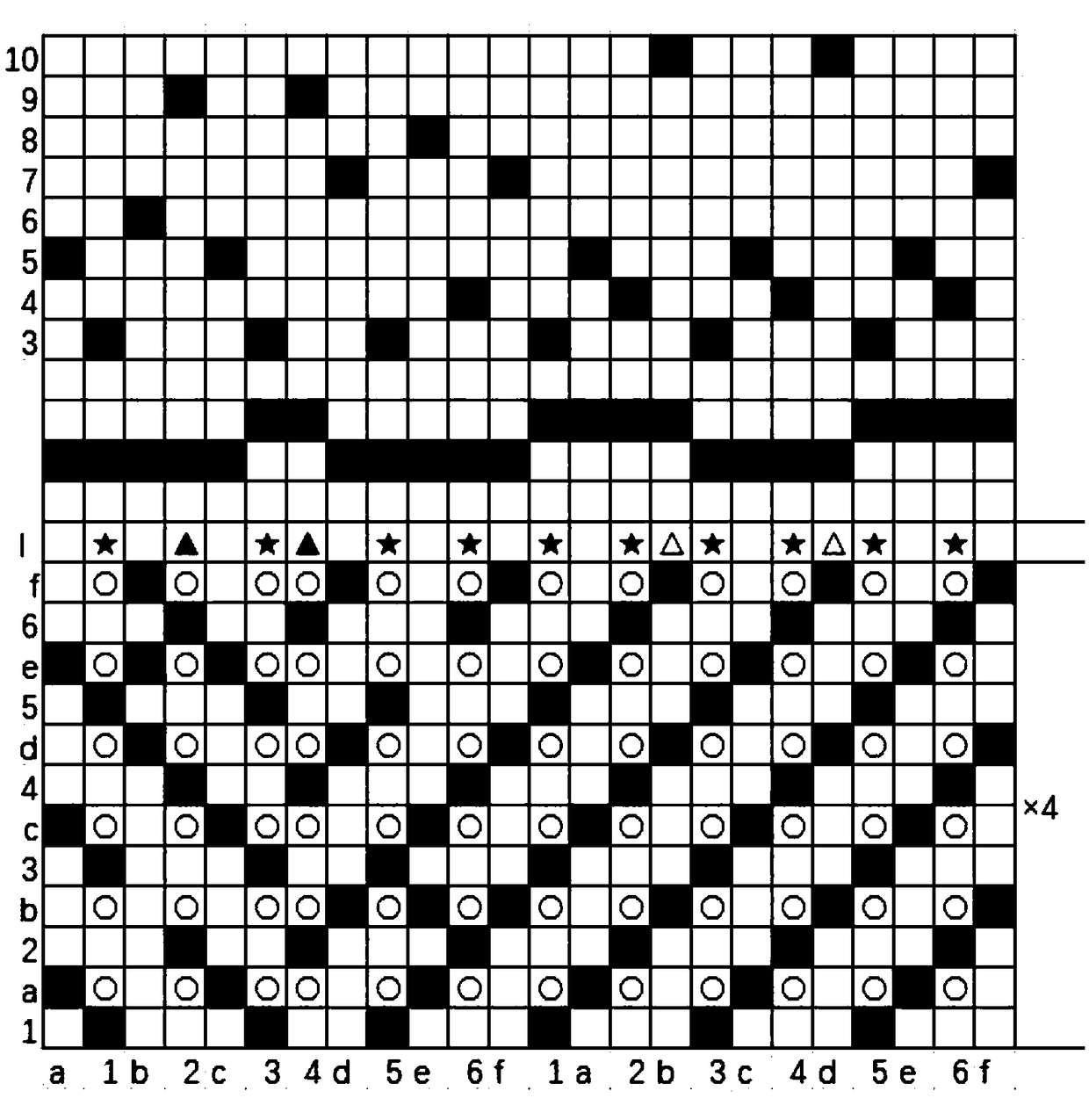

[0043] A design method for double-layer functional fabrics, such as figure 1 As shown, the double-layer functional fabric includes a surface layer 1, an inner layer 2, and a connecting yarn 3; wherein:

[0044] The surface layer is: soft, light and thin fabric, made of multicolored segment-dyed filaments of nylon fiber with anti-ultraviolet function, the specification of the filaments is 80D / 72F, and the weave design is plain weave;

[0045] The inner layer is: soft, light and thin fabric, with functions of moisture absorption, breathability, perspiration, antibacterial, and heat dissipation. The specification of graphene nylon filament is 40D / 24F, and the specification of colored viscose filament is 40D / 12F. Silk and viscose filaments are twisted together, and the weave design adopts through-hole weave;

[0046] The connecting yarn is: colored nylon filament, ATY30D / 12F.

[0047] ATY yarn was invented by DuPont in the United States. Air jet technology is used to interlace t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com