Preparation method for flexible high-atomic-number material TEM (transmission electron microscope) sample

A transmission electron microscope sample, high atomic number technology, applied in the use of wave/particle radiation for material analysis, material analysis, measuring devices, etc., can solve difficult problems, achieve area increase, prevent deformation, improve preparation accuracy and prepare finished products rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] According to an exemplary embodiment of the present invention, the method for preparing a TEM sample of a flexible high atomic number material mainly includes the following steps.

[0048] Step A:

[0049] The "H-bar Lift-out" process was used to place the thin slice sample taken from the preparation area of the bulk sample of the flexible high atomic number material on the copper grid column for TEM experiments.

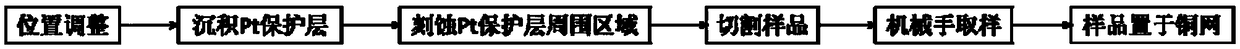

[0050] figure 1 It shows the overall flowchart of step A using the "H-bar Lift-out" process to place the thin slice sample taken from the preparation area of the bulk sample of flexible high atomic number material on the copper grid column for TEM experiment.

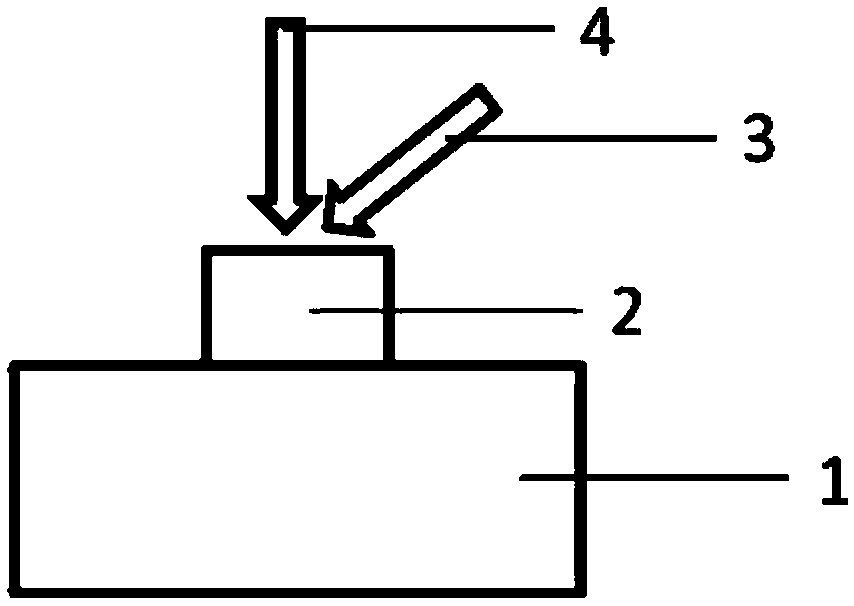

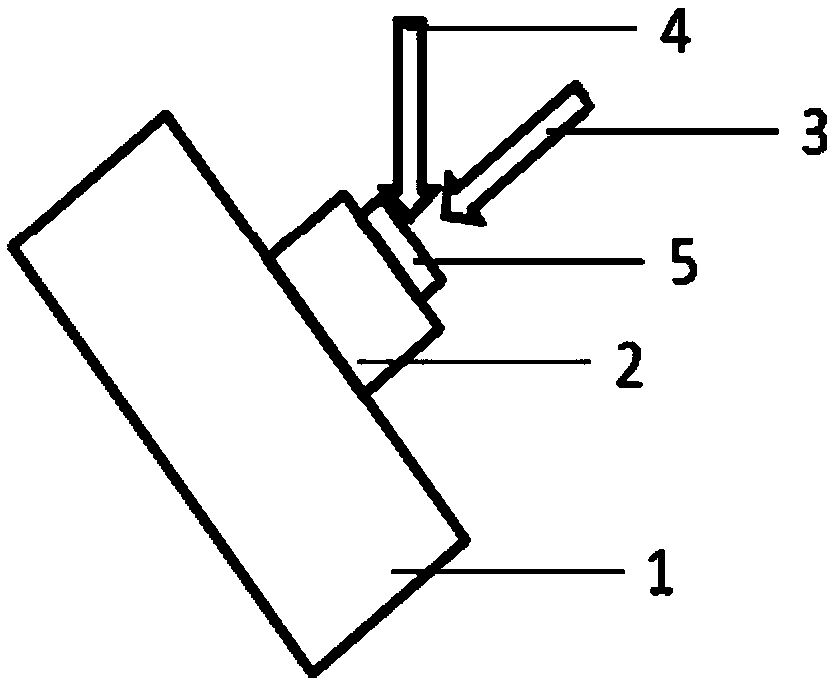

[0051] The "H-bar Lift-out" process is a commonly used sample preparation process. First, a layer of Pt or W is plated on the area of interest for protection, and then a thicker piece is cut out of the bulk sample by FIB. In the FIB sample cavity, the die is transferred to the copper grid, and ...

Embodiment 1

[0080] Figure 6a and Figure 6b Respectively show a top view structural schematic diagram and a side view structural schematic diagram of the Pt protective layer on the sample surface in Example 1, Figure 6c and Figure 6d Respectively show the Pt protective layer in Example 1 and the sample front view structure schematic diagram and side view structure schematic diagram under it, Figure 6e A schematic plan view of the structure of the sub-regional thinning of the sample by using the focused ion beam in Example 1 is shown.

[0081] Gold was selected as the material for preparing TEM samples, and TEM samples with a thickness of about 50 nm were prepared.

[0082] First, the bulk sample is placed in the focused ion beam system, and the copper mesh used to transfer the sample is placed. Adjust the sample stage so that the upper surface of the bulk sample is perpendicular to the direction of the ion beam. like Figure 6a to Figure 6d As shown, a Pt protective layer is dep...

Embodiment 2

[0090] Platinum was selected as the material for preparing TEM samples, and a TEM sample with a thickness of 80 nm was prepared.

[0091] First, the bulk sample is placed in the focused ion beam system, and the copper mesh used to transfer the sample is placed. Adjust the sample stage so that the upper surface of the bulk sample is perpendicular to the direction of the ion beam. A Pt protective layer was deposited on the preparation area of the bulk sample by the focused ion beam assisted deposition method with a high voltage of 30kV and a beam current of 1.5nA. The Pt protective layer had a length of 16 μm, a width of 1.5 μm, and a thickness of 4 μm.

[0092] First use the focused ion beam of high voltage 30kV, beam current 9nA and Regular Cross-section method to dig holes around the sample preparation area, and then use the high voltage 30kV, beam current 2.5nA focused ion beam and Cleaning Cross-section method to carry out the sample preparation area The surrounding pits...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com