Carrier, preparation method thereof, Fischer-Tropsch synthesis catalyst, and Fischer-Tropsch synthesis method

A Fischer-Tropsch synthesis and catalyst technology, used in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of high stability and low, achieve excellent performance, Process simplification and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] According to a first aspect of the present invention, a method for preparing a carrier is provided, the method comprising:

[0019] The carrier precursor is subjected to water vapor treatment in an atmosphere containing water vapor to obtain a carrier, the atmosphere containing water vapor contains water vapor and air, and the content of water vapor is 50-90% by volume;

[0020] The conditions of water vapor treatment include: the temperature is 400-700°C, the time is 1-10h, and the volumetric space velocity of air is 200-3000h -1 .

[0021] In the prior art, the carrier precursor is often extruded to obtain a carrier that meets the requirements of use. In the preparation method provided by the present invention, the carrier precursor is directly subjected to the water vapor treatment in an atmosphere containing water vapor without extrusion molding. The average pore diameter of the prepared support can also be increased by steam treatment under specific conditions. ...

Embodiment approach

[0024] According to a preferred embodiment of the present invention, in the atmosphere containing water vapor, the content of water vapor is 60-80% by volume. In the course of research, the present invention finds that the water vapor treatment of the molded article is more conducive to the increase of the average pore diameter of the carrier through the atmosphere containing water vapor and air with the preferred water vapor content of the present invention.

[0025] According to the present invention, preferably, the type of the carrier precursor and the conditions of the water vapor treatment make the average pore diameter of the prepared carrier larger than that of the carrier precursor, which is characterized by BET low-temperature nitrogen adsorption. n is at least Δn=n2-n1, n1 is the average pore diameter of the carrier precursor, and n2 is the average pore diameter of the prepared carrier.

[0026] According to a preferred embodiment of the present invention, the amo...

preparation example 1

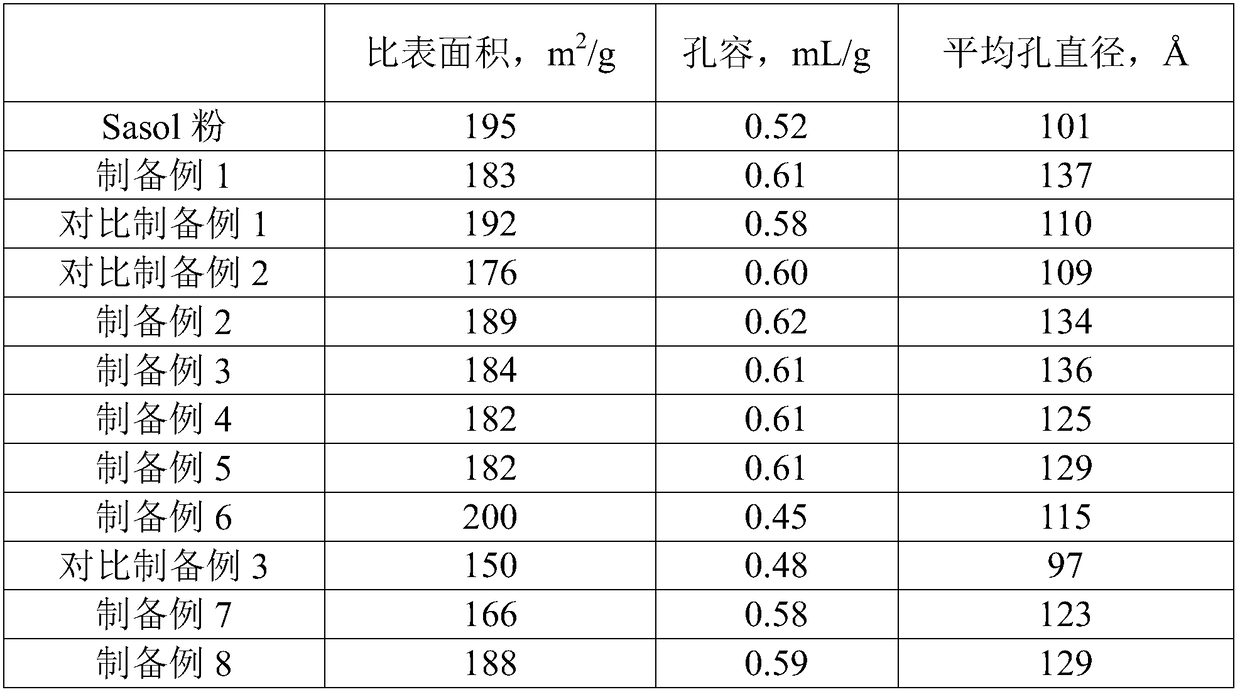

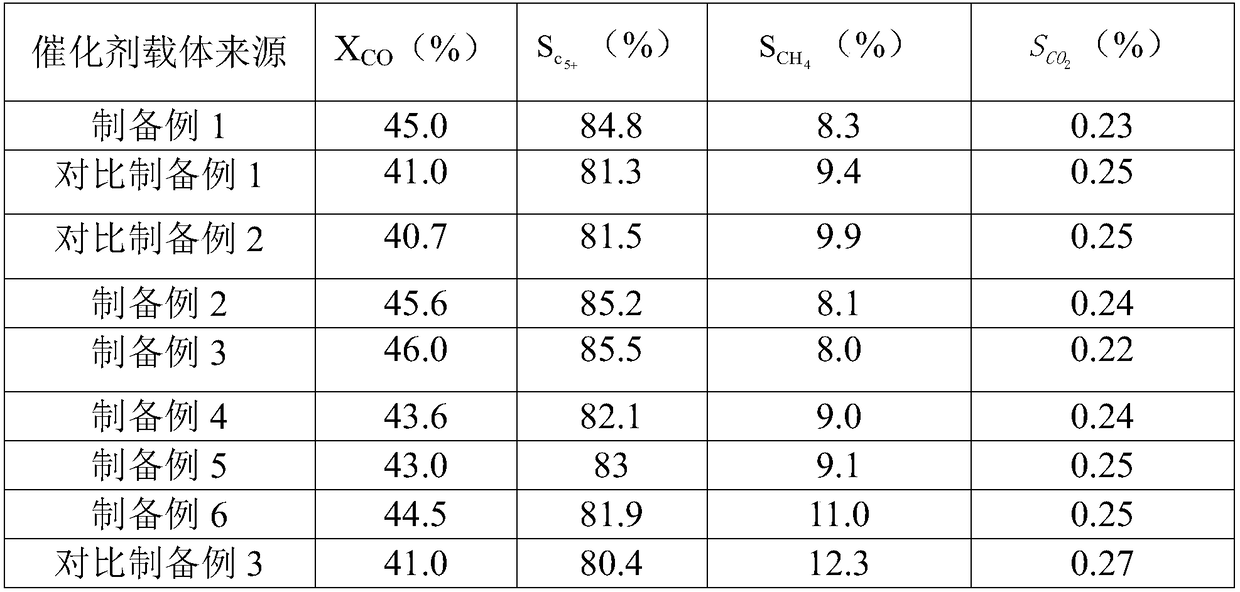

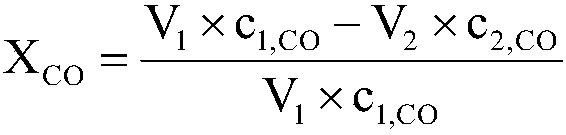

[0060] Get particle diameter and be 200 grams of pseudo-boehmite powder (purchased from Sasol company, hereinafter referred to as Sasol powder, the amount of sulfur-containing compound of this powder is less than 1000 μ g / g, pore volume, mean pore diameter and specific surface area are listed as 10-120 μ m In Table 1, the same below), after dissolving 2 grams of PEG400 and 4 grams of PVP in 200mL water, they were added to the above-mentioned pseudo-boehmite powder and mixed to obtain a mixed material, and an atmosphere containing water vapor was passed into the mixed material for water Steam treatment, the conditions of the steam treatment include: in an atmosphere with a water vapor to air volume ratio of 70:30, the volumetric space velocity of the air is 300h -1 , treated at a temperature of 550° C. for 4 h to obtain carrier A1. The pore volume, average pore diameter and specific surface area of the carrier are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com