Fresh-keeping packaging bag, and preparation method thereof and application thereof

A technology of packaging bags and fresh-keeping film, which is applied in the field of fresh-keeping packaging bags, can solve problems such as high energy consumption and complicated fresh-keeping process, and achieve the effects of improving quality, reducing bacterial growth, and extending shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

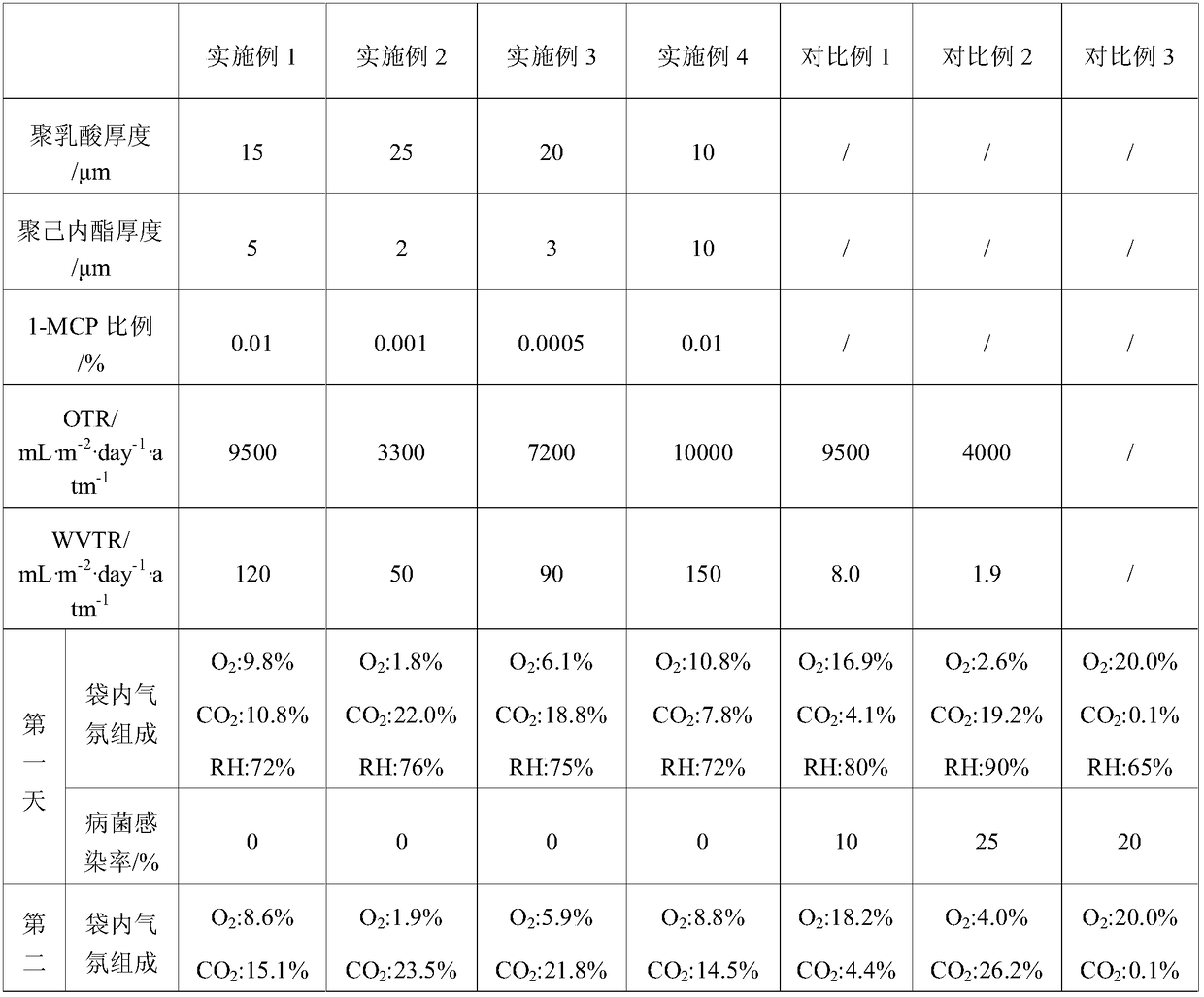

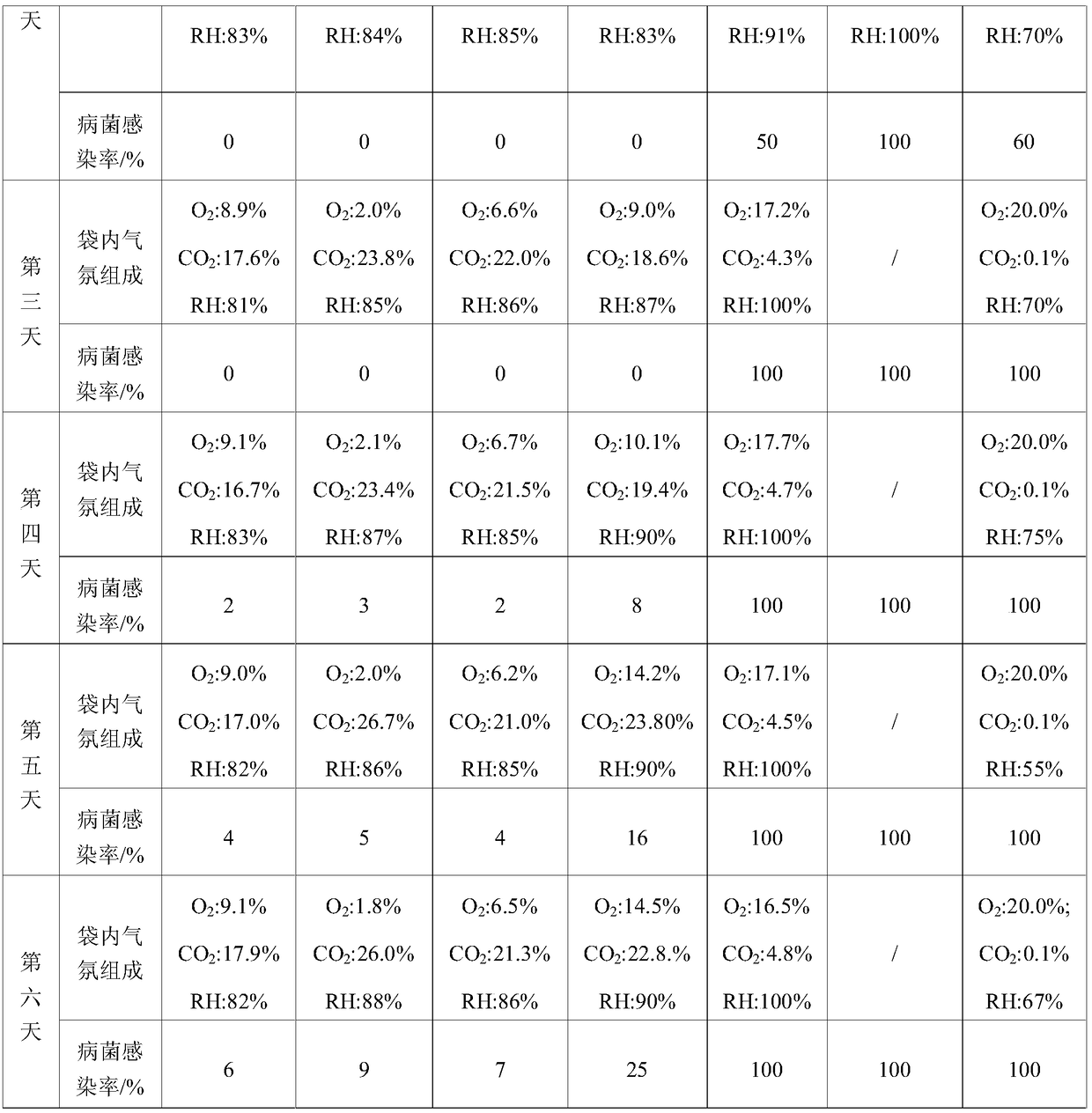

Examples

preparation example Construction

[0025] In a typical embodiment, the present application also provides a method for preparing a fresh-keeping packaging bag, which includes the following steps: S1, first prepare a polylactic acid film; S2, arrange poly(caprolactone) on the prepared polylactic acid film An ester film, wherein the polycaprolactone film includes a polycaprolactone base film and a 1-MCP release agent dispersed in the polycaprolactone base film; and then forms any one of the above fresh-keeping packaging bags.

[0026] The preparation method of the fresh-keeping packaging bag provided in the present application has a simple process flow, and the fresh-keeping of fruits and vegetables at room temperature can be realized only by using the fresh-keeping packaging bag. It avoids a series of cumbersome fresh-keeping processes such as low-temperature refrigeration, controlled-atmosphere preservation and dipping treatment for fruits and vegetables in conventional fresh-keeping technologies.

[0027] In a ...

Embodiment 1

[0038] Set the temperature of the extrusion section on the casting equipment to 170°C, the die temperature to 230°C, and the cooling roll temperature to 25°C to prepare a polylactic acid film with a thickness of 15 μm and a width of 50 cm; then set the extrusion coating The temperature of the screw extrusion section of the equipment is 70°C, the die opening temperature is 90°C, and the cooling roll temperature is 20°C, and a layer of polycaprolactone film with a thickness of 5 μm is extruded on the polylactic acid film. Then on the dry composite production line, the polycaprolactone / polylactic acid film produced above is installed on the first unwinding position, and the polycaprolactone film side of the composite film is kept facing up, and the temperature of the setting pressure roller is 70°C, set the unwinding line speed to 50 m / min, spray commercially available 1-MCP / cyclodextrin powder on the film before the film passes through the pressing roller, the spraying rate is 1....

Embodiment 2

[0040] The difference from Example 1 is that the temperature of the extrusion section of the casting equipment is 230° C., the temperature of the cooling roll is 35° C., and the thickness of the prepared polylactic acid film is 25 μm. The temperature of the extrusion section of the extrusion coating equipment was 90° C., the temperature of the cooling roll was 25° C., and the thickness of the prepared polycaprolactone film was 2 μm. The unwinding line speed was 70 m / min, and the spray rate of 1-MCP / cyclodextrin powder was 0.035 g / min (1-MCP accounted for 0.001% of the polycaprolactone film).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com