Absorbable suture and preparation method thereof

A technique of suture and silk thread, which is applied in the field of biomaterial preparation to achieve the effect of maintaining mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the above-mentioned absorbable suture, comprising,

[0041] Weaving step: interweave and weave multiple strands of silk threads to obtain the suture body;

[0042] Desericin removal step: After heating the degumming agent solution, soak the suture main body in the degumming agent, maintain the water temperature, then take out the suture main body, wash the suture main body with water for 1-10 times, repeat degumming agent soaking and washing step 2 -After 6 times, dry to get absorbable uncoated suture;

[0043] Coating step: Soak the absorbable uncoated suture in the silk fibroin solution, take it out and dry it, repeat 1-5 times to get the coated suture;

[0044] Forming step: the coated suture is cross-linked to obtain absorbable suture.

[0045] As a further embodiment, in the desericin step, the degumming agent is 0.01-0.03 mol / L sodium carbonate, 0.04-0.08 mol / L sodium bicarbonate or 3-5 mol / L calcium chloride.

[0046] As a further emb...

Embodiment 1

[0053] An absorbable suture prepared as follows:

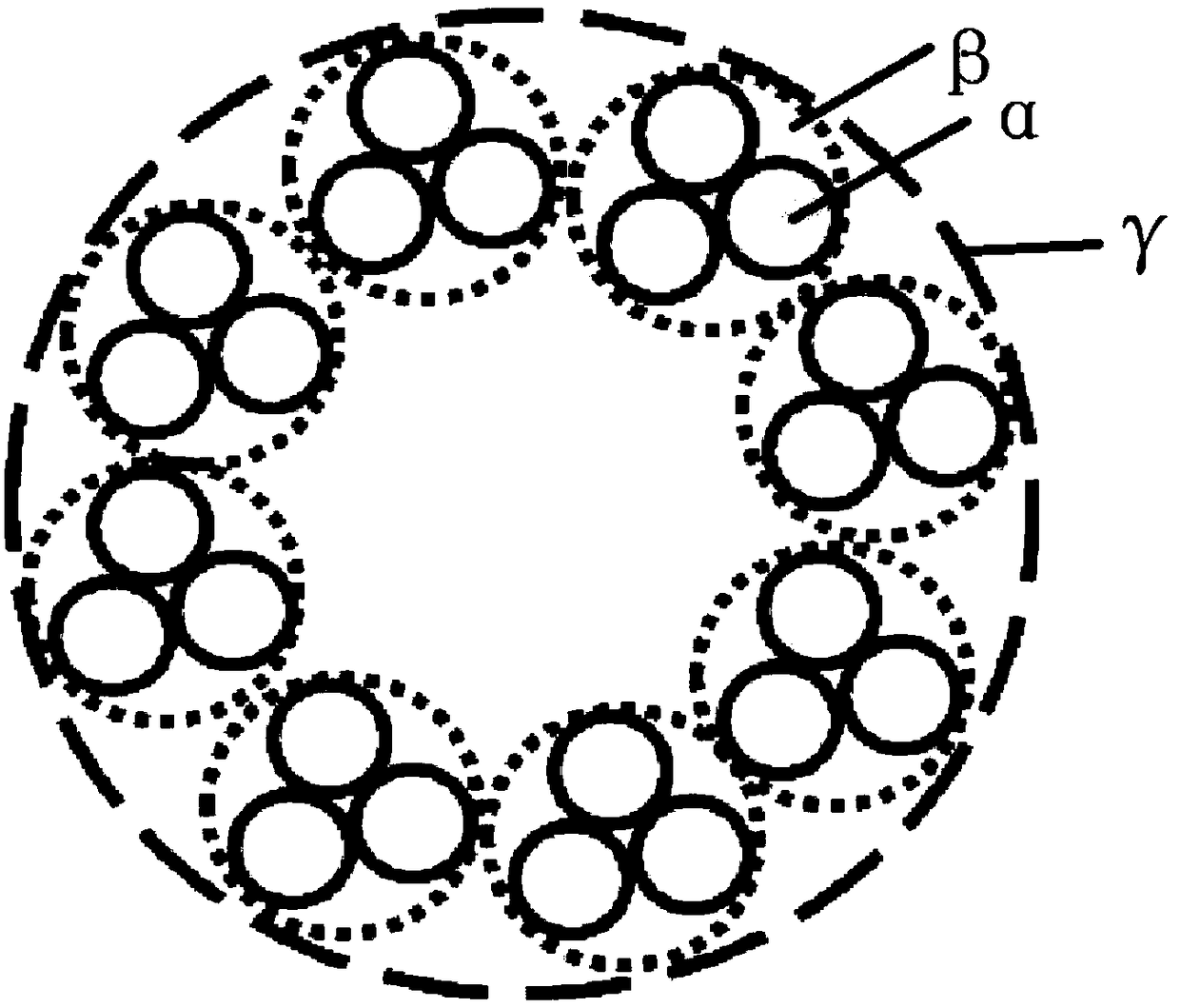

[0054] Weaving step: interweave 140 mulberry silk threads and weave them in a core-wrapping manner. The inner core is 12 silk threads to obtain the suture body;

[0055]Desericin removal step: heat the degumming agent solution to 100°C, soak the suture main body in the degumming agent, the mass volume ratio of the suture main body and the degumming agent is 1g: 200mL, maintain the water temperature for 30 minutes, and the degumming agent is 0.03mol / L sodium carbonate solution, then take out the suture main body, and then wash the suture main body once with water, the mass volume ratio of the suture main body and water is 1g:100mL, repeat the degumming agent soaking and water washing steps for 3 times, dry, dry The temperature is 80°C, and the drying time is 6 hours to obtain absorbable uncoated sutures;

[0056] Coating step: Soak the absorbable uncoated suture in the silk fibroin solution, the concentration of the silk fibr...

Embodiment 2

[0059] An absorbable suture prepared as follows:

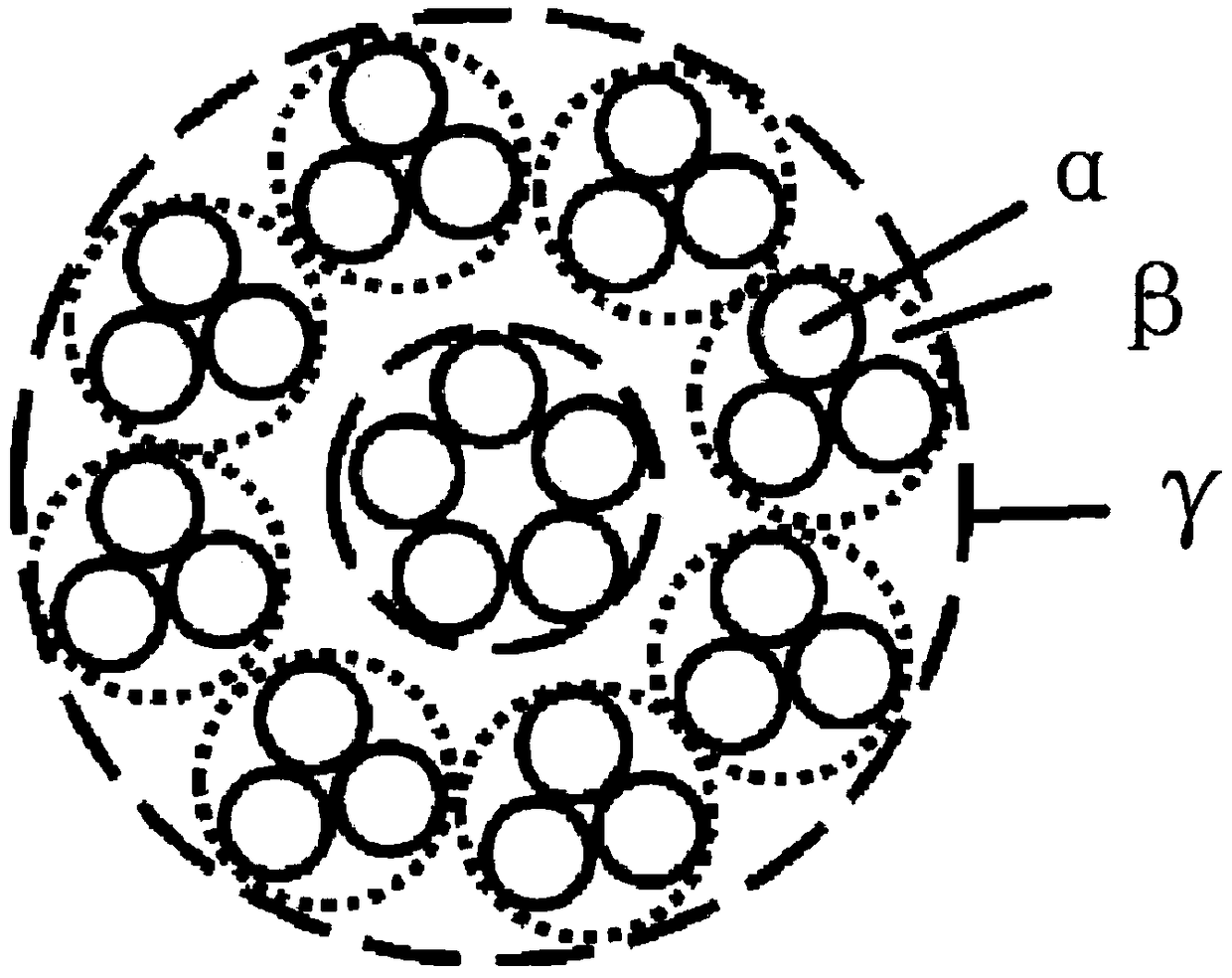

[0060] Weaving step: interweaving and weaving 80 strands of silk threads, each strand containing 5 mulberry silks, to obtain the main body of the suture;

[0061] Desericin removal step: heat the degumming agent solution to 90°C, soak the suture body in the degumming agent, the mass volume ratio of the suture main body and the degumming agent is 1g: 100mL, maintain the water temperature for 60 minutes, and the degumming agent is 0.08mol / L of sodium bicarbonate solution, then take out the suture main body, and then wash the suture main body with water for 3 times, the mass volume ratio of the suture main body and water is 1g:100mL, repeat the degumming agent soaking and water washing steps for 3 times, dry, The drying temperature is 60°C and the drying time is 12 hours to obtain absorbable uncoated sutures;

[0062] Coating step: Soak the absorbable uncoated suture in the silk fibroin solution, the concentration of the silk f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com