Conductive elastomer roller, and manufacturing method and application thereof

A manufacturing method and elastomer technology, which are applied in the direction of electric recording process applying charge pattern, equipment and circuit applying electric recording process of charge pattern, etc., can solve the problems of high price, disadvantage and lower product cost of liquid silicone rubber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] 1. Elastomer composition

[0109] The elastomer composition of the present embodiment is made up of the following components by weight:

[0110] 100 parts of basic materials, 0.8 parts of lithium perchlorate (ion conductive agent), 6.5 parts of zinc oxide (activator), 1 part of stearic acid (activator), 25 parts of activated calcium carbonate (filler), sulfur (vulcanizing agent) 1.5 parts, 1.0 parts of dibenzothiazole disulfide (vulcanization accelerator) and 1.0 parts of tetramethylthiuram disulfide (vulcanization accelerator).

[0111] Among them, the base material consists of 50 parts by weight of chloroether rubber (the second main material, trade name: Hydrin T3106) with a Mooney viscosity (ML1+4, 100°C) of about 60 and 50 parts by weight of a Mooney viscosity (ML1+ 4, 100°C) is about 33, and the mass content of acrylonitrile is about 34% of nitrile rubber (the first main material, trade name: NBR6230).

[0112] After preparing the materials according to the abov...

Embodiment 2

[0126] The elastomer composition of the present embodiment is made up of the following components by weight:

[0127] 100 parts of basic materials, 1.0 parts of ST-90 antistatic agent (ion conductive agent), 6.5 parts of zinc oxide, 1 part of stearic acid, 25 parts of activated calcium carbonate, 1.5 parts of sulfur, 1.0 parts of dibenzothiazole disulfide and two 1.0 parts of vulcanized tetramethylthiuram; wherein, the base material is about 60 epichlorohydrin rubbers (the second main body material, trade name: Hydrin T3106) and 30 parts by weight of mixed nitrile rubber (the first main material, trade name: Nipol DN223) with a Mooney viscosity (ML1+4, 100° C.) of about 35.

[0128] After preparing materials according to the above weight parts, firstly mix the epichlorohydrin rubber and mixed nitrile rubber in the mixer, and then add ST-90 antistatic agent, zinc oxide, stearic acid, and active calcium carbonate in the internal mixer Mix evenly, then add sulfur, dibenzothiazol...

Embodiment 3

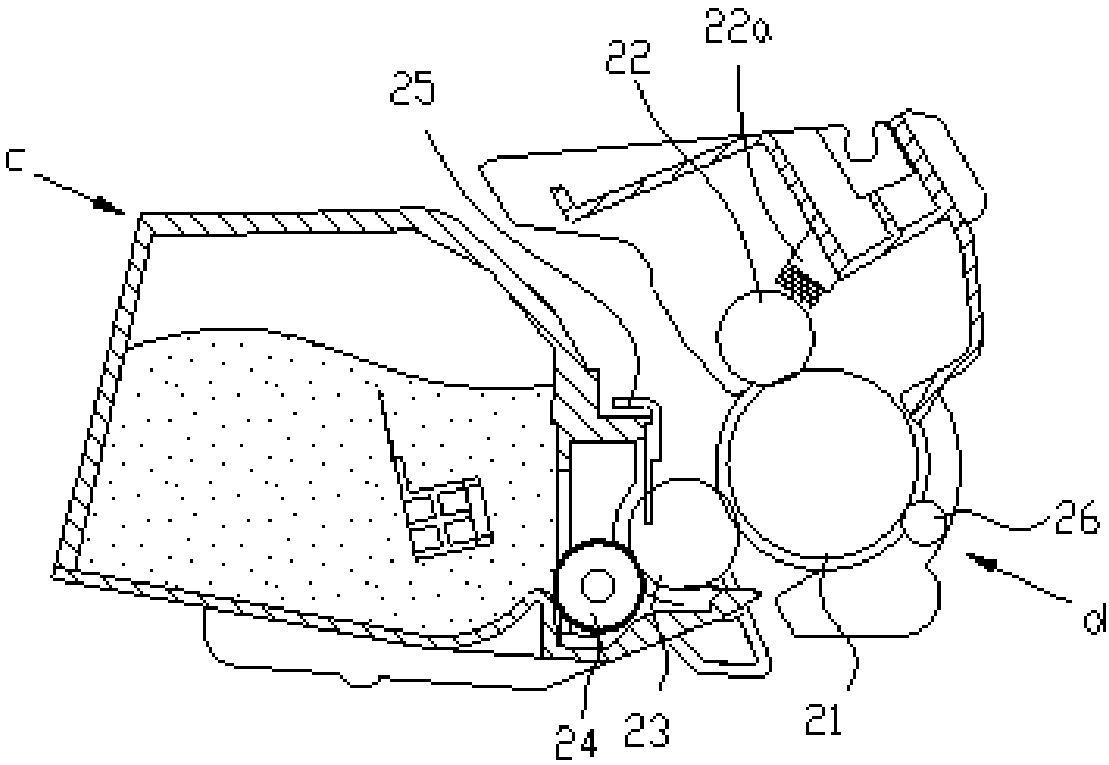

[0133] Except that the elastomer composition is composed of the following components by weight, the rest is the same as in Example 1 to prepare a conductive elastomer roller 23 .

[0134] Elastomer composition is made up of following components by weight:

[0135] 100 parts of basic materials, 1.6 parts of KJ-100 antistatic agent (ion conductive agent), 6.5 parts of zinc oxide, 1 part of stearic acid, 25 parts of activated calcium carbonate, 1.5 parts of sulfur, 1.0 parts of dibenzothiazole disulfide and two 1.0 parts of vulcanized tetramethylthiuram; wherein, the base material is about 60 epichlorohydrin rubbers (the second main body material, trade name: Hydrin T3106) and Composed of 30 parts by weight of epichlorohydrin rubber (the first main material, trade name: Hydrin T3106XL) with a Mooney viscosity (ML1+4, 100° C.) of about 30.

[0136] The minimum torque value M of the above-mentioned elastomer composition after mixing before vulcanization L is 0.70dN·m. In additio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com