Diatomite sintered plate and preparation process thereof

A preparation process, diatomite technology, applied in clay products, other household utensils, applications, etc., can solve the problems that the production process has not been effectively solved, and the product size cannot be developed to a large size, so as to achieve light weight and high strength , strong decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

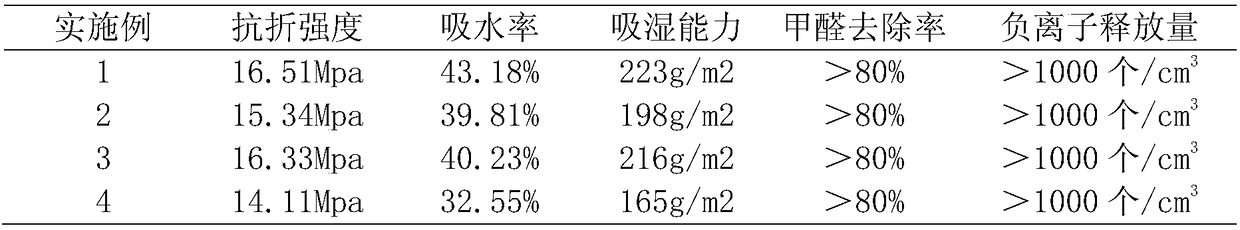

Examples

Embodiment 1

[0030] In this embodiment, a diatomite sintered board is prepared, including a blank and a glaze. In terms of mass percentage, the raw materials and the ratio of the blank are: 67% diatomite ore, 20% Jilin soil, and 0.5% sodium carbonate. , Wollastonite 3%, talc 4%, waste porcelain particles 5%, basalt fiber 0.5%; the raw materials and proportions of the glaze are: diatomite filter aid 55%, washed kaolin 5%, frit 30%, sodium carbonate 2%, calcium carbonate 3%, talc 4%, tourmaline 1%.

[0031] The process for preparing diatomite sintered board using the above-mentioned raw materials includes the following steps:

[0032] (1) Blank mixing: Weigh the raw materials of each component. The particle size of the raw materials should be between 60 and 150 meshes through a standard sieve. The raw materials are evenly mixed before use;

[0033] (2) Blank granulation: send the mixed raw materials into the mixing granulator, and at the same time add an appropriate amount of water to the raw mate...

Embodiment 2

[0042] In this embodiment, a diatomite sintered plate is prepared, including a blank and a glaze. In terms of mass percentage, the raw materials and the ratio of the blank are: 57% diatomite ore, 20% Jilin soil, and 1.5% sodium carbonate. , Wollastonite 5%, talc 6%, waste porcelain particles 10%, basalt fiber 0.5%; the raw materials and proportions of the glaze are: diatomite filter aid 56%, washed kaolin 10%, frit 20%, sodium carbonate 1%, calcium carbonate 5%, talc 6%, tourmaline 2%.

[0043] The process for preparing diatomite sintered board using the above-mentioned raw materials includes the following steps:

[0044] (1) Blank mixing: Weigh the raw materials of each component. The particle size of the raw materials should be between 60 and 150 meshes through a standard sieve. The raw materials are evenly mixed before use;

[0045] (2) Blank granulation: send the mixed raw materials into the mixing granulator, and at the same time add an appropriate amount of water to the raw ma...

Embodiment 3

[0054] In this embodiment, a diatomite sintered plate is prepared, including a blank and a glaze. The raw materials used and the ratio of the blank are calculated by mass percentage: the raw materials and the ratio are: 65% diatomite ore, Jilin soil 10%, sodium carbonate 1%, wollastonite 5%, talc 8%, waste porcelain particles 10%, basalt fiber 1%; the raw materials and ratio of the glaze are: diatomite filter aid 44%, Washed kaolin 15%, clinker 20%, sodium carbonate 3%, calcium carbonate 7%, talc 8%, tourmaline 3%.

[0055] The process for preparing diatomite sintered board using the above-mentioned raw materials includes the following steps:

[0056] (1) Blank mixing: Weigh the raw materials of each component. The particle size of the raw materials should be between 60 and 150 meshes through a standard sieve. The raw materials are evenly mixed before use;

[0057] (2) Blank granulation: send the mixed raw materials into the mixing granulator, and at the same time add an appropriate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com