High temperature resistant polymer gel for medium and low temperature gelation and preparation method and application thereof

A high-temperature-resistant polymer and gel-forming technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of poor high-temperature resistance and difficulty in gel-forming, achieve excellent gel-forming properties, and improve crude oil recovery. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The screening of embodiment 1 heat stabilizer

[0041] Prepare 5 mass percentages of 1% acrylamide-2-acrylamide-2-methylpropanesulfonic acid-vinylpyrrolidone terpolymer aqueous solution, the mass percentage of cross-linking agent chromium acetate is 0.15%, cross-linking aid Agent is mass percent 0.2% resorcinol and 0.4% urotropine, adding mass percent is respectively 0.02%, 0.05%, 0.10% heat stabilizer: 1) thiourea; 2) thiourea and cobalt chloride ( The mass ratio is 2:1). Place the cross-linking solution at 140°C to form a gel, and observe the temperature resistance effect after 5 days. The evaluation of thermal stability in this example is mainly by observing the dehydration condition (volume fraction) of the gel. The influence of different thermal stabilizers on the thermal stability of the gel is shown in Table 2.

[0042] Table 2 Dehydration rate of AM-AMPS-NVP terpolymer reacted with cross-linking agent for 5 days under different thermal stabilizers

[0043] ...

Embodiment 2

[0045]Example 2 Screening of the concentration of acrylamide-2-acrylamide-2-methylpropanesulfonic acid-vinylpyrrolidone terpolymer

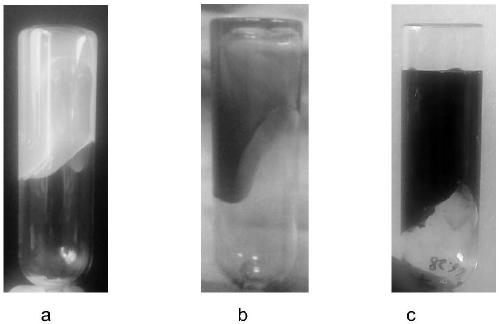

[0046] Prepare an aqueous solution of acrylamide-2-acrylamido-2-methylpropanesulfonic acid-vinylpyrrolidone terpolymer with a mass percentage of 0.2%-1.0%, and add 0.15% of a crosslinking agent chromium acetate, 0.2% methane Hydroquinone, 0.4% urotropine, 0.05% thiourea and cobalt chloride (mass ratio: 2:1) were placed at 50°C, 70°C, and 90°C to form gels respectively, and the state of gelation was observed. The temperature resistance performance was regularly inspected in a constant temperature oven at 140°C, and the observation results are shown in Table 3.

[0047] Table 3 The optimal experiment of AM-AMPS-NVP terpolymer concentration

[0048]

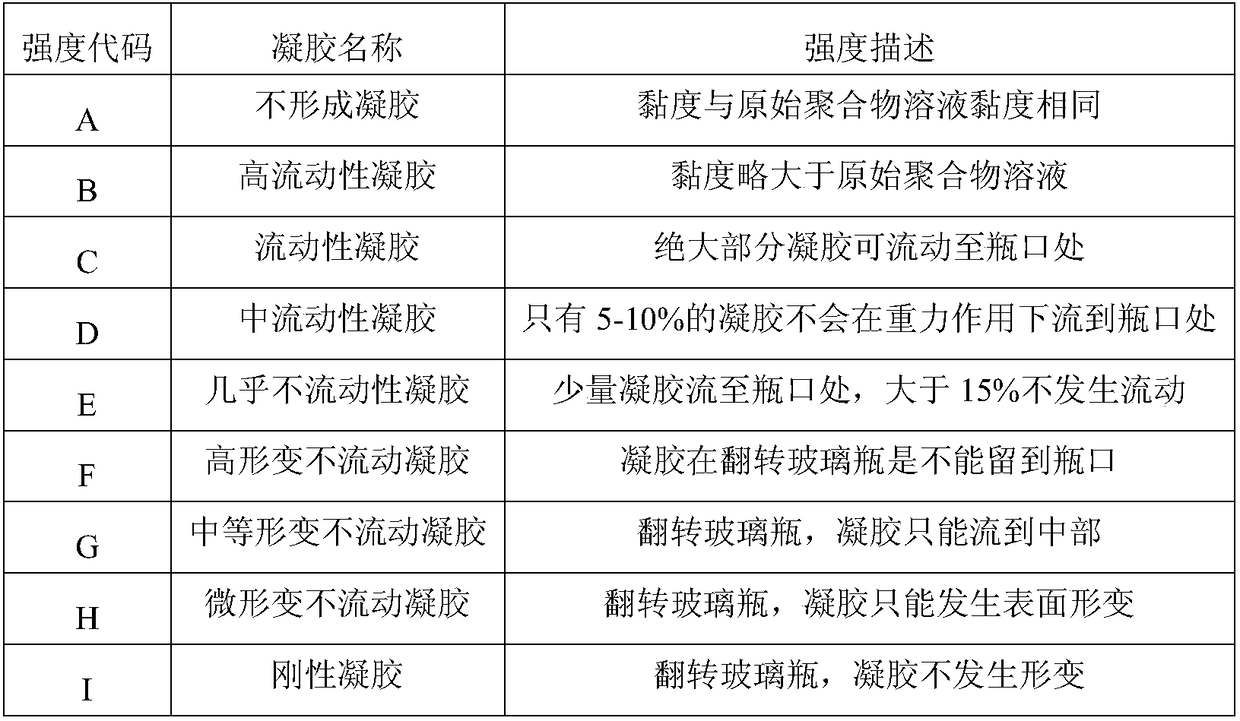

[0049] It can be known from Table 3 that the greater the mass percentage of the main agent acrylamide-2-acrylamide-2-methylpropanesulfonic acid-vinylpyrrolidone terpolymer, the greater the gel stre...

Embodiment 3

[0050] The screening of embodiment 3 crosslinking agent chromium acetate concentration

[0051] Prepare an aqueous solution of acrylamide-2-acrylamide-2-methylpropanesulfonic acid-vinylpyrrolidone terpolymer with a mass percentage of 0.8%, adding 0.2% resorcinol and 0.4% urotropine , 0.05% heat stabilizer (thiourea and cobalt chloride with a mass ratio of 2:1) and chromium acetate crosslinking agent with different mass percentages were placed at 50°C, 70°C, and 90°C to form gels respectively, and the formation was observed. The glue state, and placed in a constant temperature oven at 140 ℃ to regularly inspect its temperature resistance performance, the observation results are shown in Table 4.

[0052] Table 4 Optimum experiment of crosslinking agent chromium acetate concentration

[0053]

[0054]

[0055] As shown in Table 4, the concentration of the crosslinking agent has a great influence on the gel formation. The greater the concentration of chromium acetate, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com