Selenium-rich iron pot and manufacturing method thereof

An iron pot and selenium-enriched technology, which is applied in the selenium-enriched iron pot and its manufacturing field, can solve the problems of wasting selenium-containing raw materials and unsatisfactory selenium recovery rate, and achieve the effects of reducing waste, benefiting human health, and simple manufacturing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

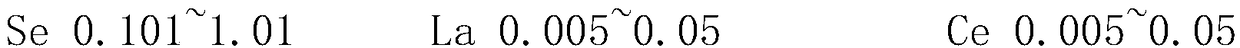

[0023] Weigh 9600g of pig iron, 200g of selenium-copper alloy and 200g of selenium-zinc alloy, put them in the cupola, preheat to 800°C, and then melt at 1200°C. The pot machine is die-cast into an iron pot. The iron pot is trimmed, polished inside and outside, and installed with ear handles, etc., to become an iron pot with beautiful appearance, economical and practical, and health care.

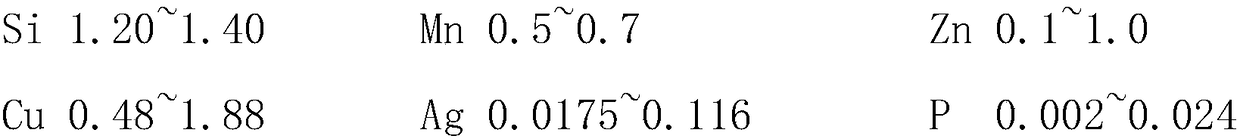

[0024] The obtained iron pan was analyzed for each component, and the obtained data are listed in Table 1. The analysis method is ICP-AES method, and the analysis instrument is HK-2000 plasma emission spectrometer.

[0025] Contents of each element in the iron pot in Table 1 Example 1

[0026]

[0027] Use the iron pot invented in this embodiment to boil 1000 milliliters of deionized water and concentrate it to 100 milliliters after 1 hour. After measurement, the water contains various trace elements, and the amount released is shown in Table 2. This data is analyzed and tested by Shan...

Embodiment 2

[0032] Weigh 9700g of pig iron, 150g of selenium-copper alloy, and 150g of selenium-zinc alloy, and place them in a cupola, preheat to 820°C, and then melt at 1210°C. The pot machine is die-cast into an iron pot. The iron pot is trimmed, polished inside and outside, and installed with ear handles, etc., to become an iron pot with beautiful appearance, economical and practical, and health care.

[0033] The obtained iron pan was analyzed for each component, and the obtained data are listed in Table 3. The analysis method is ICP-AES method, and the analysis instrument is HK-2000 plasma emission spectrometer.

[0034] Contents of each element in the iron pan in Table 3 Example 2

[0035]

[0036] Boil 1000 milliliters of deionized water with the iron pot invented in this embodiment, and concentrate it to 100 milliliters after 1 hour. After measurement, the water contains various trace elements, and the amount released is shown in Table 4. The data are analyzed and tested by ...

Embodiment 3

[0040] Weigh 9800g of pig iron, 100g of selenium-copper alloy and 100g of selenium-zinc alloy, put them in the cupola, preheat to 850°C, and then melt at 1230°C. The pot machine is die-cast into an iron pot. The iron pot is trimmed, polished inside and outside, and installed with ear handles, etc., to become an iron pot with beautiful appearance, economical and practical, and health care.

[0041] The obtained iron pan was analyzed for each component, and the obtained data are listed in Table 5. The analysis method is ICP-AES method, and the analysis instrument is HK-2000 plasma emission spectrometer.

[0042] Each element content of iron pan in table 5 embodiment 3

[0043]

[0044] Use the iron pot invented in this embodiment to boil 1000 milliliters of deionized water and concentrate it to 100 milliliters after 1 hour. After measurement, the water contains various trace elements, and the amount released is shown in Table 6. This data is analyzed and tested by Shanghai ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com