Preparation method of flame-retardant Lyocell fiber

A fiber and concentration technology, applied in the manufacture of fire-resistant and flame-retardant filaments, fiber chemical characteristics, single-component cellulose artificial filaments, etc., can solve the difficulty in combining organic phosphorus flame retardants with cellulose fibers and the flame-retardant effect of fabrics Weakening, organophosphorus flame retardant falling off and other problems, to achieve the effect of strong binding force, low price, and little environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

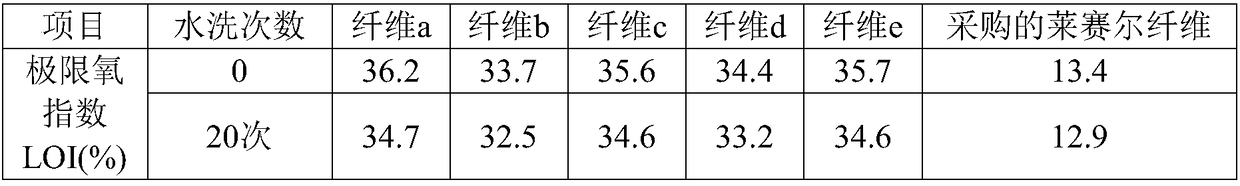

Examples

Embodiment 1

[0021] A kind of preparation method of flame-retardant lyocell fiber of the present embodiment, described preparation method comprises the following steps:

[0022] (1) Preparation of spinning solution: the aqueous solution of NMMO with a mass fraction of 50.4% is distilled under reduced pressure to an aqueous solution of NMMO of 86.7%, tris (2,3-dibromopropyl) phosphate and cotton pulp (Shandong Yinying Chemical Fiber Co., Ltd.) dissolved in NMMO aqueous solution, wherein the mass ratio of tris(2,3-dibromopropyl) phosphate to cotton pulp is 1:25, the mass (g) of cotton pulp and the volume of NMMO aqueous solution ( mL) with a bath ratio of 1:15, stirred and dissolved under vacuum at 105°C for 3.5 hours in a reactor to obtain a uniform spinning solution with a mass fraction of 15.8%;

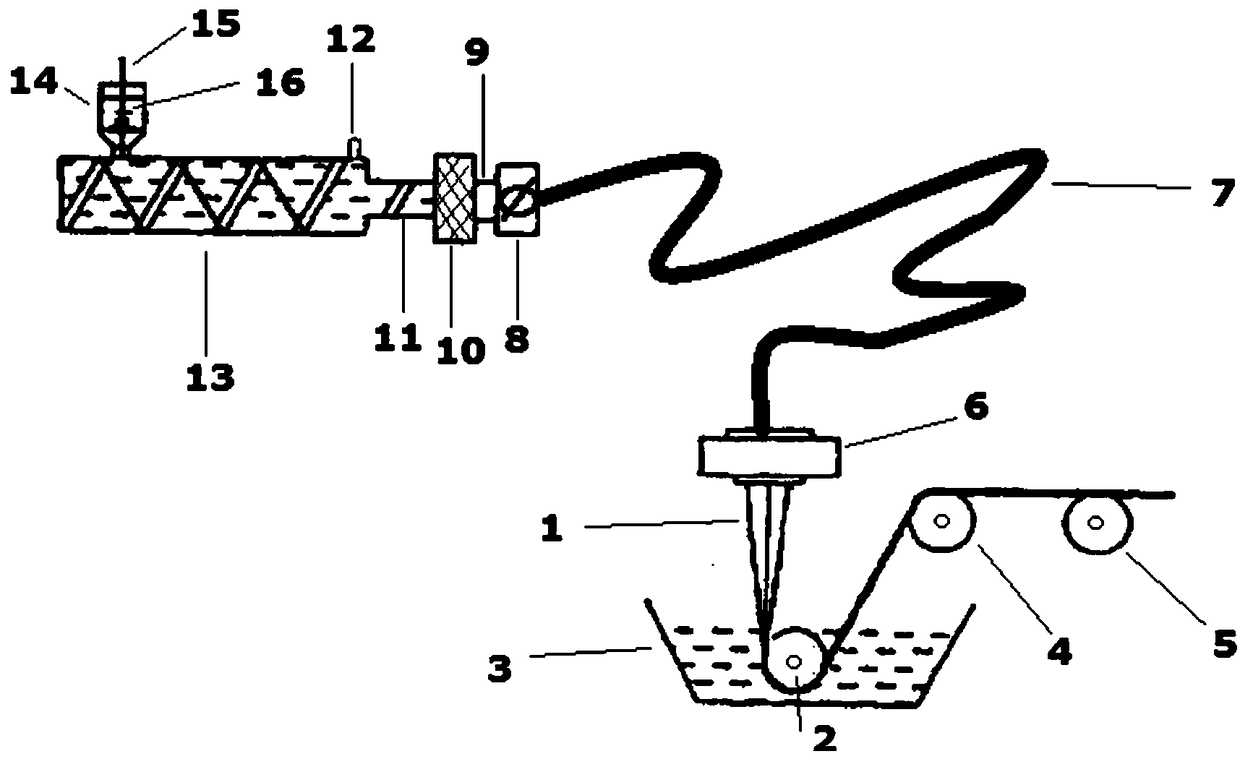

[0023] (2) Spinning of lyocell fibers: Add the spinning solution treated in step (1) into a screw extruder, further dissolve at 90°C, then filter, and enter the spinning system, wherein the air ...

Embodiment 2

[0030] A kind of preparation method of flame-retardant lyocell fiber of the present embodiment, described preparation method comprises the following steps:

[0031] (1) Preparation of spinning solution: the aqueous solution of NMMO with a mass fraction of 52.6% is distilled under reduced pressure to an aqueous solution of NMMO of 88.7%, tris (2,3-dibromopropyl) phosphate and cotton pulp (Shandong Yinying Chemical Fiber Co., Ltd.) dissolved in NMMO aqueous solution, wherein the mass ratio of tris(2,3-dibromopropyl) phosphate to cotton pulp is 1:30, the mass (g) of cotton pulp and the volume of NMMO aqueous solution ( mL) with a bath ratio of 1:20, stirred and dissolved under vacuum at 125°C for 4 hours in a reactor to obtain a uniform spinning solution with a mass fraction of 17.6%;

[0032] (2) Spinning of lyocell fiber: Add the spinning solution treated in step (1) into a screw extruder, further dissolve it at 100°C, then filter and enter the spinning system, wherein the air ...

Embodiment 3

[0039] A kind of preparation method of flame-retardant lyocell fiber of the present embodiment, described preparation method comprises the following steps:

[0040] (1) Preparation of spinning solution: the aqueous solution of NMMO with a mass fraction of 54.9% is distilled under reduced pressure to an aqueous solution of NMMO of 87.6%, tris (2,3-dibromopropyl) phosphate and cotton pulp (Shandong Yinying Chemical Fiber Co., Ltd.) dissolved in NMMO aqueous solution, wherein the mass ratio of tris(2,3-dibromopropyl) phosphate to cotton pulp is 1:26, the mass (g) of cotton pulp and the volume of NMMO aqueous solution ( mL) with a bath ratio of 1:20, stirred and dissolved under vacuum at 105°C for 3 hours in a reactor to obtain a uniform spinning solution with a mass fraction of 16.6%;

[0041] (2) Spinning of lyocell fibers: Add the spinning solution treated in step (1) into a screw extruder, further dissolve at 100°C, then filter, and enter the spinning system, wherein the air g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Dry breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com