A kind of method that takes bamboo as raw material to prepare lyocell fiber

A bamboo fiber and fiber technology, which is applied in the field of preparing lyocell fiber, can solve the problems of high cost, poor quality, immature development of bamboo lyocell fiber, etc., and achieve the goals of less environmental pollution, short growth cycle, and increased economic value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

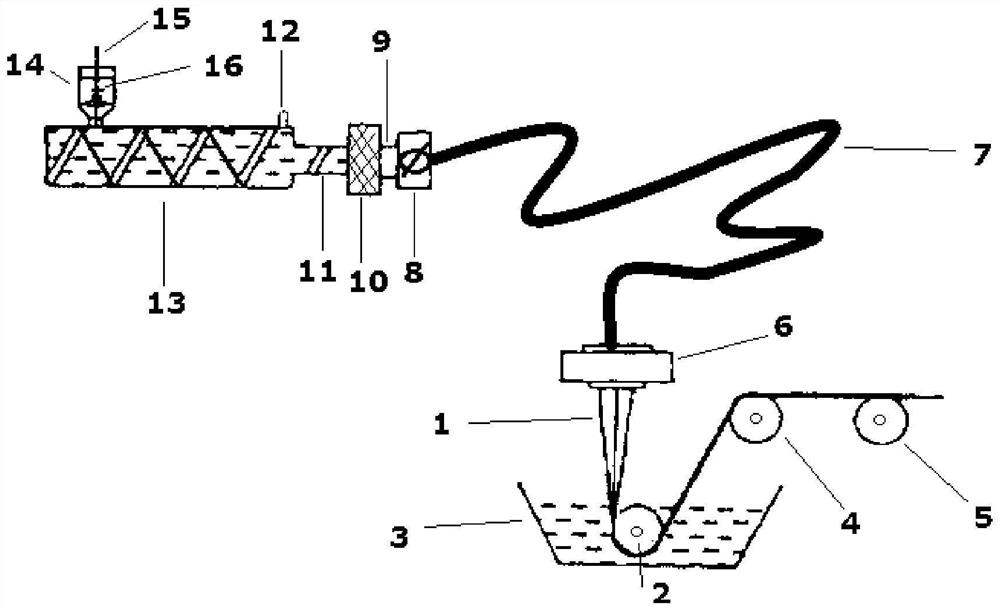

Method used

Image

Examples

Embodiment 1

[0026] (1) Cleaning: take 2000 grams of raw bamboo, saw the raw bamboo, and saw it into irregular small pieces of raw bamboo. The length is 1-2 cm. The small piece of raw bamboo after sawing is cleaned with warm water, and a cleaning agent (water-based cleaning agent, produced by Shenzhen Yuanan Technology Co., Ltd.) is added. The amount of cleaning agent accounts for 0.01% of the small piece of raw bamboo, and the quality of the small piece of raw bamboo (g ) to the volume of the cleaning agent aqueous solution (mL) is 1:100, and rinse with tap water repeatedly after cleaning.

[0027] (2) Degumming of bamboo raw fibers: put the bamboo raw fibers treated in step (1) into pectinase with a mass concentration of 3 g / L, the treatment temperature is 50° C., and the enzyme action time is 48 hours.

[0028] (3) Removal of lignin: immerse the bamboo fiber treated in step (2) into 2g / L sodium hypochlorite solution, set the solution temperature to 40°C, the immersion time to be 2 hour...

Embodiment 2

[0038](1) Cleaning: Take 2000 grams of raw bamboo, saw the raw bamboo, and saw it into irregular small pieces of raw bamboo. The length is 4-5 cm. The small piece of raw bamboo after sawing is cleaned with warm water, and a cleaning agent (water-based cleaning agent, produced by Shenzhen Yuan'an Technology Co., Ltd.) is added. The amount of cleaning agent accounts for 0.05% of the small piece of raw bamboo, and the quality of the small piece of raw bamboo (g ) to the volume of the cleaning agent aqueous solution (mL) is 1:150, and rinse with tap water repeatedly after cleaning.

[0039] (2) Degumming of bamboo fiber: put the bamboo fiber treated in step (1) into pectinase with a mass concentration of 4 g / L, the treatment temperature is 60° C., and the enzyme action time is 48 hours.

[0040] (3) Removal of lignin: immerse the bamboo fiber treated in step (2) into 3g / L sodium hypochlorite solution, set the solution temperature to 45°C, the immersion time to be 2.5 hours, and t...

Embodiment 3

[0050] (1) Cleaning: take 2000 grams of raw bamboo, saw the raw bamboo, and saw it into irregular small pieces of raw bamboo. The length is 3-4 cm. The small piece of raw bamboo after sawing is cleaned with warm water, and a cleaning agent (water-based cleaning agent, produced by Shenzhen Yuanan Technology Co., Ltd.) is added. The amount of cleaning agent accounts for 0.06% of the small piece of raw bamboo, and the quality of the small piece of raw bamboo (g ) to the volume of the cleaning agent aqueous solution (mL) is 1:140, and rinse with tap water repeatedly after cleaning.

[0051] (2) Degumming of bamboo fiber: put the bamboo fiber treated in step (1) into pectinase with a mass concentration of 4 g / L, the treatment temperature is 55° C., and the enzyme action time is 40 hours.

[0052] (3) Removal of lignin: immerse the bamboo fiber treated in step (2) into 2.5g / L sodium hypochlorite solution, set the solution temperature to 45°C, the immersion time to be 2.5 hours, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com