Method for preparing antibacterial polyurethane fiber

A polyurethane fiber and polyurethane technology, applied in the field of polyurethane fiber, can solve problems such as weakening the antibacterial effect, and achieve the effects of less environmental pollution, easy availability of raw materials, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of preparation method of antibacterial polyurethane fiber of the present embodiment, described preparation method comprises the following steps:

[0019] (1) Preparation of spinning solution: Weigh 300 grams of polyurethane purchased from Tianhai Plastic Industry Co., Ltd., Hejian City, Hebei, and dissolve dimethyl diallyl ammonium chloride and polyurethane in dimethylformamide solvent at the same time , wherein the mass ratio of dimethyl diallyl ammonium chloride to polyurethane is 1:20, and it is configured as a solution with a mass concentration of 20%. Stir constantly during the dissolving process, and the dissolving time is 30 minutes, until the obtained solution is a stable liquid.

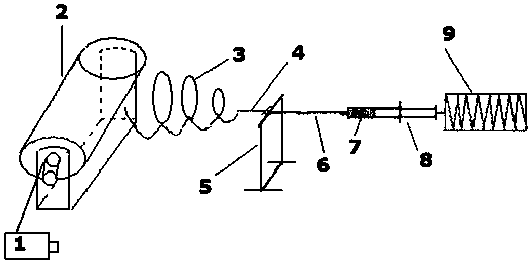

[0020] (2) Spinning of polyurethane fiber: the spinning solution prepared in step (1) is electrospun on an electrospinning machine, and the schematic diagram of the electrospinning machine device is as follows: figure 1 As shown, the spinning conditions are: voltage 6KV, jet s...

Embodiment 2

[0025] A kind of preparation method of antibacterial polyurethane fiber of the present embodiment, described preparation method comprises the following steps:

[0026] (1) Preparation of spinning solution: Weigh 300 grams of polyurethane purchased from Tianhai Plastic Industry Co., Ltd., Hejian City, Hebei, and dissolve dimethyl diallyl ammonium chloride and polyurethane in dimethylformamide solvent at the same time , wherein the mass ratio of dimethyl diallyl ammonium chloride to polyurethane is 1:24, and it is configured as a solution with a mass concentration of 30%. Stir continuously during the dissolving process, and the dissolving time is 40 min, until the prepared solution is a stable liquid.

[0027] (2) Spinning of polyurethane fiber: the spinning solution prepared in step (1) is electrospun on an electrospinning machine, and the schematic diagram of the electrospinning machine device is as follows: figure 1 As shown, the spinning conditions are: voltage 8KV, jet spe...

Embodiment 3

[0032] A kind of preparation method of antibacterial polyurethane fiber of the present embodiment, described preparation method comprises the following steps:

[0033] (1) Preparation of spinning solution: Weigh 300 grams of polyurethane purchased from Tianhai Plastic Industry Co., Ltd., Hejian City, Hebei, and dissolve dimethyl diallyl ammonium chloride and polyurethane in dimethylformamide solvent at the same time , wherein the mass ratio of dimethyl diallyl ammonium chloride to polyurethane is 1:25, and it is configured as a solution with a mass concentration of 40%. Stir continuously during the dissolving process, and the dissolving time is 60 min, until the obtained solution is a stable liquid.

[0034] (2) Spinning of polyurethane fiber: the spinning solution prepared in step (1) is electrospun on an electrospinning machine, and the schematic diagram of the electrospinning machine device is as follows: figure 1 As shown, the spinning conditions are: voltage 16KV, jet sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com