A kind of preparation method of superhydrophobic polylactic acid fiber

A polylactic acid fiber, super-hydrophobic technology, applied in fiber processing, fiber chemical characteristics, rayon manufacturing and other directions, can solve the problems of isocyanates that are not environmentally friendly, complex finishing processes, and large environmental pollution, and achieve low environmental pollution and low prices. , the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

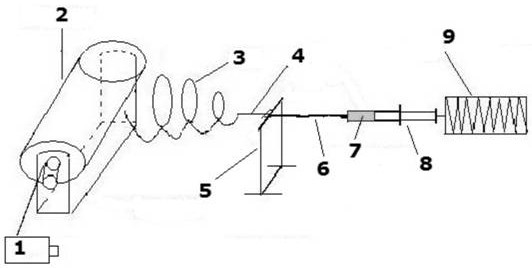

Method used

Image

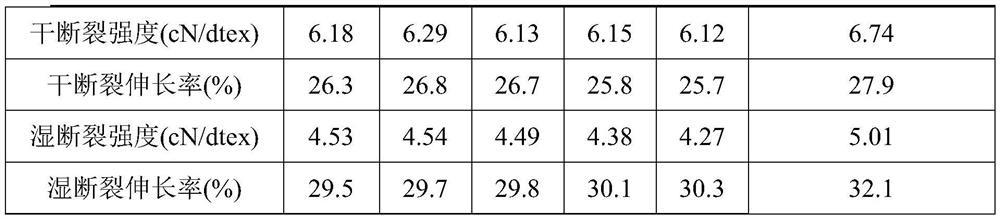

Examples

Embodiment 1

[0019] (1) Preparation of octacosanol: Weigh 300 grams of rice bran wax (produced by Haining Debang Chemical Co., Ltd.) and immerse in 2g / L sodium hydroxide aqueous solution, the quality of rice bran wax (g) and the volume of sodium hydroxide aqueous solution (mL) The bath ratio is 1:20, and the reaction is continuously stirred at 95°C for 10 hours. After the reaction is completed, 2g / L hydrochloric acid solution is added to neutralize the pH of the solution to 6.5, and then 2g / L calcium chloride solution is added, and stirred evenly to make Precipitation occurred, filtered, and the waste liquid was removed, and the filter cake was washed with hot water at 45°C and dried in vacuum. Then, acetone was used as the extractant with a solid-to-liquid ratio of 1:15. After 6 extractions, the extract was collected and distilled under reduced pressure at 45°C to obtain a long-chain fatty alcohol (octacosanol).

[0020] (2) Preparation of spinning solution: L-polylactic acid is selected ...

Embodiment 2

[0026] (1) Preparation of octacosanol: Weigh 300 grams of rice bran wax (produced by Haining Debang Chemical Co., Ltd.) and immerse in 3g / L sodium hydroxide aqueous solution, the quality of rice bran wax (g) and the volume of sodium hydroxide aqueous solution (mL) The bath ratio is 1:25, and the reaction is continuously stirred at 96°C for 12 hours. After the reaction is completed, 3g / L hydrochloric acid solution is added to neutralize the pH of the solution to 6.5, and then 3g / L calcium chloride solution is added, and stirred evenly to make Precipitation occurs, filter, remove the waste liquid, then wash the filter cake with hot water at 50°C, and dry it in vacuum. Then, acetone was used as the extractant with a solid-to-liquid ratio of 1:18. After seven times of extraction, the extract was collected and distilled under reduced pressure at 46°C to obtain a long-chain fatty alcohol (octacosanol).

[0027] (2) Preparation of spinning solution: L-polylactic acid is selected as p...

Embodiment 3

[0033] (1) Preparation of octacosanol: Weigh 300 grams of rice bran wax (produced by Haining Debang Chemical Co., Ltd.) and immerse in 4g / L sodium hydroxide aqueous solution, the quality of rice bran wax (g) and the volume of sodium hydroxide aqueous solution (mL) The bath ratio is 1:28, and the reaction is continuously stirred at 95°C for 14 hours. After the reaction is completed, 4g / L hydrochloric acid solution is added to neutralize the pH of the solution to 6.8, and then 4g / L calcium chloride solution is added, and stirred evenly to make Precipitation occurs, filter, remove the waste liquid, then wash the filter cake with hot water at 50°C, and dry it in vacuum. Then, acetone was used as the extractant with a solid-to-liquid ratio of 1:18. After seven times of extraction, the extract was collected and distilled under reduced pressure at 46°C to obtain a long-chain fatty alcohol (octacosanol).

[0034] (2) Preparation of spinning solution: L-polylactic acid is selected as p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com