A kind of preparation method of superhydrophobic lyocell fiber

A fiber and super-hydrophobic technology, applied in the field of preparation of super-hydrophobic lyocell fibers, can solve the problems of high equipment requirements and complex preparation process, and achieve the effects of strong super-hydrophobicity, simple production process and little environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

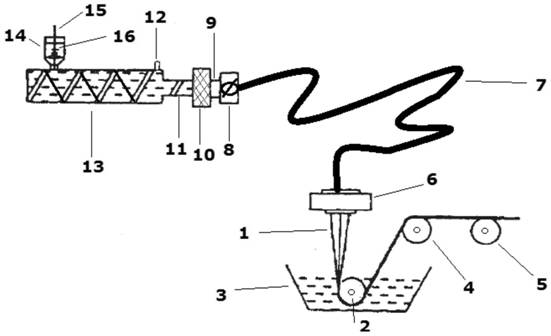

Image

Examples

Embodiment 1

[0021] (1) Preparation of low surface energy substances: Weigh 200 grams of rice bran wax (produced by Haining Debang Chemical Co., Ltd.) and immerse in 1g / L sodium hydroxide aqueous solution, the quality of rice bran wax (g) and the volume of sodium hydroxide aqueous solution (mL) The bath ratio is 1:30, and the reaction is continuously stirred at 90°C for 15 hours. After the reaction is completed, 1g / L hydrochloric acid solution is added to neutralize the pH of the solution to 6, and then 1g / L calcium chloride solution is added, and stirred evenly to make Precipitation occurs, filter, remove the waste liquid, then wash the filter cake with hot water at 40°C, and dry it in vacuum. Then, acetone was used as the extractant with a solid-to-liquid ratio of 1:10. After five extractions, the extract was collected and distilled under reduced pressure at 40°C to obtain long-chain fatty alcohols.

[0022] (2) Preparation of spinning solution: the aqueous solution of NMMO with a mass f...

Embodiment 2

[0030] (1) Preparation of low surface energy substances: Weigh 200 grams of rice bran wax (produced by Haining Debang Chemical Co., Ltd.) and immerse in 2g / L sodium hydroxide aqueous solution, the mass of rice bran wax (g) and the volume of sodium hydroxide aqueous solution (mL) The bath ratio is 1:35, and the reaction is continuously stirred at 95°C for 18 hours. After the reaction is completed, 2g / L hydrochloric acid solution is added to neutralize the pH of the solution to 6.5, and then 2g / L calcium chloride solution is added and stirred evenly to make Precipitation occurred, filtered, and the waste liquid was removed, and the filter cake was washed with hot water at 45°C and dried in vacuum. Then, acetone was used as the extractant with a solid-to-liquid ratio of 1:15. After 6 extractions, the extract was collected and distilled under reduced pressure at 45°C to obtain long-chain fatty alcohols.

[0031] (2) Preparation of spinning solution: the aqueous solution of 54.3% N...

Embodiment 3

[0039] (1) Preparation of low surface energy substances: Weigh 200 grams of rice bran wax (produced by Haining Debang Chemical Co., Ltd.) and immerse in 3g / L sodium hydroxide aqueous solution, the mass of rice bran wax (g) and the volume of sodium hydroxide aqueous solution (mL) The bath ratio is 1:35, and the reaction is continuously stirred at 95°C for 18 hours. After the reaction is completed, 3g / L hydrochloric acid solution is added to neutralize the pH of the solution to 6.5, and then 3g / L calcium chloride solution is added, and stirred evenly to make Precipitation occurred, filtered, and the waste liquid was removed, and the filter cake was washed with hot water at 45°C and dried in vacuum. Then, acetone was used as the extractant with a solid-to-liquid ratio of 1:15. After 7 extractions, the extract was collected and distilled under reduced pressure at 45°C to obtain long-chain fatty alcohols.

[0040] (2) Preparation of spinning solution: the aqueous solution of 52.7% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com