IOT-based industrial control system

An industrial control system and Internet of Things technology, applied in transmission systems, impedance networks, transmitter monitoring, etc., can solve problems such as network delay, signal transmission disorder, and work performance not as good as highly intelligent control systems, so as to prevent signal disorder Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

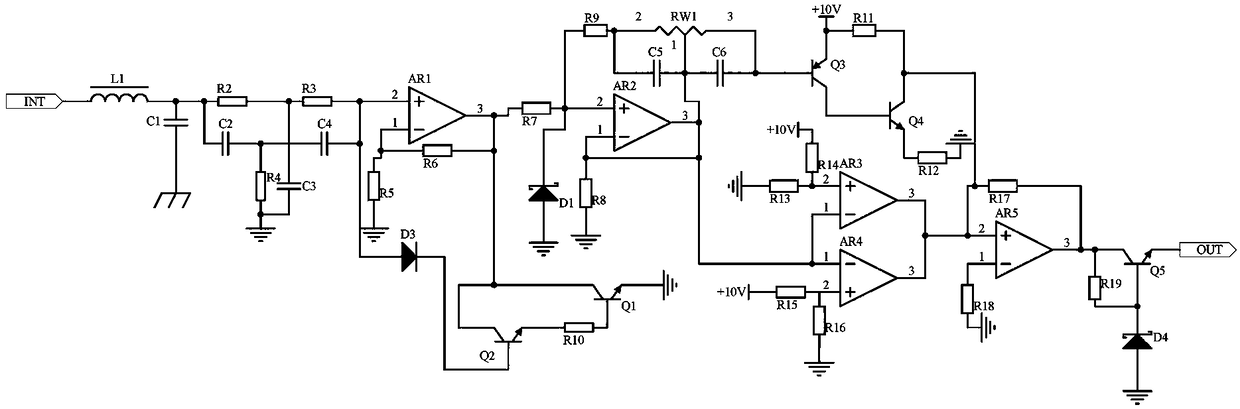

[0014] Embodiment 1, an industrial control system based on the Internet of Things, including a signal receiving circuit, a signal calibration circuit and a voltage-stabilizing output circuit, the signal receiving circuit receives the input of the signal transmission channel for the control terminal in the industrial control system based on the Internet of Things The signal is filtered by the LC filter circuit composed of inductor L1 and capacitor C1 to filter out high-frequency interference, and then enters the double T frequency selection circuit composed of resistors R2~R4 and capacitors C2~C4 to filter out the single frequency signal in the signal, and the signal is calibrated The circuit is divided into two ways to receive the signal and receive the output signal of the circuit. One way uses the composite circuit composed of the triode Q1 and the triode Q2 to detect the abnormally high level signal, and discharges the abnormally high level signal to the ground. The second wa...

Embodiment 2

[0017] Embodiment 2, on the basis of Embodiment 1, the signal receiving circuit receives the signal at the input end of the signal transmission channel for the control terminal in the industrial control system based on the Internet of Things, and filters high Frequency interference, improve the anti-interference of the signal, and prevent the interference signal from affecting the calibration effect of the signal calibration circuit, and then enter the double T frequency selection circuit composed of resistors R2~R4 and capacitors C2~C4 to filter out the single frequency signal in the signal, Only a single frequency signal can be calibrated by the signal calibration circuit. Different frequency signal calibration can easily cause signal disturbance. One end of the inductance L1 is connected to the signal input port, and the other end of the inductance L1 is connected to one end of the resistor R2, capacitor C1, and capacitor C2. The other end of capacitor C1 is grounded, the ot...

Embodiment 3

[0018]Embodiment 3, on the basis of Embodiment 1, the voltage-stabilizing output circuit uses the op-amp AR5 to amplify in phase and output after the voltage-stabilizing circuit composed of the triode Q5 and the voltage-stabilizing tube D4 stabilizes the voltage, thereby improving the stability of the signal. That is to say, in the control terminal signal transmission channel of the industrial control system based on the Internet of Things, the non-inverting input terminal of the operational amplifier AR5 is connected to the collector of the transistor Q4 and one end of the resistor R17, and the inverting input terminal of the operational amplifier AR5 is connected to the resistor One end of R18, the other end of resistor R18 is grounded, the output terminal of op amp AR5 is connected to the other end of resistor R17, one end of resistor R19, the collector of transistor Q5, and the other end of resistor R19 is connected to the base of transistor Q5 and the regulator The negativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com