Packaging film and application thereof

A technology for encapsulating thin films and forming films, which is applied in the direction of electrical components, circuits, and electric solid devices, etc., can solve the problems of unsatisfactory packaging film layer stability, poor performance stability of electronic devices, and poor barrier ability, etc., to achieve the stability of inorganic substances Good, good compactness, increase the effect of interface adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

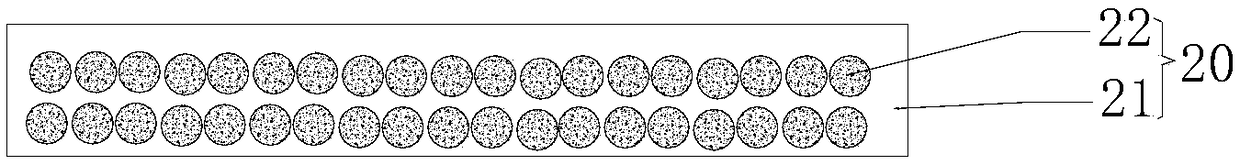

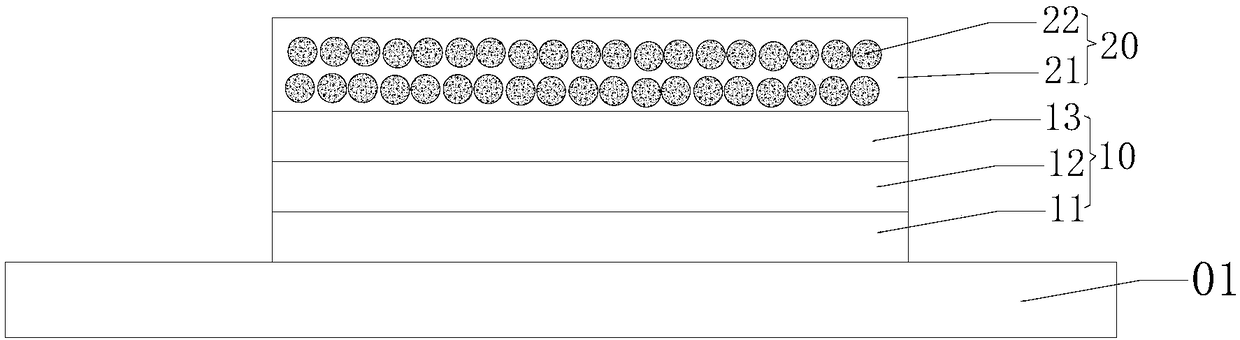

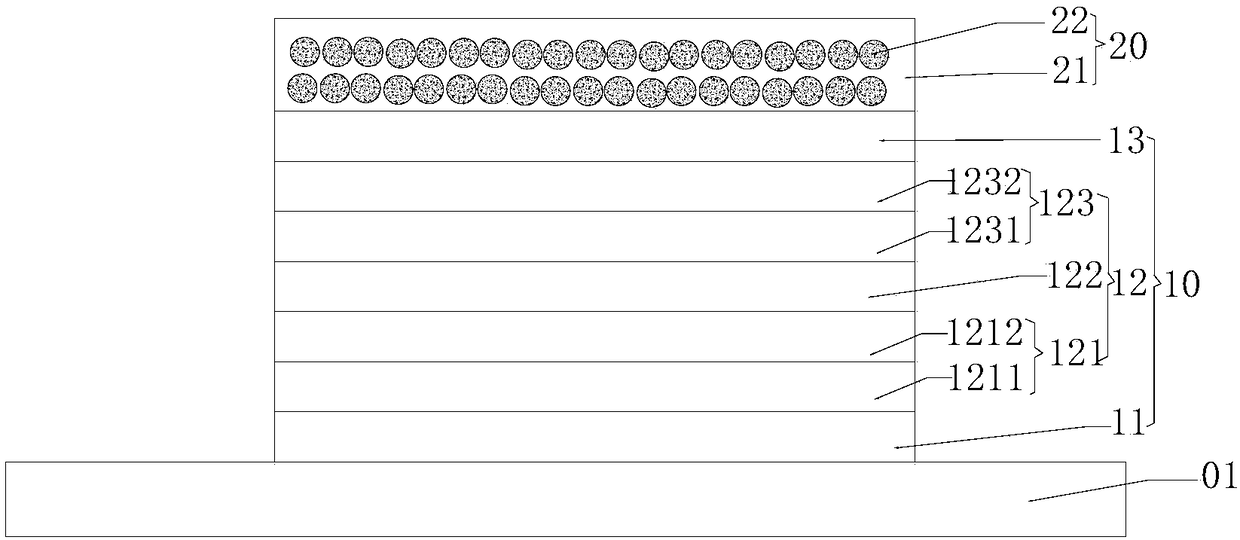

[0062] In another aspect, an embodiment of the present invention provides a method for manufacturing the electronic device. Combine Figure 1-3 , The manufacturing method of the electronic device includes the following steps:

[0063] Providing a substrate, the substrate including a substrate 01 and an electronic component 10 disposed on the substrate;

[0064] The packaging film 20 is formed on the substrate to encapsulate the electronic components.

[0065] The term "encapsulation" used in the present invention refers to the use of an encapsulation film to cover the parts of the electronic components that need to be encapsulated. According to the realized characteristics or work needs, different electronic component 10 structures have different requirements for the encapsulated parts. Specifically, The portion of the electronic component 10 that needs to be packaged can be all the top surfaces and sides of the electronic component, or of course, it can also be only the top surfac...

Embodiment 1

[0085] This embodiment provides an electronic device. It includes a substrate, a QLED electronic component bonded on the substrate, and a packaging film for packaging the QLED electronic component. The structure of the electronic device is: ITO substrate / PEDOT:PSS (50nm) / poly-TPD (30nm) / quantum dot light-emitting layer (20nm) / ZnO (30nm) / silver (70nm) / encapsulation film (700nm). Wherein, the material of the packaging film is SiO 2 Nanoparticles and polysiloxane composite, the SiO 2 Nano particles are dispersed in polysiloxane, and SiO 2 Nanoparticles are 1.5% of the mass of the packaging film, and the thickness of the packaging film is 700 nm.

[0086] The electronic device of this embodiment is prepared according to the following method:

[0087] S11: The layers are sequentially formed on the ITO substrate according to the QLED structure of this embodiment to form a QLED;

[0088] S12: Screen printing is used to form a packaging film on the top surface of the silver electrode of th...

Embodiment 2

[0093] This embodiment provides an electronic device. It includes a substrate, a QLED electronic component bonded on the substrate, and a packaging film for packaging the QLED electronic component. The structure of the electronic device is: ITO substrate / PEDOT:PSS (50nm) / poly-TPD (30nm) / quantum dot light-emitting layer (20nm) / ZnO (30nm) / silver (70nm) / encapsulation film (1000nm). Wherein, the material of the packaging film is SiO 2 Nanoparticles and polysiloxane composite, the SiO 2 Nano particles are dispersed in PTFE, and SiO 2 The nanoparticles account for 4.8% of the mass of the packaging film, and the thickness of the packaging film is 1000 nm.

[0094] The preparation method can refer to the method in Example 1, only need to adjust the SiO in the colloid 2 The content of squeegee should be adjusted, and the value of the squeegee pressure should be about 110N / m, the squeegee angle should be 60°, the curing temperature should be 120°C, and the curing time should be 40min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com