Vertical superconducting pyrogasification furnace for garbage

A technology of pyrolysis gasification and superconductivity, which is applied in the direction of gasification process, manufacture of combustible gas, petroleum industry, etc. It can solve the problems of non-continuous operation, large diameter, large ash residue, etc., to prevent generation and discharge, and shield secondary Great effect of reducing pollution and garbage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] specific implementation plan

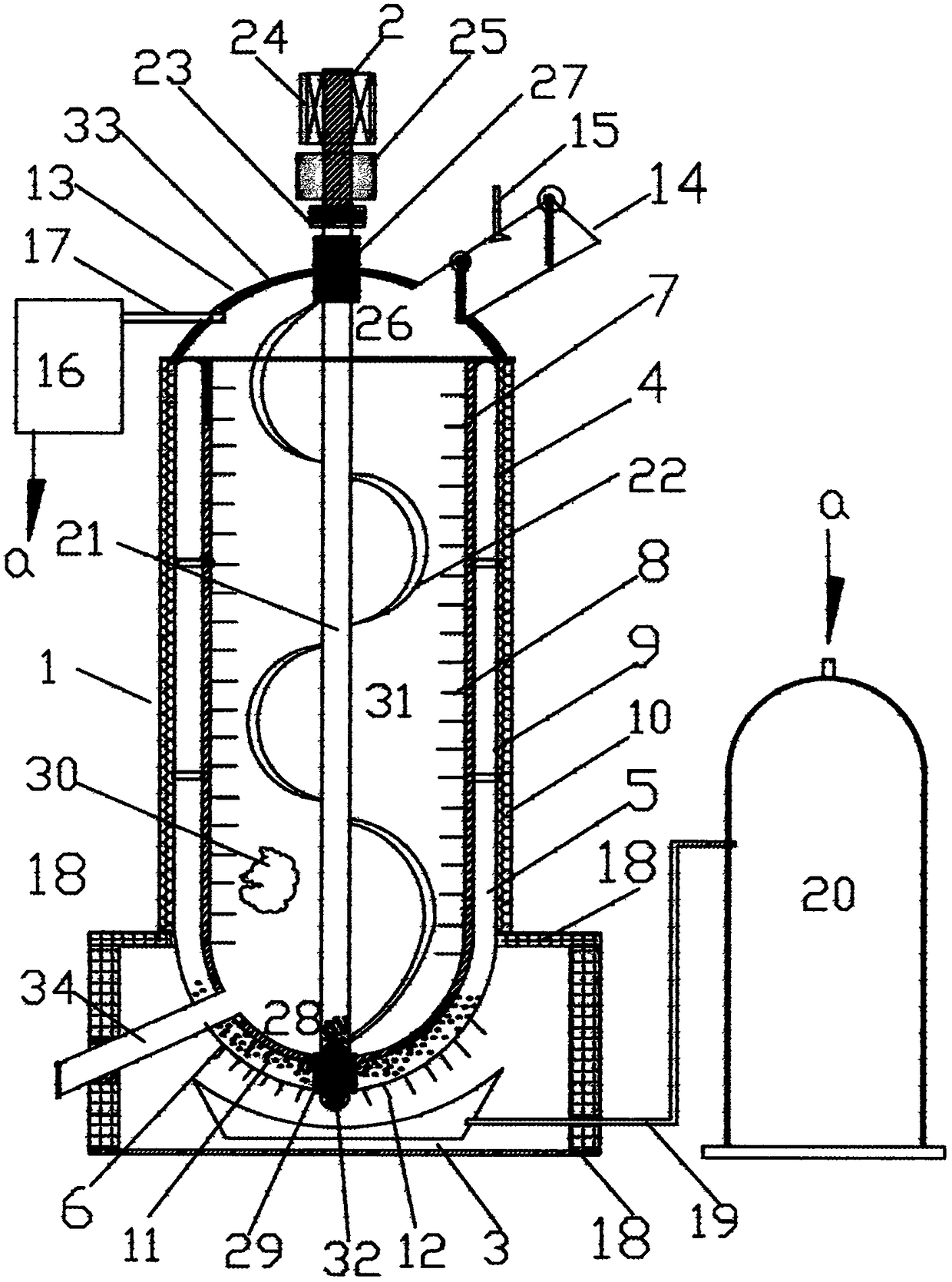

[0021]A vertical superconducting waste pyrolysis gasification furnace is composed of a double-layer tube furnace body 1, a superconducting stirrer 2 and a burner 3. It is characterized in that the double-layer tube furnace body 1 is a double-layer cylinder 4 in which two circular tubes are sheathed together, a circumferential superconducting cavity 5 is formed between the two layers of the double-layer cylinder 4, and the lower end of the double-layer cylinder 4 is a double-layer The round head 6, the double-layer round head 6 is connected with the double-layer cylinder 4 to form a cup-shaped superconductor, the circumferential superconducting cavity 5 of the cup-shaped superconductor is equipped with a number of cooling fins 8 on the inner tube wall 7, and the outer tube wall 9 is wrapped Pack high temperature resistant insulation layer 10. A high-temperature superconducting working medium 11 is installed in the double-layer round head 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com