Etchant composition, and method of producing metal pattern and thin film transistor substrate using the same

A technology of composition and etchant, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., and can solve problems such as poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

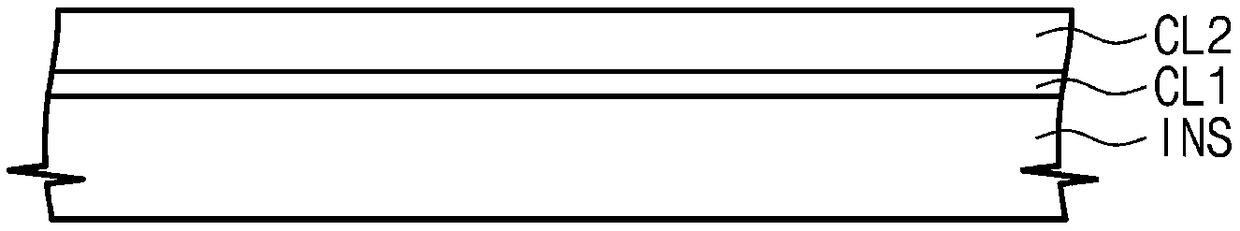

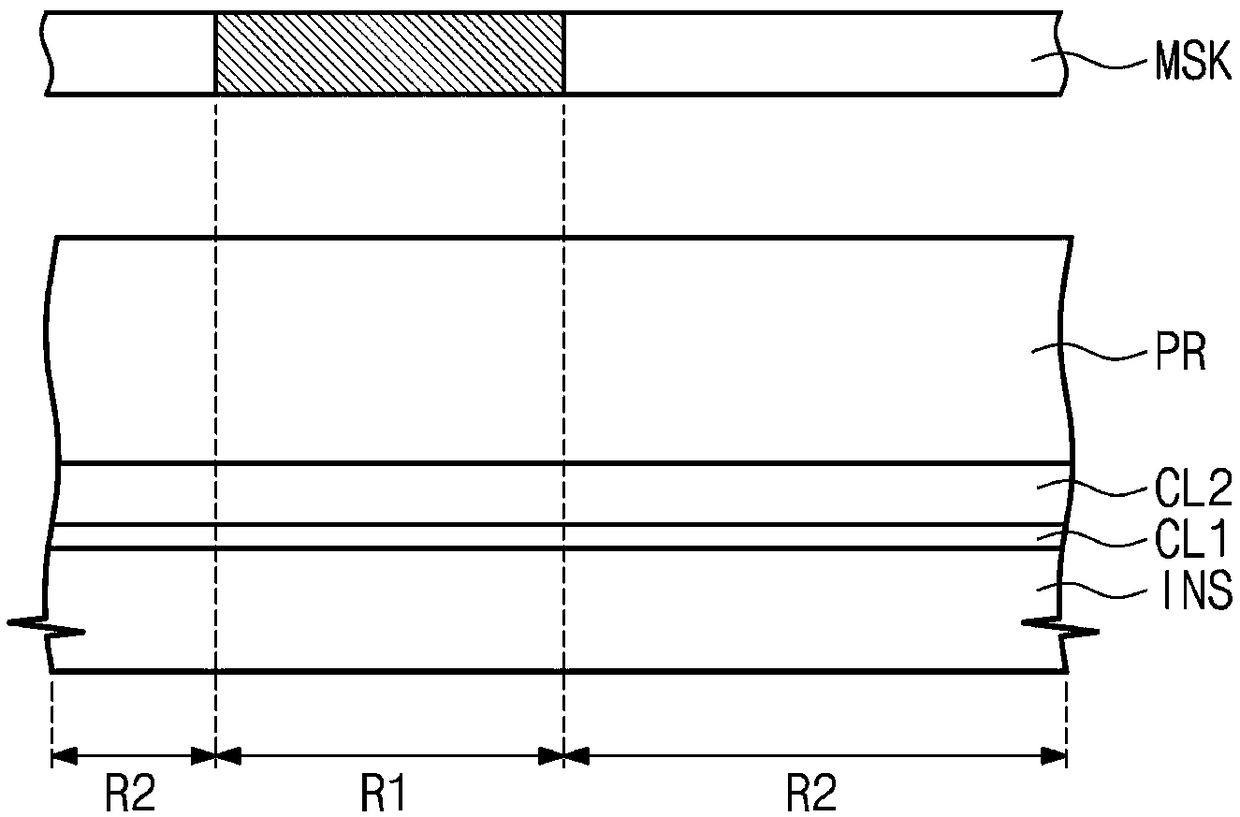

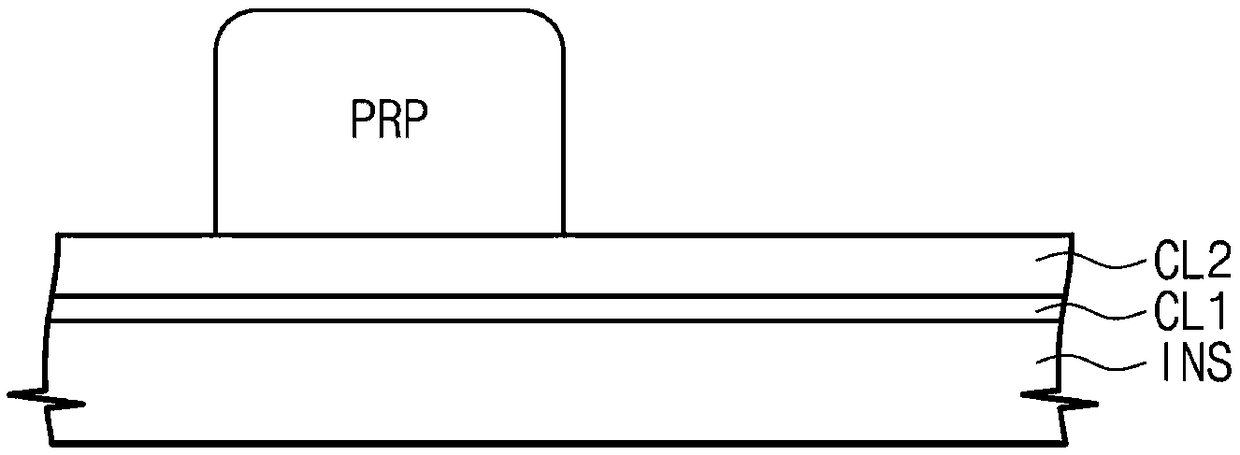

[0030] Hereinafter, embodiments of the inventive concept will be described with reference to the accompanying drawings. In this specification, when an element (or region, layer, portion, etc.) is referred to as being "on," "connected to," or "coupled to" another element, it means that the element is directly connected / coupled to another element, or a third element may be disposed therebetween.

[0031] Like reference numerals refer to like elements. Also, in the drawings, the thickness, proportions, and dimensions of elements are exaggerated for effective description of their technical contexts. "And / or" includes all of one or more combinations that may be defined by the relevant configuration.

[0032] It will be understood that, although the terms first, second etc. may be used herein to describe various elements, these elements should not be limited by these terms. These terms are only used to distinguish one element from another. For example, a first element could be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com