Liquid pressure alternating pressure pump and pressure exchanging method thereof

A liquid pressure, liquid technology, applied in the direction of fluid pressure converter, mechanical equipment, etc., can solve the problems of crankshaft connecting rod structure volume and manufacturing cost, it is difficult to move the piston with large stroke, reduce the motor power output, and limit the unit recovery amount. , to achieve the effect of novel and flexible energy exchange method, increase the amount of liquid injected, and reduce energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

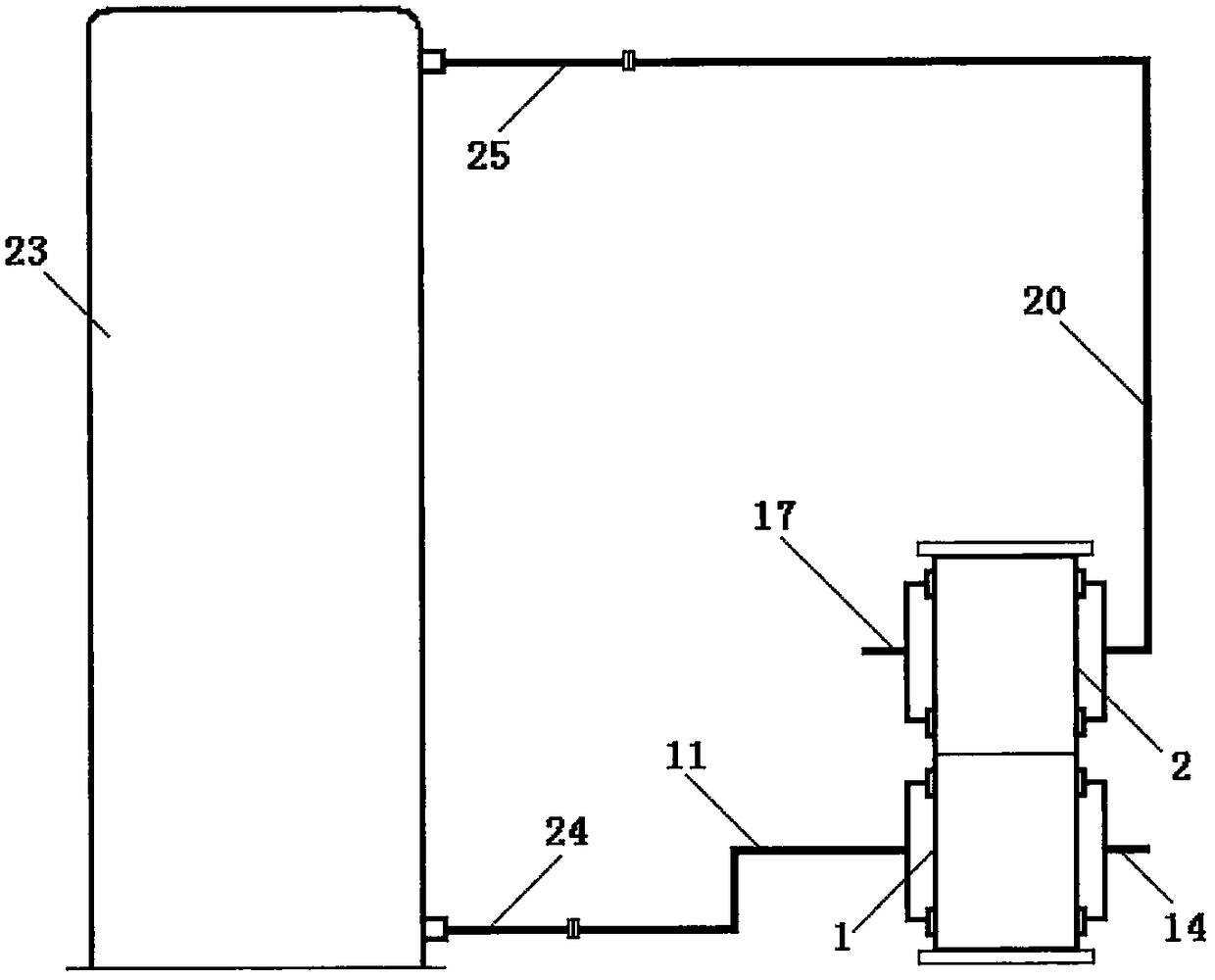

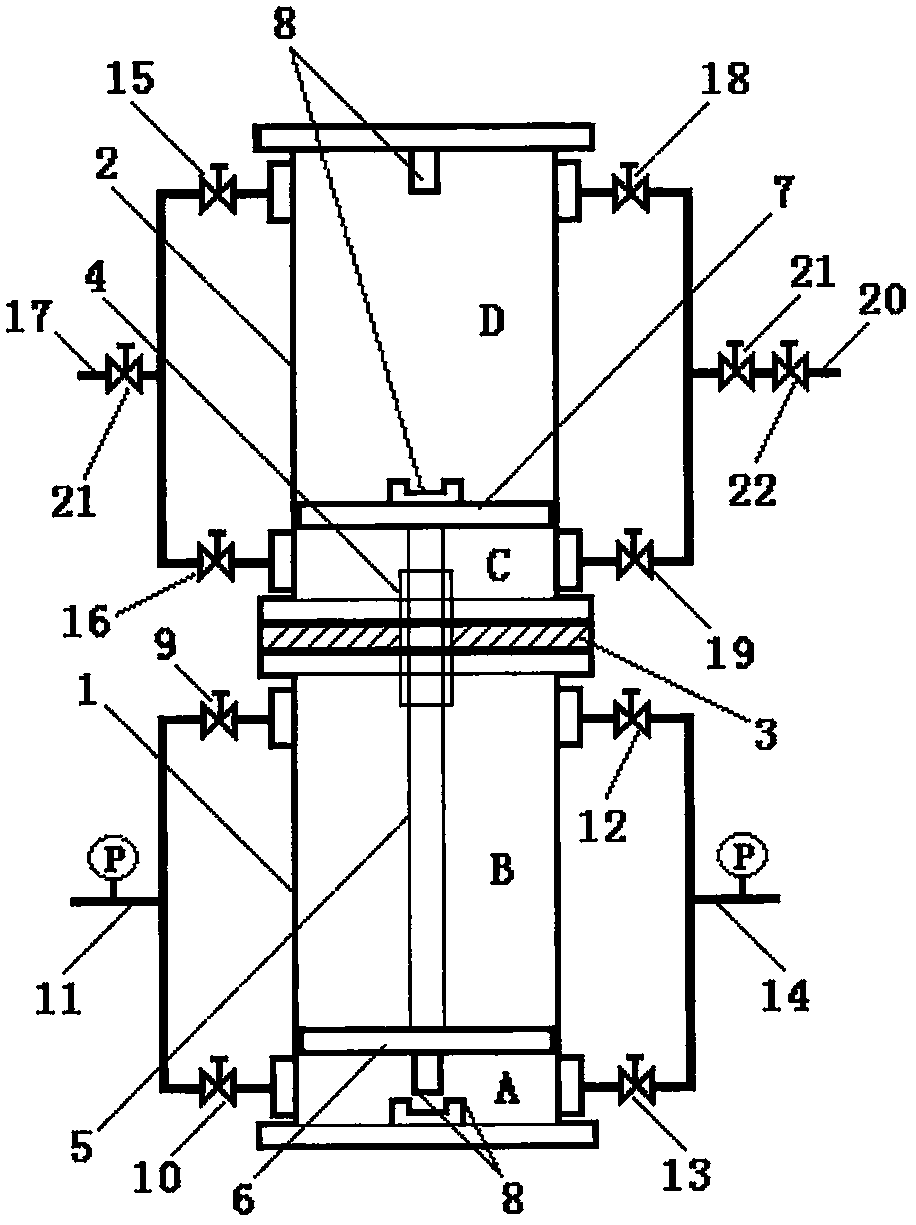

[0027] Embodiment one: if figure 1 , 2 As shown, taking the pipeline connecting the self-operated liquid pressure alternating pressure pump to the high-pressure washing tower 23 as an example, the power cylinder 1 is connected to the liquid outlet pipe 24 of the high-pressure washing tower 23 through the power liquid inlet main pipe 11, and the power liquid discharge main pipe 14 goes to To the next process; the pump liquid cylinder body 2 is connected to the upper liquid pipe 25 of the high-pressure washing tower 23 through the pump liquid discharge main pipe 20, and the pump liquid inlet main pipe 17 is connected to the solvent storage tank.

[0028] The pressure exchange method of the self-operated liquid pressure alternating pressure pump comprises the following steps:

[0029] a. When the power piston 6 and the pump liquid piston 7 are at the bottom of the stroke, the power lower liquid inlet valve 10 is opened, and at the same time the power upper liquid discharge valve...

Embodiment 2

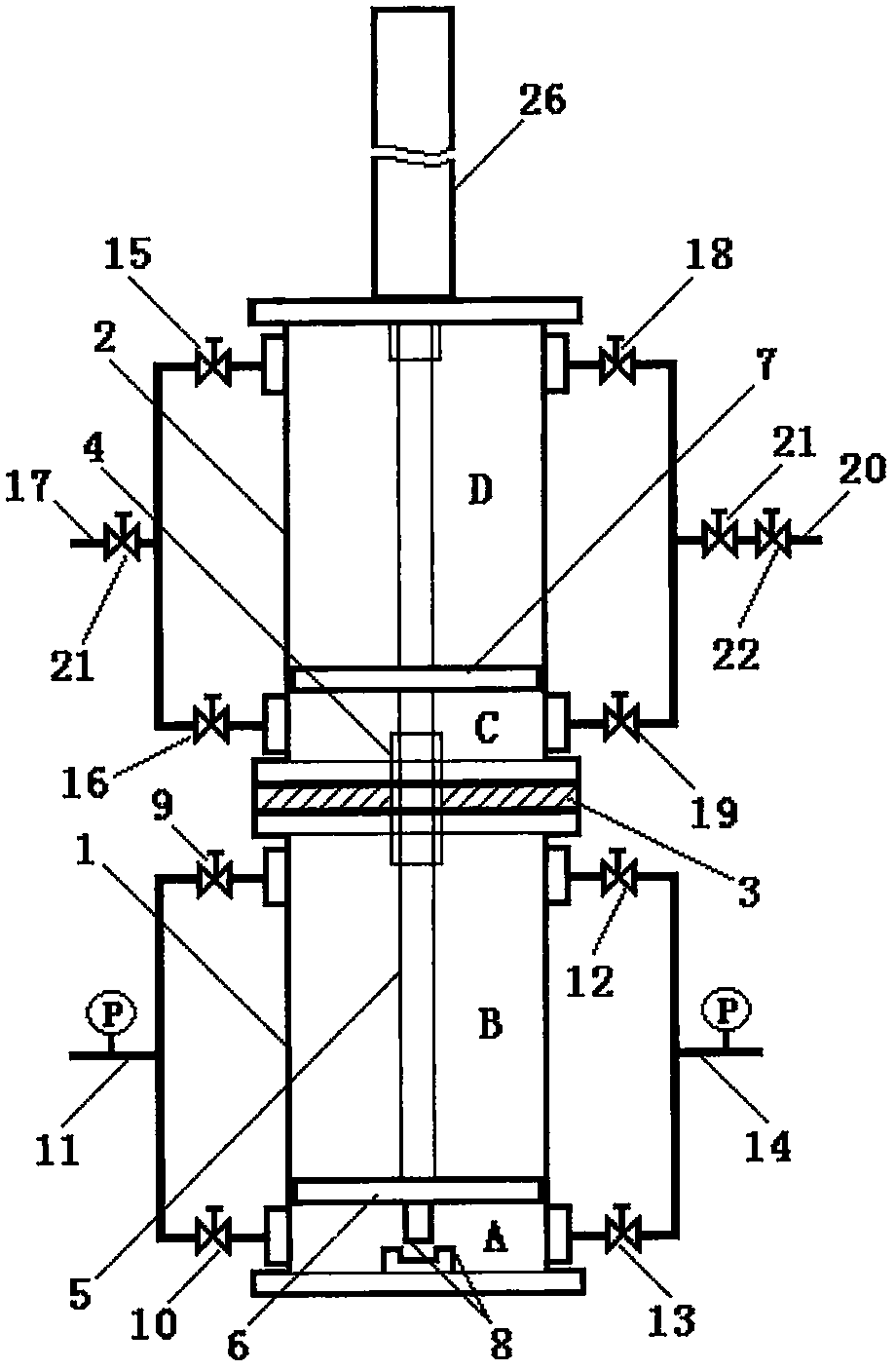

[0033] Embodiment two: if image 3 As shown, the power-assisted liquid pressure alternating pressure pump can be applied under special conditions, and its working principle is basically the same as that of the self-powered liquid pressure alternating pressure pump. There is a power-assisted hydraulic cylinder 26, and the upper end of the piston rod 5 is extended, which is also the piston rod of the power-assisted hydraulic cylinder. The power-assisted hydraulic cylinder 26 can assist the automatic operation of the two pistons under the timing control of the system, increasing the volume of pumping fluid and improving energy efficiency. Recovery rate, easy to control the operation of the pump.

[0034] The invention can work with a single pump or in groups. When the liquid exchange volume is large, the groups operate in a time-series network, and are especially suitable for application in modern large-scale industrial production processes.

[0035] Considering the economy, thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com