Flexible photoinduced ultrasonic film transducer and its preparation method

A technology of photoinduced ultrasound and transducers, which is applied in the direction of fluid using vibration, etc., can solve problems such as poor coupling and ultrasonic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

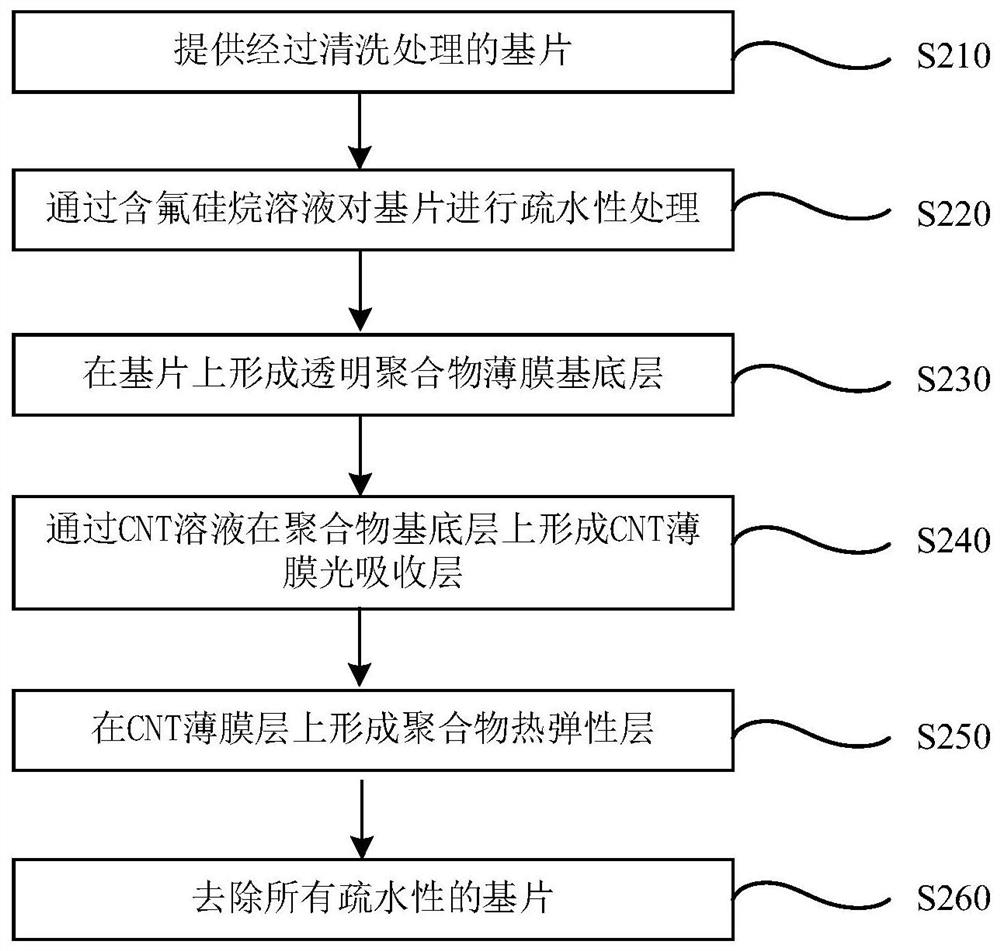

[0048] Such as figure 2 As shown, the steps of the present invention to prepare the flexible photo-ultrasonic thin film transducer Example 1 are as follows.

[0049] 1. Step S210, providing a cleaned glass substrate.

[0050] The glass substrate is treated with vacuum plasma to remove organic impurities on the glass surface and increase surface wettability. The substrate provided in this step can be but not limited to glass.

[0051] Among them, the vacuum plasma treatment time is 300s.

[0052] 2. Step S220, using a fluorine-containing silane solution to perform hydrophobic treatment on the substrate.

[0053] Soak the substrate cleaned in step S210 in the fluorine-containing silane solution, take out the substrate after a period of time, and then rinse and dry it. It is also possible to form a substrate with a hydrophobic surface based on a fluorine-containing silane solution and using methods such as spin coating, solution spraying, solution evaporation, and the like. ...

Embodiment 2

[0068] 1. Step S210, providing a cleaned glass substrate.

[0069] The supplied substrates are vacuum plasma treated to remove organic impurities from the glass surface and increase surface wettability. The substrate provided in this step can be but not limited to glass.

[0070] Among them, the vacuum plasma treatment time is 300s.

[0071] 2. Step S220, using a fluorine-containing silane solution to perform hydrophobic treatment on the substrate.

[0072] Soak the substrate cleaned in step S210 in the fluorine-containing silane solution, take out the substrate after a period of time, and then rinse and dry it. It is also possible to form a substrate with a hydrophobic surface based on a fluorine-containing silane solution and using methods such as spin coating, solution spraying, solution evaporation, and the like.

[0073] The fluorine-containing silane solution in this embodiment is a mixed solution of tridecafluorooctyltrimethoxysilane and toluene, and the concentratio...

Embodiment 3

[0086] The fluorine-containing silane solution used in this embodiment is a mixture of dodecafluoroheptylpropyltrimethoxysilane and toluene, wherein the concentration of fluorine-containing silane is 10 vol%.

[0087] Specifically, the steps are as follows:

[0088] 1. Step S210, providing a cleaned glass substrate.

[0089] The supplied substrates are vacuum plasma treated to remove organic impurities from the glass surface and increase surface wettability. The substrate provided in this step can be but not limited to glass.

[0090] Among them, the vacuum plasma treatment time is 300s.

[0091] 2. Step S220, using a fluorine-containing silane solution to perform hydrophobic treatment on the substrate.

[0092] Soak the substrate cleaned in step S210 in the fluorine-containing silane solution, take out the substrate after a period of time, and then rinse and dry it. It is also possible to form a substrate with a hydrophobic surface based on a fluorine-containing silane so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com