Multilayer coextrusion packaging film with paper hand feeling and preparation method of multilayer coextrusion packaging film

A multi-layer co-extrusion and packaging film technology, applied in the field of packaging materials, can solve the problems of discoloration, non-waterproof, and affecting the sensory effect of packaging paper, etc., and achieve the effect of color change and color adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

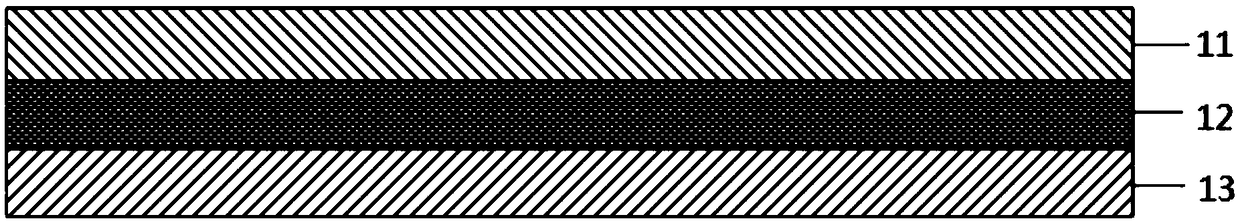

[0047] The multi-layer co-extruded packaging film with papery feel with a thickness of 60 microns is prepared, comprising the following steps:

[0048] For the surface layer 11, 60 parts of LLDPE with a melt index of 1.5-2.4, 35 parts of yellow resin containing imitation paper particles, and 5 parts of biodegradation agent are added to the hopper 1 of the extruder, melted at a temperature of 200 ° C, and enter Die;

[0049] For the middle layer 12, 90 parts of LLDPE with a melt index of 1.5-2.4 and 10 parts of biodegradation agent are added to the hopper 2 of the extruder, melted at a temperature of 200°C, and enter the die;

[0050] In the inner layer 13, 60 parts of LLDPE with a melt index of 1.5-2.4, 35 parts of yellow resin containing imitation paper particles, and 5 parts of biodegradation agent are added to the hopper 3 of the extruder, and melted at a temperature of 200 ° C. into the die;

[0051] The tubular film extruded through the multi-layer die head and the die ...

Embodiment 2

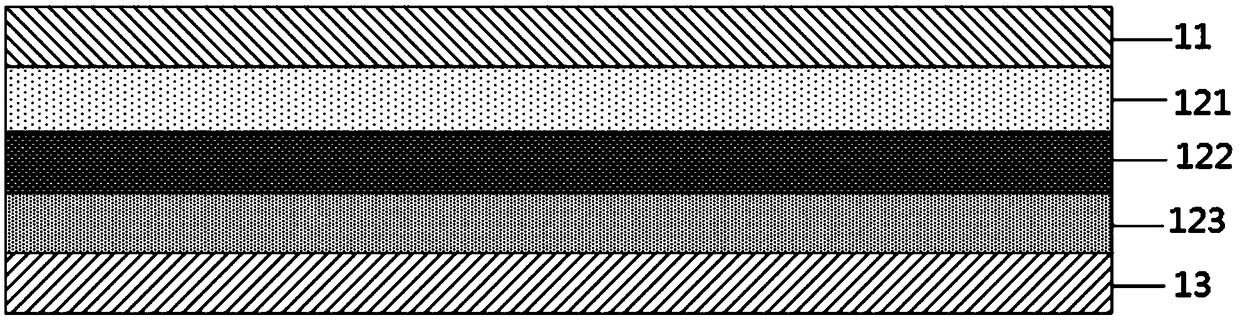

[0056] The multi-layer co-extruded packaging film with papery feel that the preparation thickness is 100 microns comprises the following steps (feeding according to consumption in Table 1):

[0057] For the surface layer 11, LLDPE, yellow resin containing imitation paper particles, and biodegradation agent are added to the hopper 1 of the extruder, melted at a temperature of 200°C, and enter the die;

[0058]For the middle layer 12, ethylene copolymer and biodegradation agent are added to the hopper 2 of the extruder, melted at a temperature of 170°C, and enter the die;

[0059] For the inner layer 13, LLDPE, yellow resin containing imitation paper particles, and biodegradation agent are added to the hopper 3 of the extruder, melted at a temperature of 200°C, and enter the die;

[0060] Other steps are with embodiment 1.

Embodiment 3

[0062] The multi-layer co-extruded packaging film with papery feel that the preparation thickness is 100 microns comprises the following steps (feeding according to consumption in Table 1):

[0063] For the surface layer 11, LLDPE, yellow resin containing imitation paper particles, and biodegradation agent are added to the hopper 1 of the extruder, melted at a temperature of 200°C, and enter the die;

[0064] For the middle layer 12, ethylene copolymer and biodegradation agent are added to the hopper 2 of the extruder, melted at a temperature of 170°C, and enter the die;

[0065] In the inner layer 13, LLDPE, yellow resin containing imitation paper particles, and biodegradation agent are added to the hopper 3 of the extruder, melted at a temperature of 200°C, and enter the die;

[0066] Other steps are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap