Preparation method of mesoporous metal composite oxide nanomaterial with adjustable aperture

A technology of metal composites and nanomaterials, applied in chemical instruments and methods, manganese compounds, cobalt compounds, etc., can solve the problems of restricting widespread use and complicated process flow, and achieve the goal of easy operation, cheap and easy-to-obtain raw materials, and wide application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

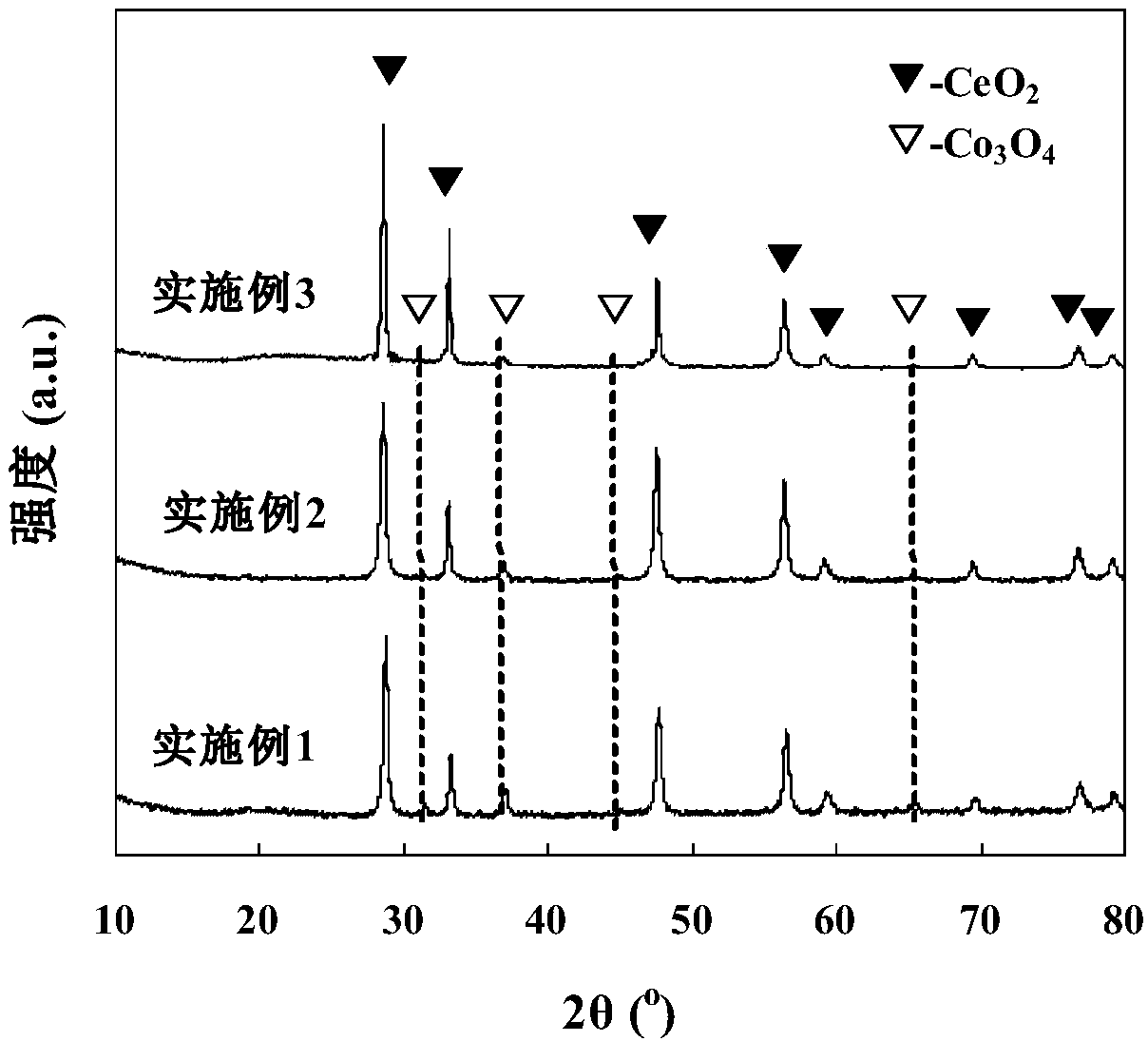

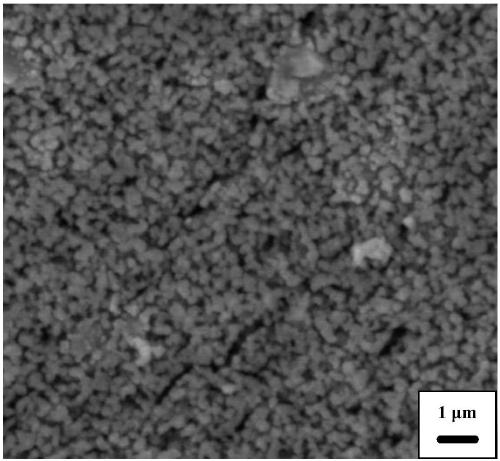

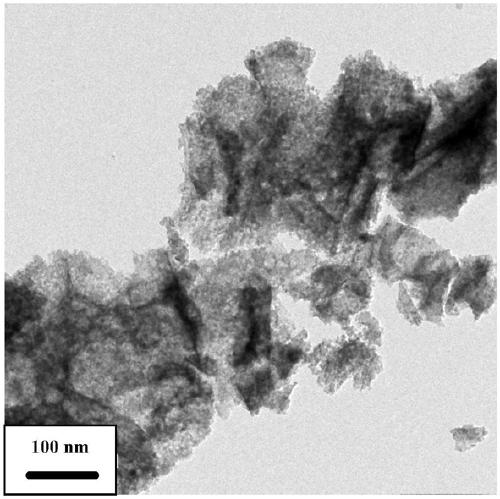

Embodiment 1

[0035] Grind cerium nitrate, cobalt nitrate, and citric acid separately to fine powder, then mix and grind them in a certain proportion for 30 minutes to obtain a very fine powder precursor, spread the precursor evenly in a crucible, and put it into a tubular high-temperature furnace Inside, 15 ml / min of air was introduced, and the temperature was raised to 120 °C at a heating rate of 1 °C / min and kept for 100 minutes, then continued to be heated at a heating rate of 1 °C / min to 450 °C and kept for 200 min, and then taken out after natural cooling The samples were washed three times with deionized water and absolute ethanol, and then dried in an oven at 60 °C for 100 minutes to obtain mesoporous CeCoO x Composite oxide nanoparticles are denoted as A2. The specific surface area and average pore diameter are 145 m 2 / g and 9.0 nm. Wherein the molar ratio of cerium nitrate, cobalt nitrate and citric acid used is 1:1:2 successively.

Embodiment 2

[0037] Mesoporous CeCoO was prepared according to the method of Example 1 x Composite oxide nanomaterials, denoted as A4, have a specific surface area and an average pore diameter of 163 m 2 / g and 8.4 nm. The difference is that the molar ratio of cerium nitrate, cobalt nitrate and citric acid used is 1:1:8 in sequence; the burning temperature is 500°C.

Embodiment 3

[0039] Mesoporous CeCoO was prepared according to the method of Example 1x Composite oxide nanomaterials, denoted as A5, have a specific surface area and an average pore diameter of 150 m 2 / g and 7.7 nm. The difference is that the selected burning atmosphere is nitrogen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com