Method for producing acidic potassium dihydrogen phosphate

A technology of acid potassium dihydrogen phosphate and phosphoric acid, applied in ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, phosphate fertilizer, etc., can solve the problems of high cost and low purity of acid potassium dihydrogen phosphate, and reduce cooling The effect of water consumption, high purity and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

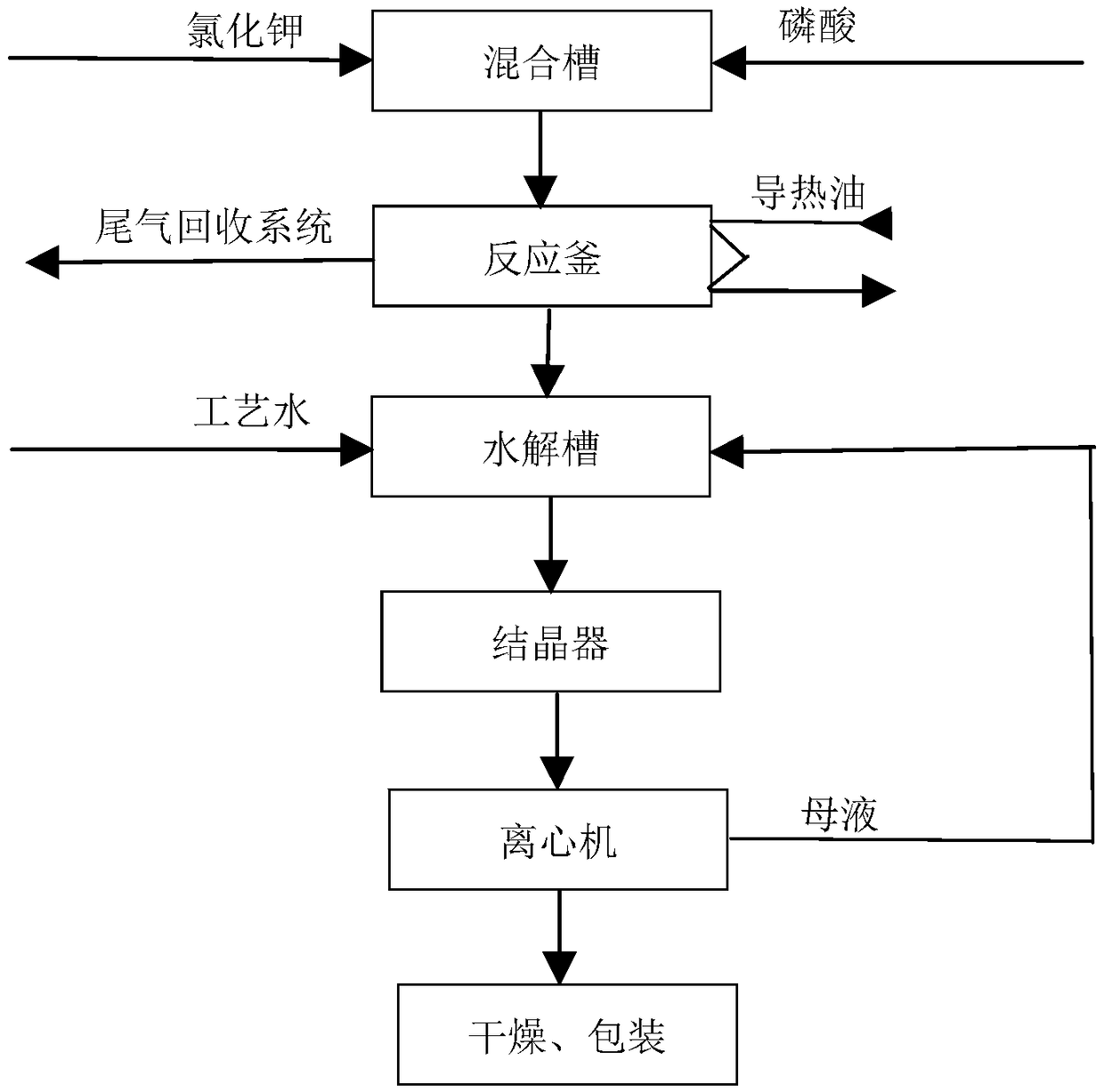

Image

Examples

Embodiment 1

[0050] First, take P 2 o 5 Add 1500g of purified phosphoric acid with a concentration of 42% into a 2000ml beaker and stir, press H 3 PO 4 : KCl molar ratio 2.1:1 calculation adding K 2 325g of industrial potassium chloride with an O content of 61.04% is mixed in a beaker; secondly, the dechlorination reaction is carried out by heating in an electric furnace, and the temperature of the slurry reaches 198° C. The slurry is moved to a beaker containing 1265g process water for hydrolysis, and the slurry density after hydrolysis is 1498Kg / m 3 ; The 4th, hydrolysis slurry continues cooling, crystallization, uses Buchner funnel to filter when temperature drops to 28 ℃, obtains crystalline product;figure 1 As shown, the finished product inspection data are shown in Table 1, wherein the pH value uses a pH meter to detect 4‰ of the finished product aqueous solution. The G4 crucible of the water-insoluble product in this embodiment is detected at 0.09%-0.3%, and the water-insoluble ...

Embodiment 2

[0054] First, take P 2 o 5 Add 1500g of industrial phosphoric acid with a concentration of 54.4% into a 2000ml beaker and stir, press H 3 PO 4 : KCl molar ratio of 1.9:1 calculated by adding K 2 466g of industrial potassium chloride with an O content of 61.04% is mixed in a beaker; second, the electric furnace is heated to carry out dechlorination reaction, and the slurry temperature reaches 229 ° C. The reaction ends, and the process control pressure is 99.6KPa; the third, the dechlorination slurry Move to the beaker that contains 1563g process water and carry out hydrolysis, the slurry density after hydrolysis is 1598Kg / m 3 Fourth, the hydrolyzed slurry continues to cool and crystallize, and when the temperature drops to 47°C, use a Buchner funnel to filter to obtain a crystallized product; fifth, the product is dried in a vacuum oven to obtain 816g of finished product, and the test data of the finished product are shown in the table below, wherein The PH value uses a pH...

Embodiment 3

[0058] according to figure 2 The process shown in the scale-up test, first, use our company's P 2 o 5 120Kg of purified phosphoric acid with a concentration of 24.3%, press H 3 PO 4 : KCl molar ratio 2:1 calculation adding K 2 15.9Kg of industrial potassium chloride with an O content of 60.7% is mixed in a mixing tank; secondly, the slurry is transferred to a reactor and heated with heat conduction oil for dechlorination reaction, first controlling the reaction pressure to 60KPa, and then gradually increasing the pressure to 101.5 KPa, the temperature of the slurry reaches 160℃~190℃ to stop the reaction; thirdly, move the dechlorinated slurry to the hydrolysis tank for hydrolysis, add process water, and control the density of the slurry after hydrolysis to 1500Kg / m 3 ~1600Kg / m 3 ; Fourth, the slurry continues to cool and crystallize, and when the temperature drops to 40°C to 45°C, use a centrifuge to filter the crystallized product, and collect the centrifuged mother liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com