Preparation method of natural aromatic sponge with high adsorbing efficiency

A sponge and aromatic technology, applied in the field of preparation of natural aromatic sponges, can solve the problems of safety and environmental protection, and achieve the effects of improving the embedding effect, increasing the adsorption capacity, and prolonging the release time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

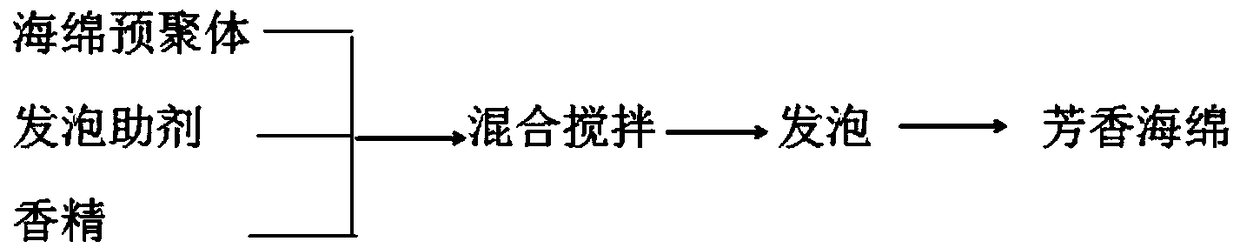

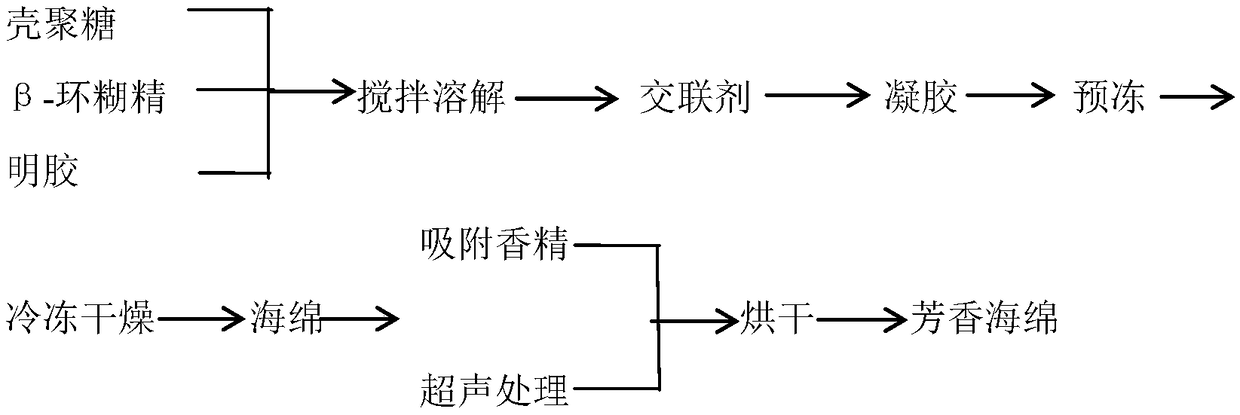

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 0.375g of chitosan, 0.25g of β-cyclodextrin and 0.375g of gelatin in a beaker, the mass ratio of chitosan, β-cyclodextrin and gelatin is 3:2:3, add Concentration is 0.05mol / L acetic acid solution 60ml, stir while adding, and heat to 50 ℃ for 30min, continue to stir overnight, make chitosan, β-cyclodextrin and gelatin dissolve completely, obtain mixed solution.

[0028] (2) Add cross-linking agent glutaraldehyde, the mass fraction is 50% glutaraldehyde aqueous solution dosage is 0.2ml, stir evenly, pour into flat mold, put into oven, 60 ℃ cultivate 2 hours, form gel, put into the refrigerator at 4°C for 8 hours.

[0029] (3) After taking it out, put it in a refrigerator at -20°C for 12 hours, and freeze-dry it at -80°C for 24 hours. Take it out and get a sponge.

[0030] (4) 1ml of clove essence is added in 99ml of ethanol to obtain a concentration of 1% essence solution.

[0031] (5) Cut the obtained sponge into small pieces with a size of 1 cm×1 cm and a m...

Embodiment 2

[0034] (1) Weigh 0.3g of chitosan, 0.4g of β-cyclodextrin and 0.3g of gelatin in a beaker, the mass ratio of chitosan, β-cyclodextrin and gelatin is 3:4:3, add Concentration is 0.05mol / L acetic acid solution 60ml, stir while adding, and heat to 50 ℃ for 30min, continue to stir overnight, make chitosan, β-cyclodextrin and gelatin dissolve completely, obtain mixed solution.

[0035](2) Add crosslinking agent glutaraldehyde, the amount of glutaraldehyde aqueous solution with a mass fraction of 50% is 0.3ml, stir evenly, pour it into a flat mold, put it in an oven, and incubate at 60°C for 2 hours to form a gel, put Refrigerate at 4°C for 8 hours.

[0036] (3) After taking it out, put it in a refrigerator at -20°C for 12 hours, and freeze-dry it at -80°C for 24 hours. Take it out and get a sponge.

[0037] (4) Add 2ml of green tea essence and orange peel essence to 98ml of ethanol at a volume ratio of 1:1 to obtain an essence solution with a concentration of 2%.

[0038] (5) Cu...

Embodiment 3

[0041] (1) Weigh 0.25g of chitosan, 0.5g of β-cyclodextrin and 0.25g of gelatin in a beaker, the mass ratio of chitosan, β-cyclodextrin and gelatin is 1:2:1, add Concentration is 0.1mol / L acetic acid solution 60ml, stir while adding, and heat to 50 ℃ for 30min, continue to stir overnight, make chitosan, β-cyclodextrin and gelatin dissolve completely, obtain the mixed solution.

[0042] (2) Add crosslinking agent glutaraldehyde, the amount of glutaraldehyde aqueous solution with a mass fraction of 50% is 0.4ml, stir evenly, pour it into a flat mold, put it into an oven, and incubate at 60°C for 2 hours to form a gel, put it into Refrigerate at 4°C for 8 hours.

[0043] (3) After taking it out, put it in a refrigerator at -20°C for 12 hours, and freeze-dry it at -80°C for 24 hours. Take it out and get a sponge.

[0044] (4) Add 3ml of clove essence, orange peel essence and lemon essence to 97ml of ethanol at a volume ratio of 1:1:1 to obtain a 3% essence solution.

[0045] (5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com