Silane crosslinked polyethylene insulating material for heating cable and preparation method and application thereof

A polyethylene insulation and heating cable technology, applied in insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problems of unsatisfactory heating cables, and the temperature resistance level is only about 90 °C, and achieve excellent physical and mechanical properties. Overcome the effects of poor high temperature resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

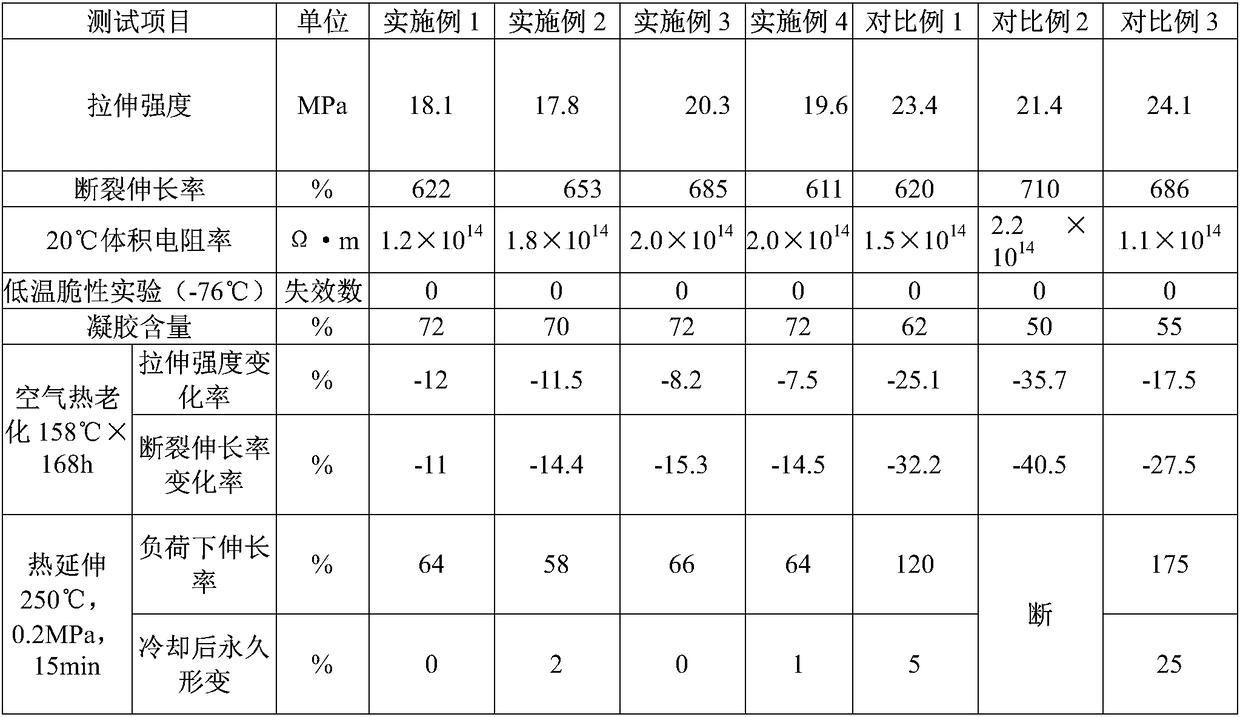

Examples

Embodiment 1

[0038] This embodiment provides a silane cross-linked polyethylene insulating material for heating cables. The raw materials and dosages used are shown in Table 1, wherein,

[0039] Among the raw materials of silane grafting material: The first high-density polyethylene is the high-density polyethylene produced by Qilu Petrochemical. The grade is: TR144, and the melt index is 0.3g / 10min;

[0040]The bimodal polyethylene is produced by Borealis, the grade is: FB2230, and the melt index is 0.2g / 10min;

[0041] The grade of polypropylene selected from PetroChina Dushanzi is: EPF30R;

[0042] The silane crosslinking agent is a mixture of vinyltrimethoxysilane, vinyltriethoxysilane and vinyl-tris(2-methoxyethoxy)silane in a weight ratio of 1:1:2 ;

[0043] Grafting initiator is dicumyl peroxide;

[0044] The first lubricant is a fluorine-containing rheological agent ppa, purchased from 3M Company;

[0045] The first antioxidant is antioxidant 300;

[0046] Among the raw mat...

Embodiment 2

[0057] This embodiment provides a silane cross-linked polyethylene insulating material for heating cables. The raw materials and dosages used are shown in Table 1, wherein,

[0058] The first high-density polyethylene is high-density polyethylene produced by Qatar Chemicals, the brand is TR131, and the melt flow rate is 0.2g / 10min; the silane crosslinking agent is vinyltrimethoxysilane. Other raw materials are identical with embodiment 1.

[0059] The preparation method is the same as in Example 1.

Embodiment 3

[0061] This embodiment provides a silane cross-linked polyethylene insulating material for heating cables. The raw materials and dosages used are shown in Table 1, wherein,

[0062] The first lubricant is a mixture of fluorine-containing rheological agent PPA and microcrystalline wax in a weight ratio of 1:1, and the grafting initiator is 1,1-di-tert-butyl peroxide-3,3,5 - Trimethylcyclohexane. Other raw materials are identical with embodiment 1.

[0063] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com