Manufacture process of protective film with no rubber residue

A manufacturing process and protective film technology, applied in the direction of film/sheet adhesives, adhesives, film/sheet release coatings, etc., to reduce surface tension, improve water resistance, and improve yellowing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

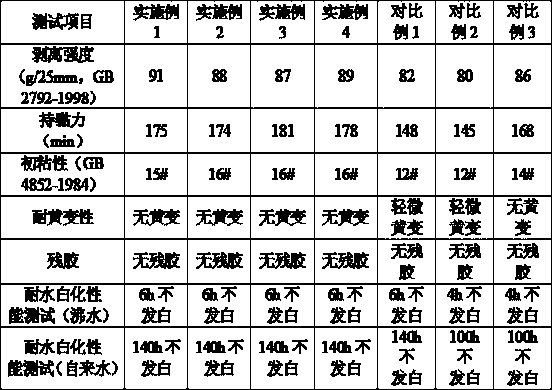

Examples

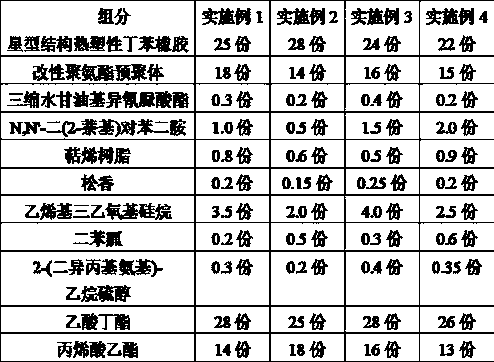

Embodiment 1~4

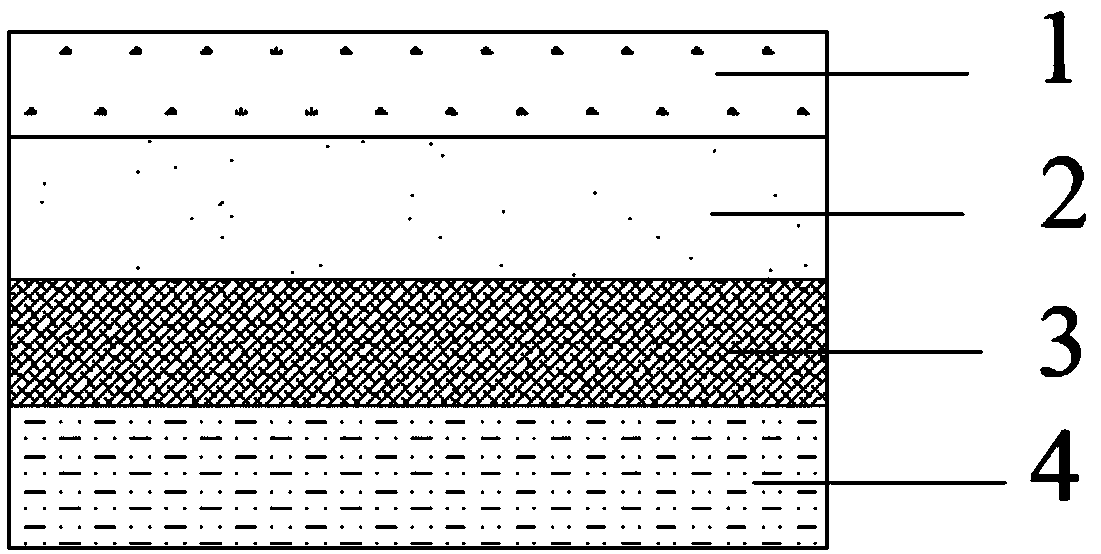

[0028] Embodiment 1~4: A kind of manufacturing process of no residual glue protective film, described protective film comprises PET breathable film 1, antistatic coating 2, modified styrene-butadiene rubber adhesive layer 3 and peeling layer 4, described antistatic The coating 2 is coated on the PET breathable film 1, the antistatic coating 2 is coated with a modified styrene-butadiene rubber adhesive layer 3, and the peeling layer 4 is compounded on the modified styrene-butadiene rubber adhesive layer 3;

[0029] The modified styrene-butadiene rubber adhesive layer 3 is made by drying the modified styrene-butadiene rubber adhesive, and the modified styrene-butadiene rubber adhesive layer 3 is obtained by the following steps:

[0030] Step 1, taking each component according to parts by weight;

[0031] Step 2. Take a reaction kettle and control the temperature in the reaction kettle to 20~25°C. First, add 25~30 parts of butyl acetate and 15~20 parts of ethyl acrylate into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com