Energy-saving-type wall painting device

An energy-saving, wall technology, applied in construction, building structure, etc., can solve the problems of inability to achieve uniformity, leakage of paint slurry, high labor intensity, etc., to improve the quality of wall construction, construction quality improvement, operation handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

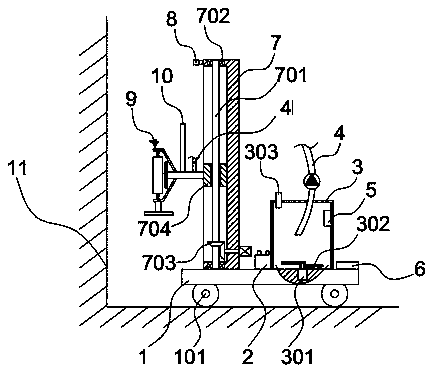

[0027] Such as Figure 1-4 As shown, the energy-saving wall painting device includes a bottom plate 1 on which a material cylinder 3 and a lifting plate 7 are arranged respectively on the top, and a liftable painting mechanism 9 is provided on the side of the lifting plate 7, and the painting mechanism 9 passes through the discharge pipe 4 and the material cylinder. 3 connection, the discharge pipe 4 is connected with a pump body, the bottom plate 1 is provided with a motor 301 whose output shaft is in the material barrel 3, the output shaft is staggered with stirring blades 302 with different heights, and the upper part of the inner wall of the material barrel 3 is at least connected with A monitor 5 and a computer 6 are arranged on the bottom plate 1 . The wall 11 is painted by mechanical equipment instead of manual painting, which reduces the labor force and improves the quality of mechanical operation. The whole painting process is monitored by the computer 6, and the para...

Embodiment 2

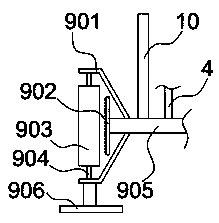

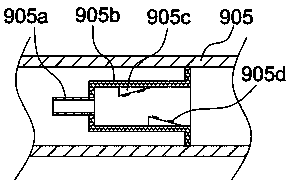

[0037] When the energy-saving wall painting device of the present invention is actually working: pour the cement slurry raw materials for painting into the barrel 3, stir the raw materials through the motor 301 to prevent the raw materials from sinking or delamination, and push the device to the wall through the roller 101 Near 11, control the brushing distance, start the pump body on the discharge pipe 4 to extract the cement mortar and transport it to the connecting pipe 905, and the spray pipe 902 will spray the mortar out to drive the roller brush wheel 903 to rotate, and spray the brush slurry to the roller brush at the same time Feed is realized on the wheel 903, and the lifting mechanism 7 drives the screw rod 701 to rotate through the bevel gear set 703 to drive the lifting block 704 to lift up and down, and drives the roller brush wheel 903 to lift up and down to paint the wall 11. After the wall 11 is painted, to improve The construction speed of the wall body can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com