Multi-condition pavement accelerated loading teaching tester

An accelerated loading and teaching test technology, applied in teaching models, instruments, educational tools, etc., can solve the problems of inability to accurately simulate the actual road surface stress conditions, actual response of the road surface, rut damage, complicated operation, etc., to achieve convenient teaching demonstration and The effects of experimental operation, convenient molding, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

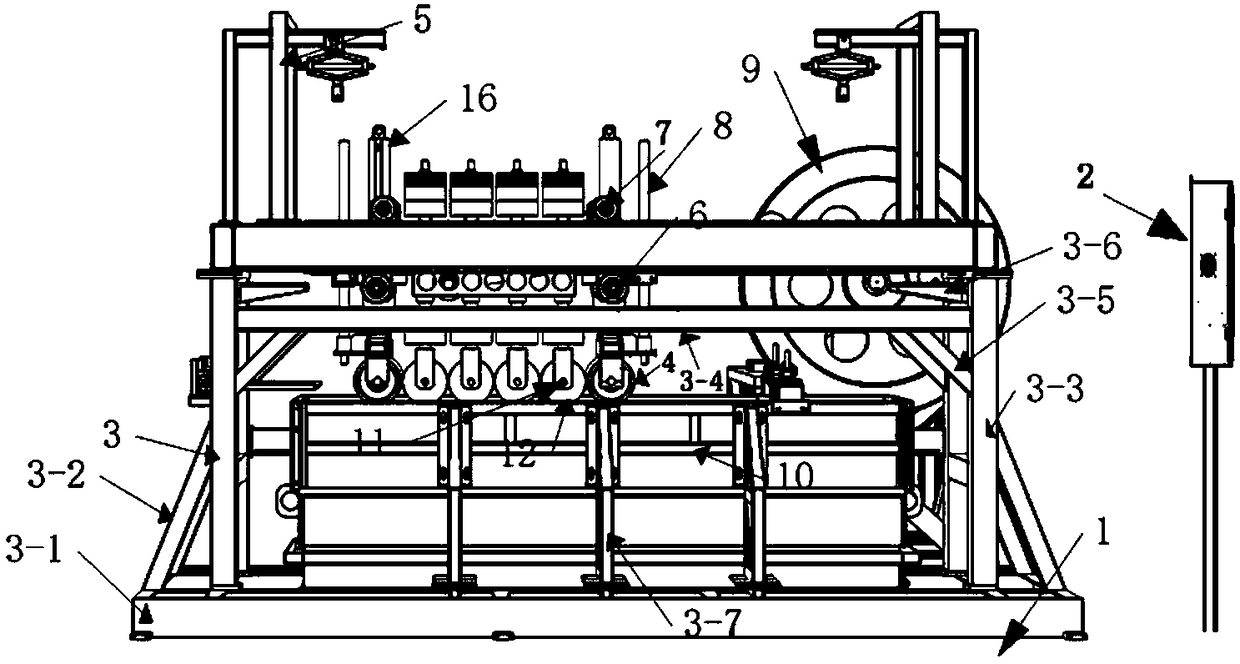

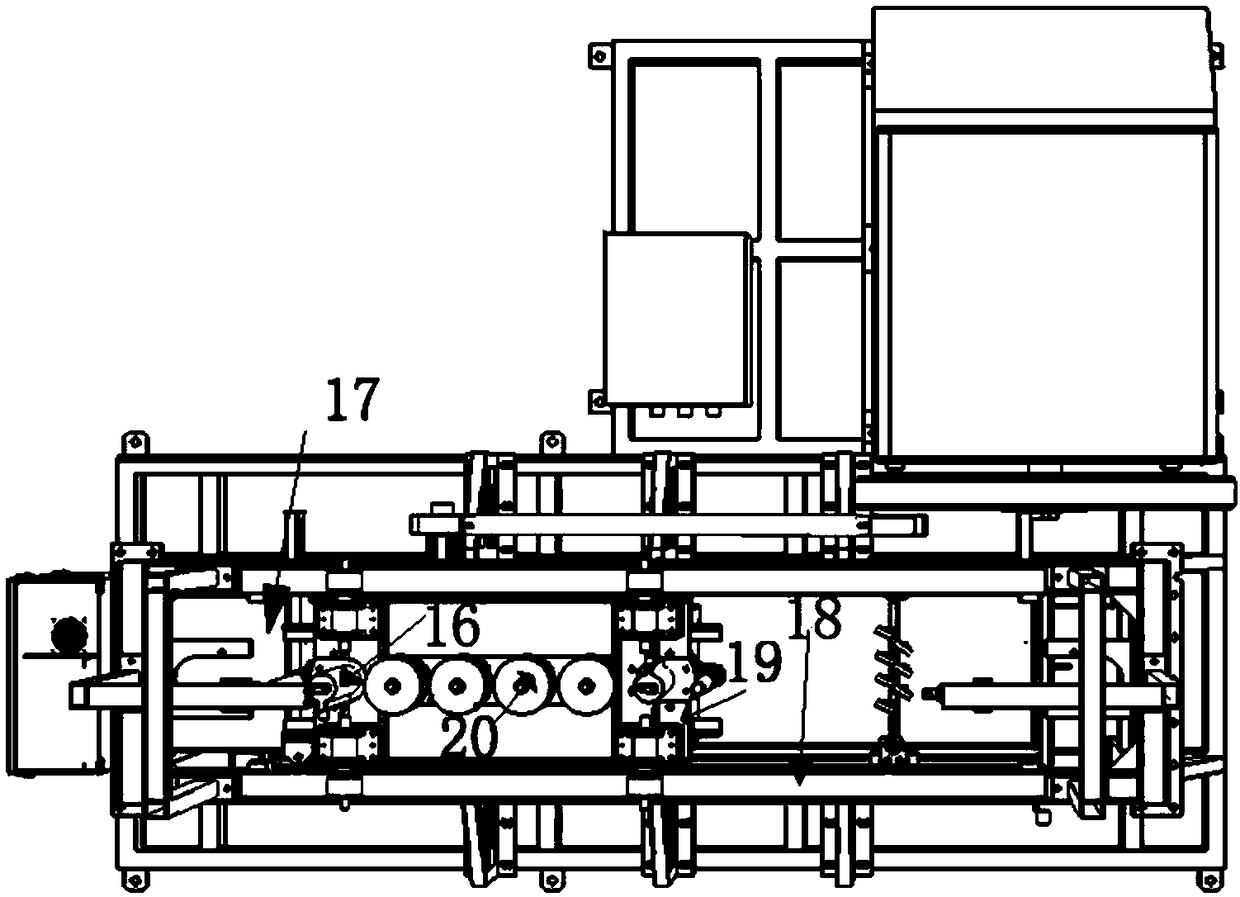

[0020] Specific implementation mode one: combine Figure 1 to Figure 5 Description, a multi-working-condition pavement accelerated loading teaching tester, the device includes a base (1), an electric control cabinet (2), a support mechanism (3), two rolling steel wheels (4), a set of rolling Pressure system lifting mechanism (5), 5 side guide wheels (6), 4 test wheel outer cylinders (7), a set of connecting brackets (8), 1 flywheel (9), road simulation test box (10), 4 detection wheel shafts (11), 4 detection wheels (12), speed reduction mechanism (13), connecting rod (14), 4 wheel sliders (15), one group of rolling oil cylinders (16), rising pallet ( 17), road roller mechanism model (18), oil cylinder fixed frame (19), one group of adjustable weights (20), scale (21), oil pump station (22), multi-point vertical displacement ruler (23).

[0021] The profile of the bracket mechanism (3) is a cuboid bracket mechanism (3) comprising a bracket chassis (3-1), 2 outer diagonal brac...

specific Embodiment approach 2

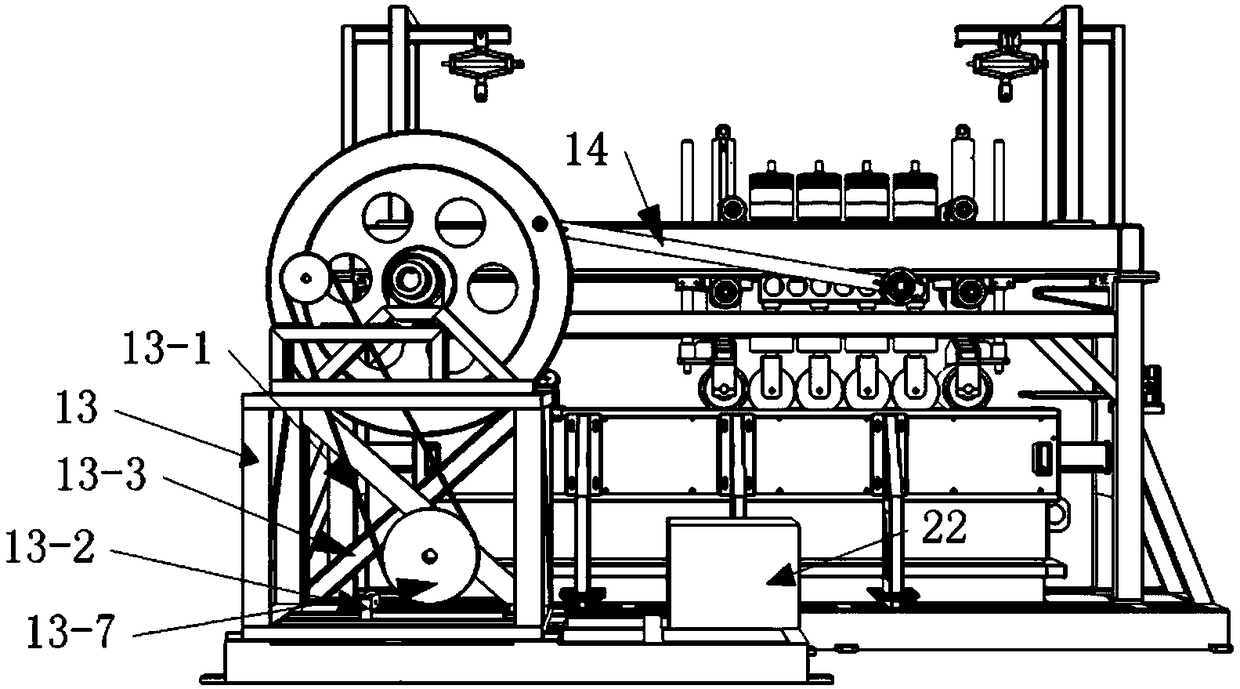

[0023] Specific implementation mode two: multi-working condition pavement accelerated loading teaching tester is characterized in that: the reduction mechanism (13) is covered by the motor cover and fixed by the frame reinforcement rib (13-3), and the interior is composed of two shaft couplings ( 13-4) Connect the flywheel shaft (13-5) through the coupling (13-6), connect the flywheel shaft (13-5) to the flywheel (9), and adjust the pulley through the motor adjustment plate (13-2) The rotating speed of (13-7) drives the belt (13-1) on the belt pulley (13-7) to rotate then, thereby plays the rate of motion of regulating flywheel (9).

specific Embodiment approach 3

[0024] Specific embodiment three: the pavement simulation test box (10) of multi-working condition pavement accelerated loading teaching tester is made up of crushed stone enclosing frame, asphalt frame, and its inside is provided with heating aluminum plate and spray frame, can simulate the test road Perform heating or watering functions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wheel width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com