Preparation method of lithium ion battery solid electrolyte interface layer, and lithium ion battery

A solid electrolyte and lithium-ion battery technology, applied in the direction of non-aqueous electrolyte batteries, electrolyte battery manufacturing, secondary batteries, etc., can solve the problems of uniform and dense solid electrolyte film, the inability to guarantee the coating layer, and the accuracy of coating equipment. Achieve the effects of excellent electronic insulation and ion conductivity, great promotion and application value, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

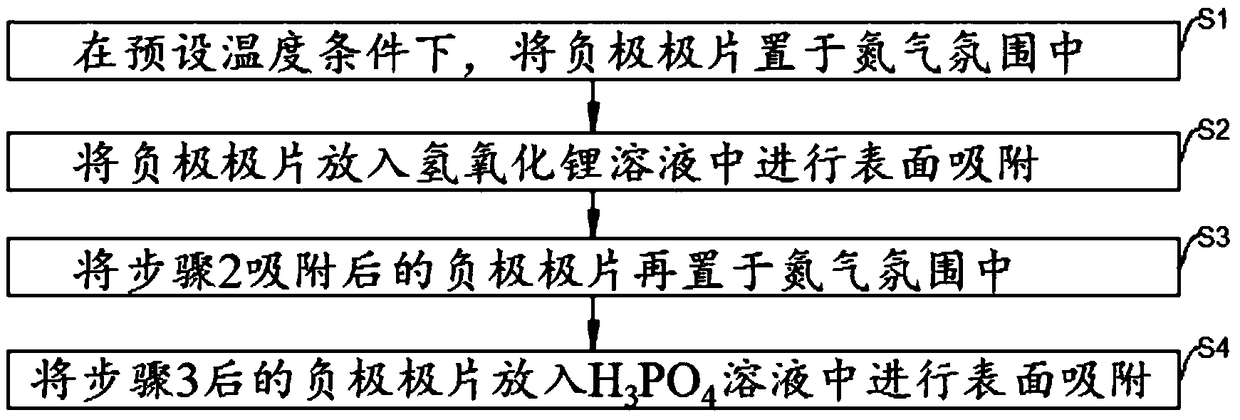

[0037]A method for preparing a solid electrolyte interface layer of a lithium-ion battery provided in this embodiment, the specific steps are as follows:

[0038] S1. Under preset temperature conditions, place the negative pole piece in a nitrogen atmosphere;

[0039] S2, putting the negative pole piece into lithium hydroxide solution for surface adsorption;

[0040] S3, placing the negative electrode sheet after the adsorption in step 2 in a nitrogen atmosphere;

[0041] S4, put the negative pole piece after step 3 into H 3 PO 4 surface adsorption in solution.

[0042] Repeat step 1 to step 4, and the number of cycles is 5 to 30 times. Preferably, the number of cycles may also be 10 to 20 times.

[0043] Wherein, in step 1, the preset temperature is -50°C to -30°C. Preferably, in this embodiment, the preset temperature is controlled at the dew point temperature of -40°C, and the nitrogen atmosphere uses high-purity nitrogen, that is, nitrogen with a purity greater than 9...

Embodiment 1

[0055] The positive electrode of the lithium-ion battery is composed of NCM, Super-P, PVDF, and the negative electrode is composed of artificial graphite, Super-P, SBR, and CMC. Deposit a layer of solid electrolyte LiPON on the surface of the pole piece, specifically, cycle the above steps 1 to 4, the number of cycles is 10 times, and then perform rolling, winding, baking, liquid injection, aging, and chemical formation.

Embodiment 2

[0057] The positive electrode of the lithium-ion battery is composed of NCM, Super-P, PVDF, and the negative electrode is composed of artificial graphite, Super-P, SBR, and CMC. Roasting, liquid injection, aging, chemical formation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com