Modular Green Roof System

A modular and green technology, applied in waterway systems, roofs, roof coverings, etc., can solve the problems of high requirements for top floor slabs, complex construction processes, and high construction costs, achieve recycling of resources, overcome weak drought resistance, The effect of improving drought resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Construction of Modular Green Roof Systems

[0028] (1) On-site investigation and pattern design

[0029] Check the location and area of the roof to be greened on site, and determine the construction scale and placement pattern of the green roof according to the site requirements. According to the climate conditions of the construction site and the characteristics of the surrounding environment, determine the flowering period and color matching scheme of the planted plants, as well as the placement scheme of the modular green roof unit (ie, the module box 1).

[0030] (2) Processing of modular green roof monomers

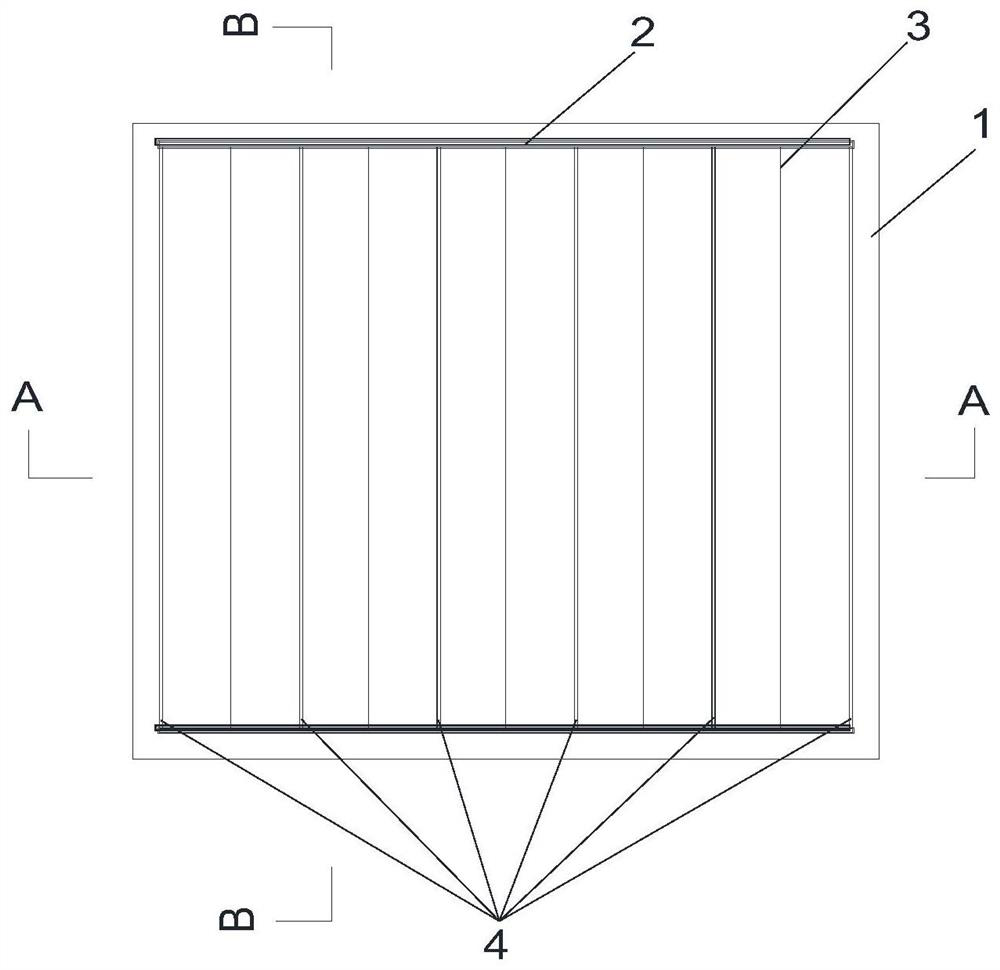

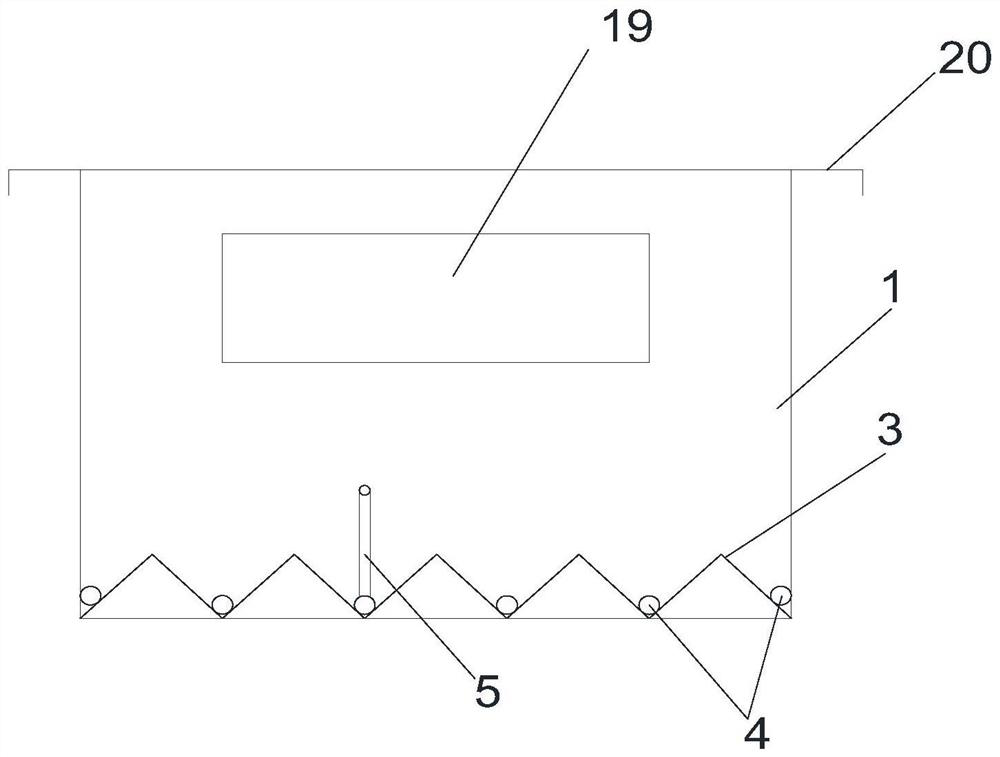

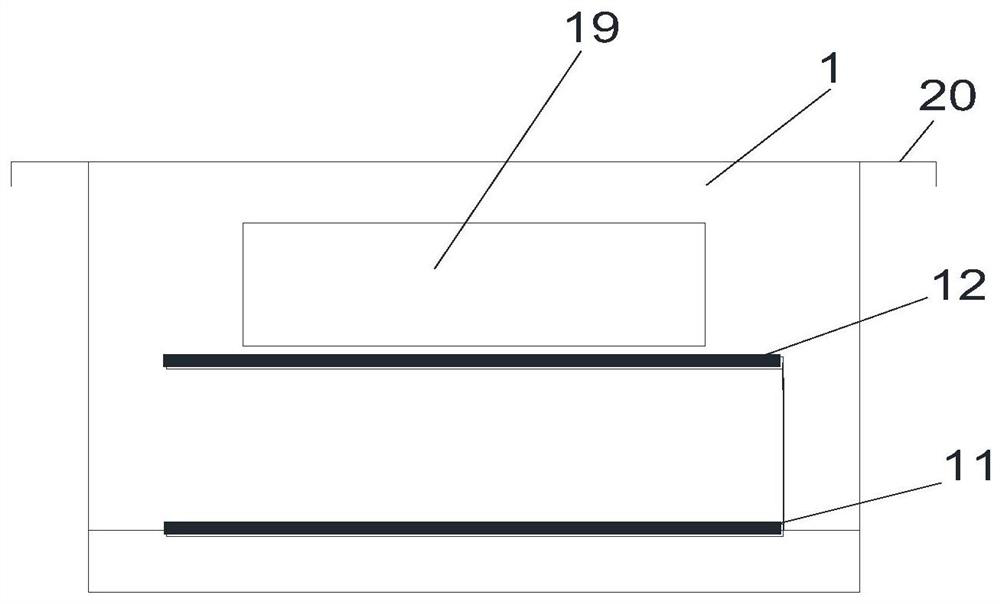

[0031] According to the on-site investigation, determine the processing quantity of the green roof monomer, and adopt the injection molding mode for one-time pouring production. as attached Figure 1-4 As shown, each green roof unit (i.e. module box 1) is a three-dimensional box structure of 500mm×500mm×350mm (length×width×depth), and 100mm×300mm ( dept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com