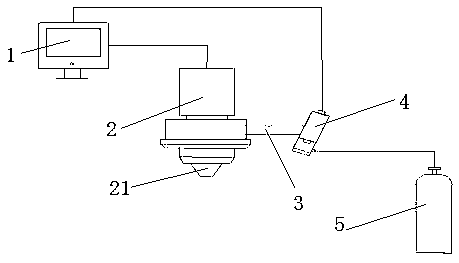

Laser welding incident angle real-time regulating and controlling system based on temperature feedback and welding method

A laser welding and temperature feedback technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of burn-through and low melting point, and achieve the effect of increasing the incident distance and preventing the phenomenon of burn-through.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

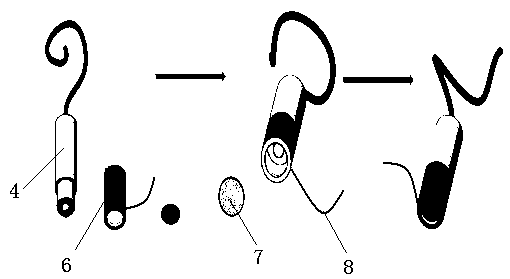

Method used

Image

Examples

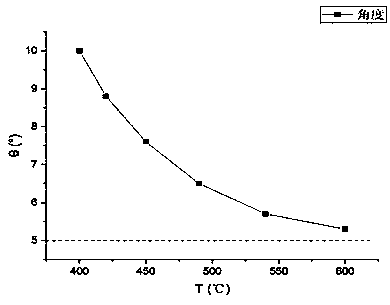

Embodiment 1

[0047] The invention performs optical fiber laser welding on the die-casting aluminum alloy heater cover plate structure of the battery of the new energy vehicle. The thickness of the aluminum alloy heater cover plate is 3mm, and the welding is carried out in the butt joint method. Argon gas is used as the shielding gas for welding. The initial laser welding incident angle is 45mm / s, and the initial laser welding incident angle is set to 8°. According to the computer display, when the temperature thermometer detects about 440°C, the angle has not changed. As the temperature exceeds 440°C and continues to increase, the infrared measurement The temperature meter feeds back to the control module, and the control module issues instructions, the incident angle of laser welding begins to decrease, and finally maintains at about 525°C, and the incident angle of laser welding is about 6°. It was found that the weld was well formed, and there were no defects such as blast holes and por...

Embodiment 2

[0049] The invention performs optical fiber laser welding on the back cover of a 7000 series aluminum alloy mobile phone of a certain brand. Butt joint welding is adopted, argon is used as protective gas for welding, the gas flow is set to 15L / min, the thickness of the back cover is about 2.5mm, the defocus is -2mm, the laser power is set to 2200W, and the welding speed is 50mm / min s, set the initial laser welding incident angle to 7°, according to the computer display, when the temperature is below about 470°, the laser incident angle is in a constant state, as the welding progresses, the temperature in a specific area continues to rise, reaching and After exceeding 470°, the control module gives feedback, the laser incident angle is changed, the welding temperature is finally maintained at 575°C, and the display angle is 5.5°. According to the welding results, the welds around the cover plate are well formed, without defects such as collapse, blast holes, and pores, and the ...

Embodiment 3

[0051] The invention performs optical fiber laser welding on the 6061 aluminum alloy cooling system of a communication equipment integrated circuit of Huawei. Butt joint welding is adopted, argon is used as shielding gas for welding, gas flow is set to 15L / min, defocus is set to -2mm, cover plate thickness is 4mm, laser power is set to 2400W, welding speed is 30mm / s, The initial welding incident angle is set to 9°. Through the observation of the computer, it is found that the temperature detected by the thermometer is always below 415°C, so the control module has not issued an instruction to adjust the angle. After the welding is completed, it can be found that the overall shape of the weld is good, the weld pattern is clear, and there are no obvious defects such as undercut, weld bumps, pores, slag inclusions, etc. According to the cutting results, it is found that there are no defects such as burn-through, which conforms to the comprehensive mechanical properties, such as I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com