Silk texture anti-skid matt glaze, preparation method and ceramic tile using silk texture anti-skid matt glaze

A matt glaze and matte glaze technology, applied in the field of architectural ceramics, can solve the problems of reducing the decorative effect of the pattern decoration layer and failing to achieve the decorative effect, and achieve high anti-skid grade, increase anti-skid resistance, and excellent wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

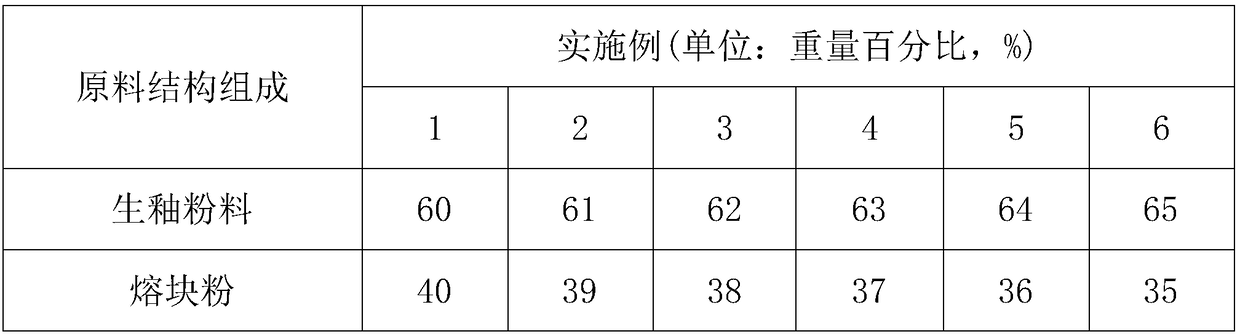

[0035] The raw material structure and composition of the silk texture and non-slip matte glazes provided in Examples 1-6 are shown in Table 1 below, the mineral composition of the raw materials is shown in Table 2 below, and the corresponding chemical composition is shown in Table 3.

[0036]

[0037] Table 1

[0038]

[0039]

[0040] Table 2

[0041]

[0042]

[0043] table 3

[0044] Examples 1-6 Prepare ceramic tiles with a silk texture and non-slip matte glaze layer on the surface according to the following steps.

[0045] Step A, select raw materials according to the raw material structure composition shown in Table 1, the raw material mineral composition shown in Table 2 and the chemical composition shown in Table 3, and add water accounting for 40% of the raw material weight;

[0046] Step B, ball milling for 9 hours to obtain the glaze slurry, controlling the fineness to 325 mesh and sieving the remainder to be 1.2% by mass, and then aging for 49 hour...

Embodiment 7

[0050] Step A, select raw materials according to the raw material structure composition, raw material mineral composition and chemical composition shown in Example 2, and add water accounting for 40% of the raw material weight;

[0051] Step B, ball milling for 8 hours to obtain the glaze slurry, controlling the fineness of 325 mesh sieve to be 0.8% by mass fraction, and then aging for 60 hours, so as to obtain a silk texture and non-slip matte glaze;

[0052] Step C, using a bell-jar glazing process to evenly apply a silk-like and non-slip matte glaze on the surface of the ceramic tile body 1;

[0053] In step D, the glazed ceramic tile body 1 is calcined at a firing temperature of 1200° C. for 120 minutes, so as to obtain a ceramic tile with a silk texture and non-slip matte glaze layer on the surface, such as figure 1 shown.

Embodiment 8

[0055] Step A, select raw materials according to the raw material structure composition, raw material mineral composition and chemical composition shown in Example 2, and add water accounting for 40% of the raw material weight;

[0056] Step B, ball milling for 10 hours to obtain the glaze slurry, controlling the fineness to 325 mesh and sieving the remainder to be 1% by mass, and then aging for 49 hours, so as to obtain a matte glaze with silk texture and non-slip;

[0057] Step C, using a bell-jar glazing process to evenly apply a silk-like and non-slip matte glaze on the surface of the ceramic tile body 1;

[0058] In step D, the glazed ceramic tile body 1 is calcined at a firing temperature of 1200° C. for 90 minutes to obtain a ceramic tile with a silk texture and a non-slip matte glaze layer on the surface, such as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com