Concrete self-healing agent, preparation method and application method

A concrete and mixture technology, applied in the field of concrete, can solve the problems of concrete safety, durability decline, waste of manpower and material resources, user hazards, etc., and achieve the effects of prolonging the service life, saving energy, and preventing water seepage and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

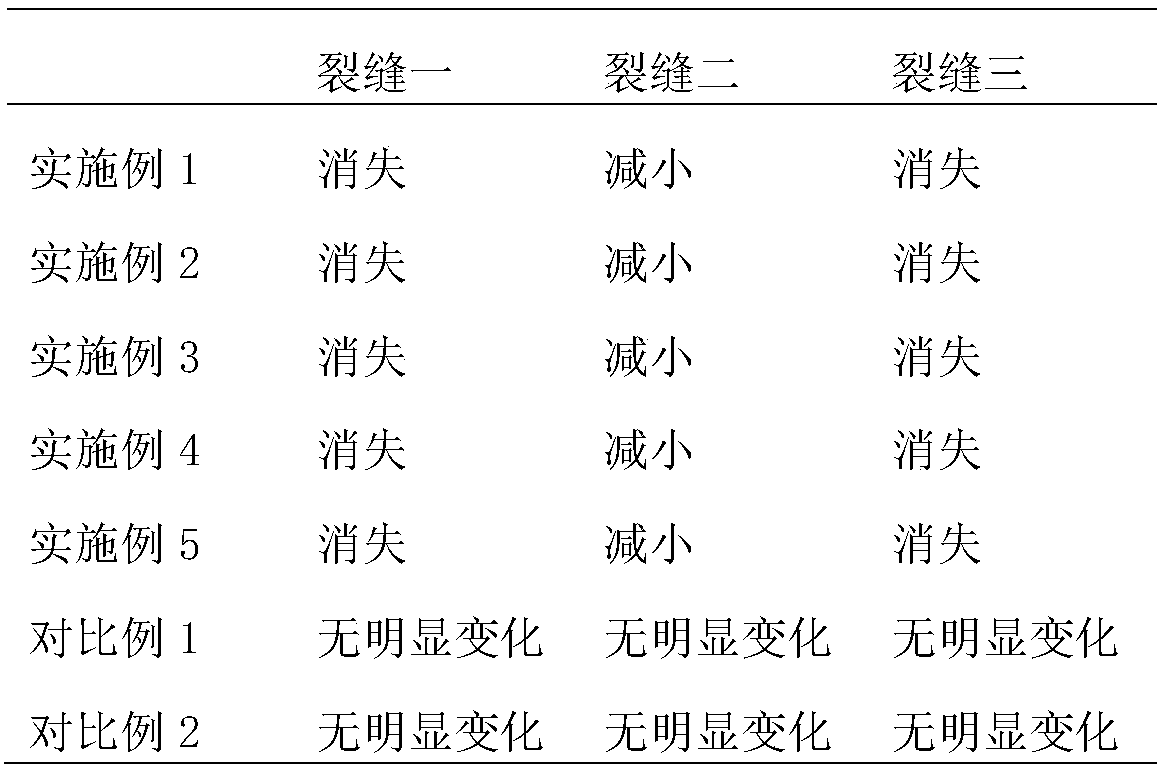

Examples

Embodiment 1

[0027] This embodiment proposes a concrete self-healing agent, comprising the following mass proportioning components:

[0028] Mineral powder 32.68, iron powder 22, bentonite 22, calcium sulfate 12, sodium sulfate 7, ammonium acrylamide 3, glyceryl stearate 0.69, titanate coupling agent 0.63.

[0029] The preparation method is:

[0030] a. Mix bentonite, calcium sulfate, sodium sulfate and iron powder evenly, heat to 100±5°C at the same time, add titanate coupling agent while stirring, and stir evenly to obtain a mixed material,

[0031] b, add 1% glyceryl stearate of the total mass of the material to the mixed material, keep the material at 90-95 ° C, stir evenly,

[0032] c, add 2% glyceryl stearate by its mass into acrylamide, keep the material at 90-95°C, stir evenly,

[0033] d. Mix the product obtained in step b, the product obtained in step c and the ore powder evenly.

[0034] A concrete applied with a concrete self-healing agent, comprising the following mass rati...

Embodiment 2

[0038] This embodiment proposes a concrete self-healing agent, comprising the following mass proportioning components:

[0039] Mineral powder 5.14, iron powder 27, bentonite 27, calcium sulfate 18, sodium sulfate 13, ammonium acrylamide 8, glyceryl stearate 1.01, titanate coupling agent 0.85.

[0040] The preparation method is:

[0041] a. Mix bentonite, calcium sulfate, sodium sulfate and iron powder evenly, heat to 100±5°C at the same time, add titanate coupling agent while stirring, and stir evenly to obtain a mixed material,

[0042] b. Add glyceryl stearate of 1% of the mass of material a to the mixed material, keep the material at 90-95°C, and stir it evenly with a high-speed mixer.

[0043] c, add 2% glyceryl stearate by mass to acrylamide, keep the material at 90-95°C, stir evenly with a high-speed mixer,

[0044] d. Mix the product obtained in step b, the product obtained in step c and the ore powder evenly.

[0045] A concrete applied with a concrete self-healing...

Embodiment 3

[0049] This embodiment proposes a concrete self-healing agent, comprising the following mass proportioning components:

[0050] Mineral powder 21.46, iron powder 25, bentonite 22, calcium sulfate 15, sodium sulfate 10, acrylamide ammonium 5, glyceryl stearate 0.82, titanate coupling agent 0.72

[0051] The preparation method is:

[0052] a. Mix bentonite, calcium sulfate, sodium sulfate and iron powder evenly, heat to 100±5°C at the same time, add titanate coupling agent while stirring, and stir evenly to obtain a mixed material,

[0053] b, adding 1% glyceryl stearate by mass to the mixed material, keeping the material at 90-95°C, stirring at a high speed evenly,

[0054] c, add its mass 2% glyceryl stearate to acrylamide, keep the material at 90-95°C, stir at high speed evenly,

[0055] d. Mix the product obtained in step b, the product obtained in step c and the ore powder evenly.

[0056] A concrete applied with a concrete self-healing agent, comprising the following ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com