Autoclaved brick and method for preparing same

A technology of autoclaved bricks and manufacturing methods, which is applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of limited development of autoclaved bricks, and achieve the effects of improved heat exchange effects, increased ultimate pressure, and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

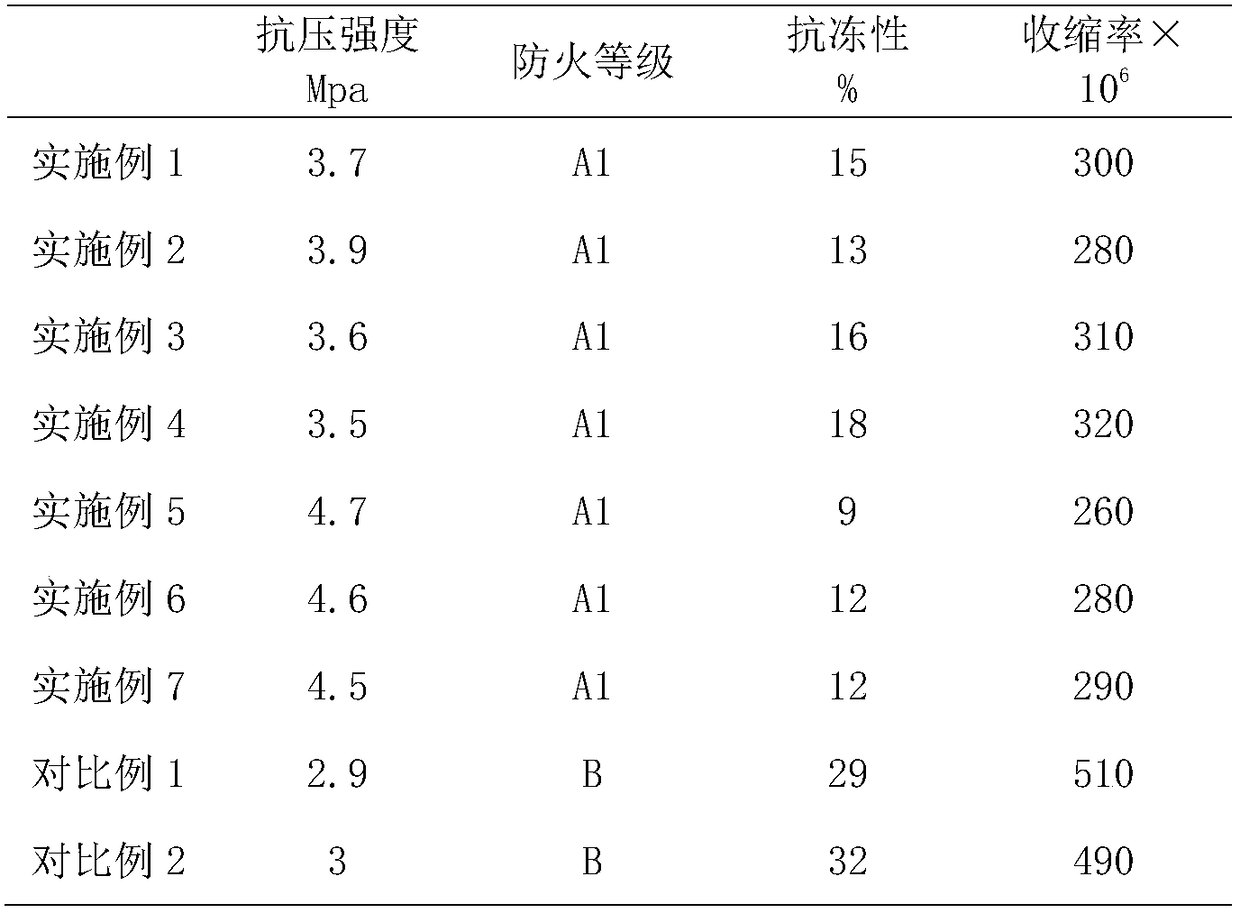

Examples

Embodiment 1

[0045] An autoclaved brick: fly ash 50, slag 5, tailing sand 5, iron oxide black 2, carbide slag 6, quicklime 4, water 7.

[0046] The preparation method is:

[0047] a: According to the above mass ratio, the above components are crushed and mixed uniformly to obtain a mixed material,

[0048] c: digest and age the mixed material obtained in step a for 2-4 hours,

[0049] d: Wheel mill the digested material for 3-5 minutes,

[0050] e: Pressing and molding the material obtained in step d, the molding pressure is 15-20MPa, applying pressure in stages to obtain bricks,

[0051] f: The brick adobe is kept at 15-35°C and the humidity is 70%-95%, and then after vacuuming, it is maintained at 190-220°C for 6-8 hours under autoclaved pressure to obtain an autoclaved brick product.

[0052] Staged pressure includes,

[0053] S1, applying a pressure of 15-20MPa to the material obtained in step d for 8-10s;

[0054] S2, canceling the pressure,

[0055] Repeat the S1-S2 operation a...

Embodiment 2

[0057] An autoclaved brick: fly ash 53, slag 6, tailing sand 7, iron oxide black 2.5, carbide slag 7, quicklime 5, water 10.

[0058] The preparation method is:

[0059] a: According to the above mass ratio, the above components are crushed and mixed uniformly to obtain a mixed material,

[0060] c: digest and age the mixed material obtained in step a for 2-4 hours,

[0061] d: Wheel mill the digested material for 3-5 minutes,

[0062] e: Pressing and molding the material obtained in step d, the molding pressure is 15-20MPa, applying pressure in stages to obtain bricks,

[0063] f: The brick adobe is kept at 15-35°C and the humidity is 70%-95%, and then after vacuuming, it is maintained at 190-220°C for 6-8 hours under autoclaved pressure to obtain an autoclaved brick product.

[0064] Staged pressure includes,

[0065] S1, applying a pressure of 15-20MPa to the material obtained in step d for 8-10s;

[0066] S2, canceling the pressure,

[0067] Repeat the S1-S2 operation ...

Embodiment 3

[0069] An autoclaved brick: fly ash 55, slag 7, tailing sand 10, iron oxide black 3, carbide slag 8, quicklime 6, water 12.

[0070] The preparation method is:

[0071] a: According to the above mass ratio, the above components are crushed and mixed uniformly to obtain a mixed material,

[0072] c: digest and age the mixed material obtained in step a for 2-4 hours,

[0073] d: Wheel mill the digested material for 3-5 minutes,

[0074] e: Pressing and molding the material obtained in step d, the molding pressure is 15-20MPa, applying pressure in stages to obtain bricks,

[0075] f: The brick adobe is kept at 15-35°C and the humidity is 70%-95%, and then after vacuuming, it is maintained at 190-220°C for 6-8 hours under autoclaved pressure to obtain an autoclaved brick product.

[0076] Staged pressure includes,

[0077] S1, applying a pressure of 15-20MPa to the material obtained in step d for 8-10s;

[0078] S2, canceling the pressure,

[0079] Repeat the S1-S2 operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com