Force-sensitive color-changing self-repairing intelligent polyester elastomer and preparation method thereof,

A polyester elastomer, self-healing technology, applied in the field of force-sensitive discoloration self-healing intelligent polyester elastomer and its preparation, polyester material, to achieve the effects of high yield, enhanced stress capacity, and simple post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

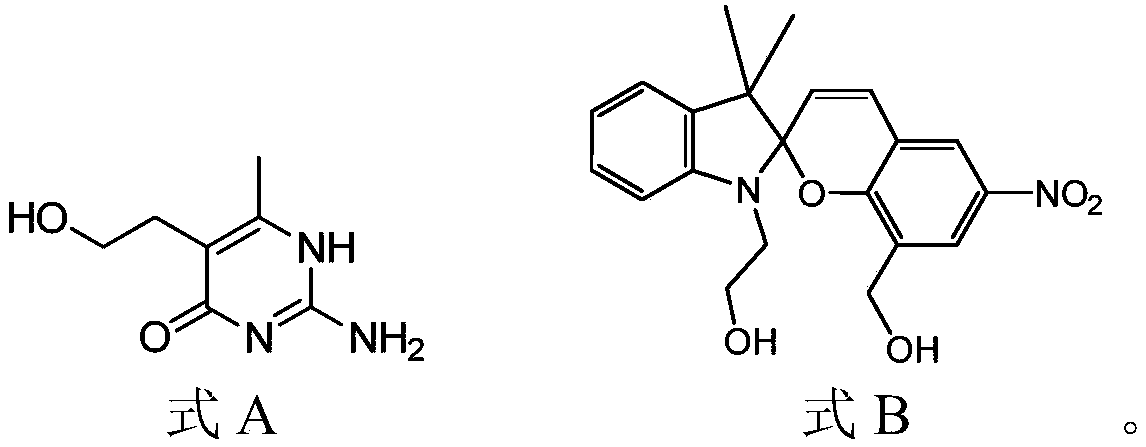

[0072] 1) Weigh 1.90 g of pyrimidinone derivatives, 3.8 g of hexamethylene diisocyanate, and 14.3 mg of dibutyltin dilaurate, and react at 70° C. for 12 hours under nitrogen atmosphere to obtain 4.9 g of diisocyanate containing ureido pyrimidone structure.

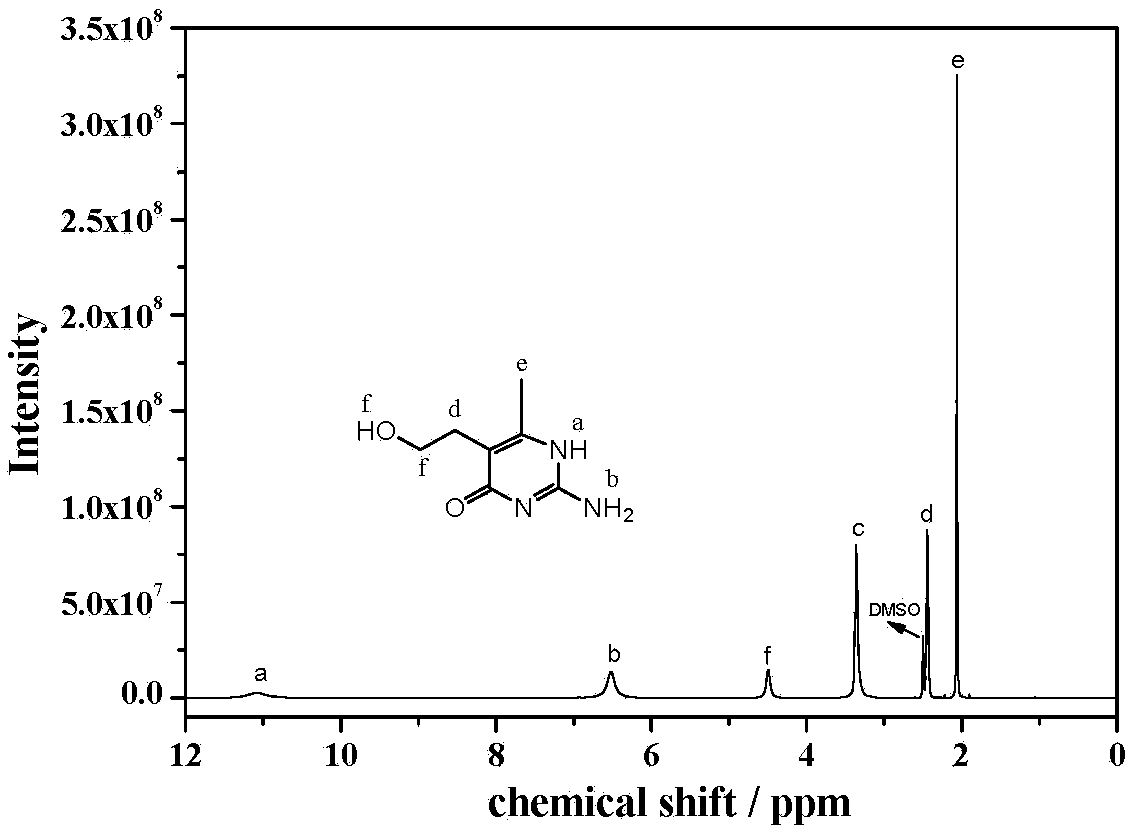

[0073] Among them, the pyrimidinone derivatives used in this example are the structural formula shown in the description formula A and the specific synthetic route disclosed in the description, and the accompanying drawings figure 1 Its data representation map is given, combined with figure 1 It can be seen that various hydrogen atoms in the molecular structural formula shown in formula A have been correspondingly characterized on the map, which also shows that the pyrimidinone derivative of this example was prepared by using the synthetic route in the specification.

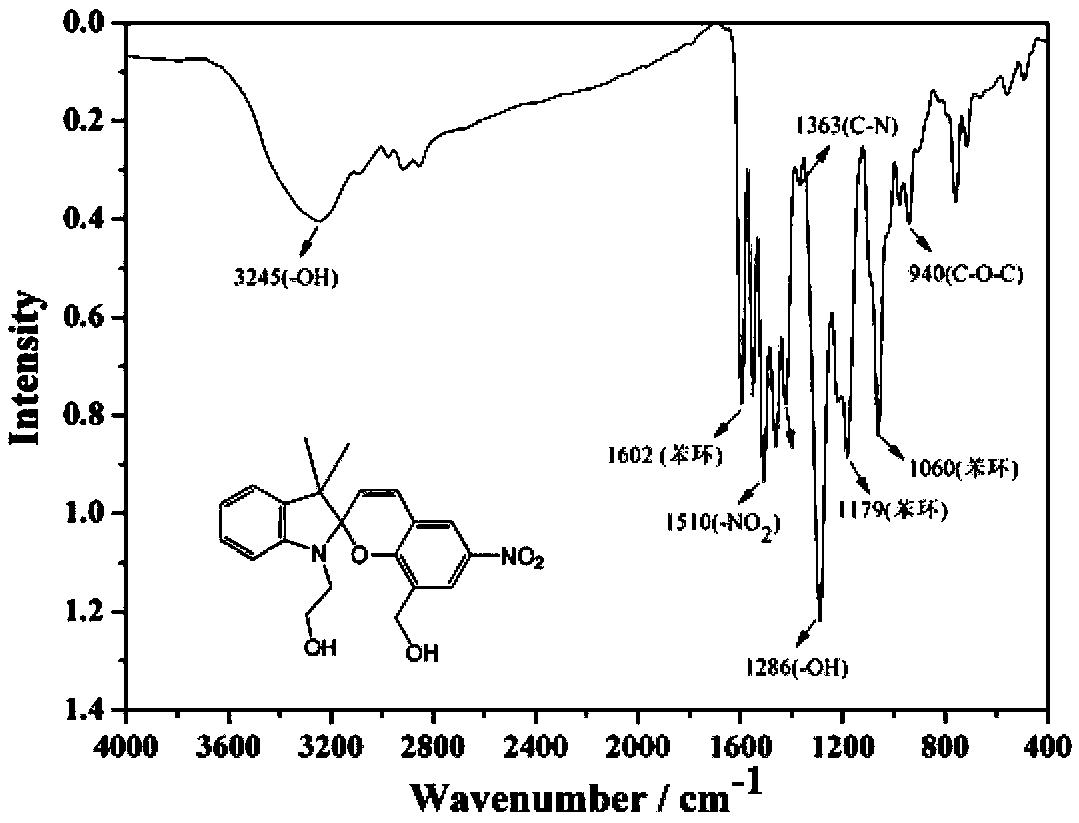

[0074] 2) Weigh 1.6g of spiropyran derivative, 4.9g of diisocyanate containing ureidopyrimidinone structure, 6.2mg of dibutyltin dilaurate, 12ml of nitrogen...

Embodiment 2

[0079] 1) Weigh 2.0 g of pyrimidone derivatives, 4.2 g of hexamethylene diisocyanate, and 15 mg of dibutyltin dilaurate, and react at 70° C. for 12 hours under nitrogen atmosphere to obtain 5.3 g of diisocyanate containing ureido pyrimidone structure.

[0080] 2) Weigh 1.74g of spiropyran derivative, 5.3g of diisocyanate containing ureidopyrimidinone structure, 6.7mg of dibutyltin dilaurate, 12ml of nitrogen nitrogen dimethylformamide, the reaction temperature is 25°C, and after 1 hour of reaction Purification waited till product 5.0 g.

[0081] 3) Weigh 34g of terephthalic acid, 18.6g of 1,4-butanediol, 12g of polytetramethylene glycol (2000g / mol), and 0.08g of tetrabutyl titanate, mix them uniformly, add them to the reactor, and fill them with nitrogen for replacement Then heat up to 220°C, vacuumize, add 3g polytetramethylene glycol (2000g / mol) after reacting for 3 hours; after reacting for 4h and the pressure drops to 10kPa, heat up to 245°C for polycondensation reaction, ...

Embodiment 3

[0084] 1) Weigh 2.3 g of pyrimidone derivatives, 4.7 g of hexamethylene diisocyanate, and 18.1 mg of dibutyltin dilaurate, and react at 70° C. for 12 hours under nitrogen atmosphere to obtain 5.9 g of diisocyanate containing ureido pyrimidone structure.

[0085] 2) Weigh 2.0g of spiropyran derivative, 5.9g of diisocyanate containing ureidopyrimidinone structure, 7.6mg of dibutyltin dilaurate, and 15ml of nitrogen nitrogen dimethylformamide. Purification waited till product 5.5g.

[0086] 3) Weigh 33g of terephthalic acid, 18.1g of 1,4-butanediol, 12g of polytetramethylene glycol (2000g / mol), and 0.09g of tetrabutyl titanate, mix them uniformly, add them to the reactor, and replace them with nitrogen Then heat up to 220°C, vacuumize, add 3g polytetramethylene glycol (2000g / mol) after reacting for 3 hours; after reacting for 4h and the pressure drops to 10kPa, heat up to 245°C for polycondensation reaction, when the stirring torque reaches the set value When , the reaction ends...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com