Method for removing aflatoxin M1 in liquid system by using lactobacillus rhamnosus

A technology of Lactobacillus rhamnosus and aflatoxin, applied to Lactobacillus, bacteria used in food preparation, application and other directions, can solve the problems of degradation method limitation, detoxification effect is not as strong as chemical method, etc., to overcome technical problems , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Preparation of test strains:

[0047] Lactobacillus rhamnosus CICC20255

[0048] Lactobacillus rhamnosus CICC20255 was cultured to the end of the logarithm, and the bacterial liquid and 50% (v / v) glycerol were mixed evenly at a volume ratio of 1:1, and stored at -20°C. Before use, Lactobacillus rhamnosus CICC20255 was inoculated in MRS medium at an inoculation amount of 2% (v / v), cultured at 37° C. for 12 hours, and activated by two passages. The activated strains were counted on the plate, and the concentration of the bacterial solution was adjusted to 2.5×10 9 CFU / mL. Centrifuge the bacterial solution in a refrigerated centrifuge at 4°C and 8000r / min for 10min, wash the precipitate twice with phosphate buffer (pH6.0), and place the obtained bacteria in a blast drying oven at 37°C Dry for 1 h and store at -20°C for subsequent use.

[0049] Calculation method of aflatoxin M1 removal rate:

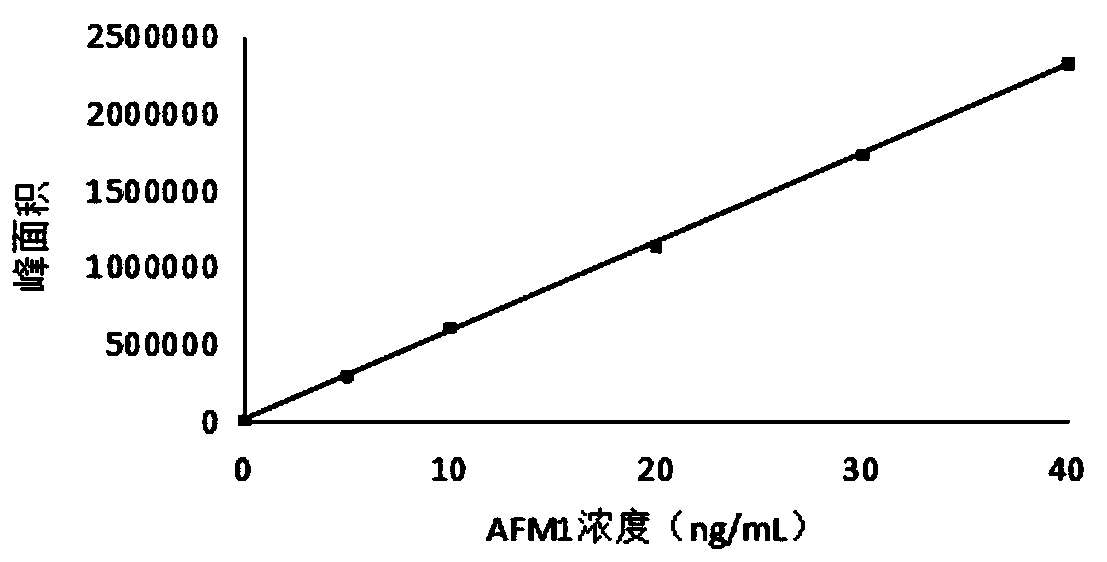

[0050] (1) Detection conditions

[0051] The high-performance liquid chromat...

Embodiment and comparative example 1

[0066] (1) Strain pretreatment

[0067] Get the above-mentioned Lactobacillus rhamnosus CICC20255 test strain prepared above, and do the following treatments respectively:

[0068] High temperature treatment: suspend the bacteria in 4mL pH6.0 PBS, heat at 100°C for 60min;

[0069] Sterilization treatment: suspend the bacteria in 4mL pH6.0 PBS, autoclave at 121°C for 60min;

[0070] Acid treatment: suspend the bacteria in 4mL acid treatment solution and shake for 1h;

[0071] Alkali treatment: Suspend the bacteria in 4mL of alkali treatment solution and shake for 1h.

[0072] The treated suspension was centrifuged at 4° C., 8000 r / min for 10 min, and the precipitate was washed 3 times with PBS (pH 6.0) to obtain bacterial cell precipitate.

[0073] (2) Adjust the pH of the liquid system containing aflatoxin M1

[0074] Configure 25ng / mL AFM1 in PBS and adjust the pH to 6.0.

[0075] (3) Add the Lactobacillus rhamnosus pretreated in step (1) to the liquid system obtained in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com