Application of DHA fat composition to soft capsules, soft capsules, and preparation method of soft capsules

A technology of oil composition and soft capsule, applied in the field of food processing, can solve the problems of unfavorable DHA and EPA supplementing human health, adjusting the ratio of DHA and EPA, easily causing abnormal bleeding, etc., so as to prevent senile dementia and reduce anisidine. value, the effect of reducing blood coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

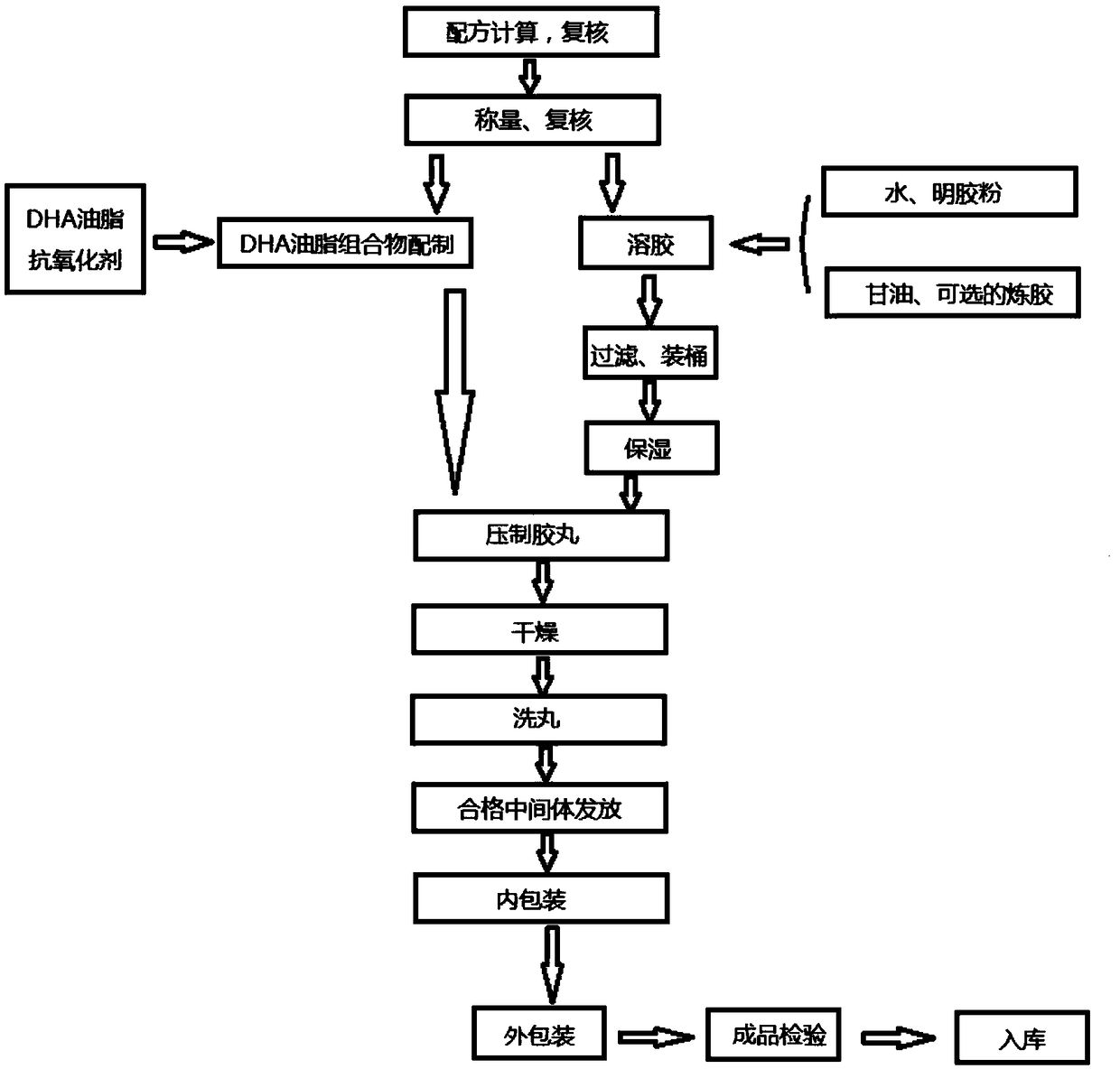

[0045] According to the second aspect of the present invention, the present invention provides a kind of preparation method of soft capsule, this method comprises:

[0046] (1) water, gelatin powder and glycerin are mixed and carry out sol, obtain sol mixture;

[0047] (2) pouring the DHA oil composition into the sol mixture to obtain soft capsules;

[0048] Wherein, the DHA oil composition contains DHA oil, and the DHA oil contains DHA and EPA;

[0049] The applicable objects of the soft capsule are pregnant women, infants and adolescents, and in the DHA oil composition, the content ratio of DHA to EPA is greater than 12:1;

[0050] The applicable objects of the soft capsule are middle-aged and elderly people. In the DHA oil composition, the content ratio of DHA to EPA is not greater than 8:1.

[0051] According to the present invention, the selection of greases for different applicable objects has been introduced in detail in the first aspect above, and will not be repeate...

Embodiment approach

[0062] According to a preferred embodiment of the present invention, the method also includes drying the perfused product. The drying can be performed according to conventional methods in the art. However, the inventors of the present invention found that the Drying is divided into two stages of primary drying and secondary drying, which can further adjust and control the softness and hardness of the finished product, and control, slow down and control the cracking of the finished capsule. Wherein, the conditions for the primary drying include: the humidity is not more than 80%, preferably not more than 65% (preferably 60-65%), the temperature is 26-32°C, and the time is 4-8 hours; the conditions for the secondary drying Including: the humidity is not greater than 45%, preferably not greater than 30% (preferably 25-30%), the temperature is 30-45°C, the relative humidity is ≤30%, and the time is 4-8 hours. Wherein, the temperature of primary drying is lower than the temperature...

Embodiment 1

[0073] This embodiment is used to illustrate soft capsule provided by the present invention and preparation method thereof

[0074] (1) Sol

[0075] The sol pot is steam sterilized for 15-30 minutes before production, including the inlet and outlet nozzles. Then the water (100 parts by weight) required for glue preparation is heated to boiling and sucked in the colloidal sol pot, and the stirring is started. Under stirring conditions, glycerin (45 parts by weight) and medicinal gelatin powder (power value 190Bloom g) (100 parts by weight) are inhaled into a sol pot sequentially, stirred and dissolved, and sold at 75° C. and a steam pressure of 0.2 MPa for 45 minutes. After the sol is finished, when the temperature drops to about 60°C, the sol mixture is filtered and vacuum degassed in sequence, and then kept warm for later use, and the storage time does not exceed 48 hours.

[0076] (2) Preparation of DHA oil composition

[0077]Under the condition that the ambient temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com